Inspection well

A technology for inspection wells and supervisors, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of waste of cultivated land resources, unfavorable environmental protection, long construction time, etc., and achieve convenient construction, fast and flexible installation, and scientific and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

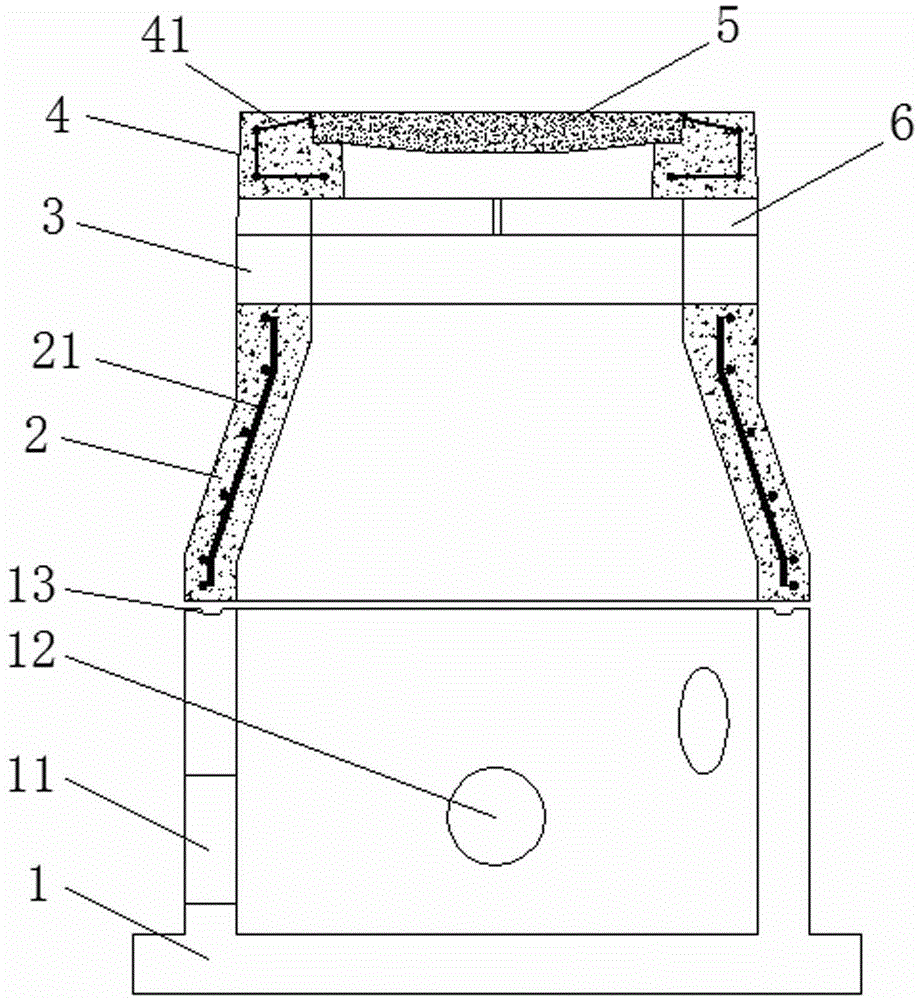

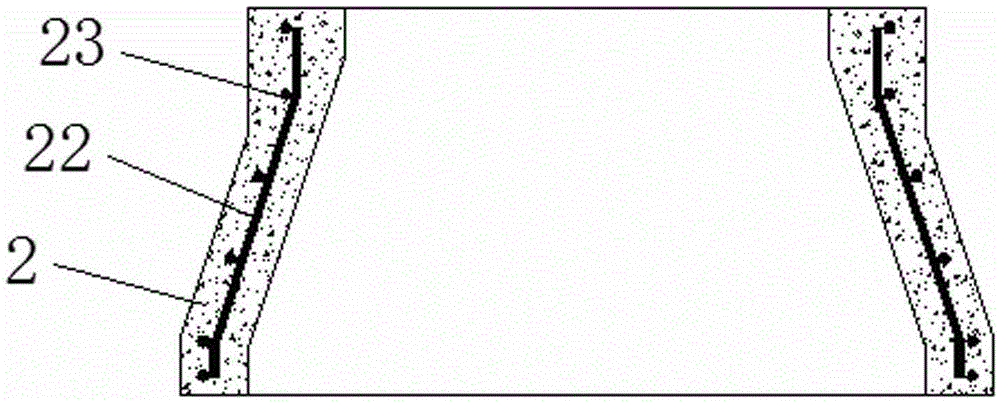

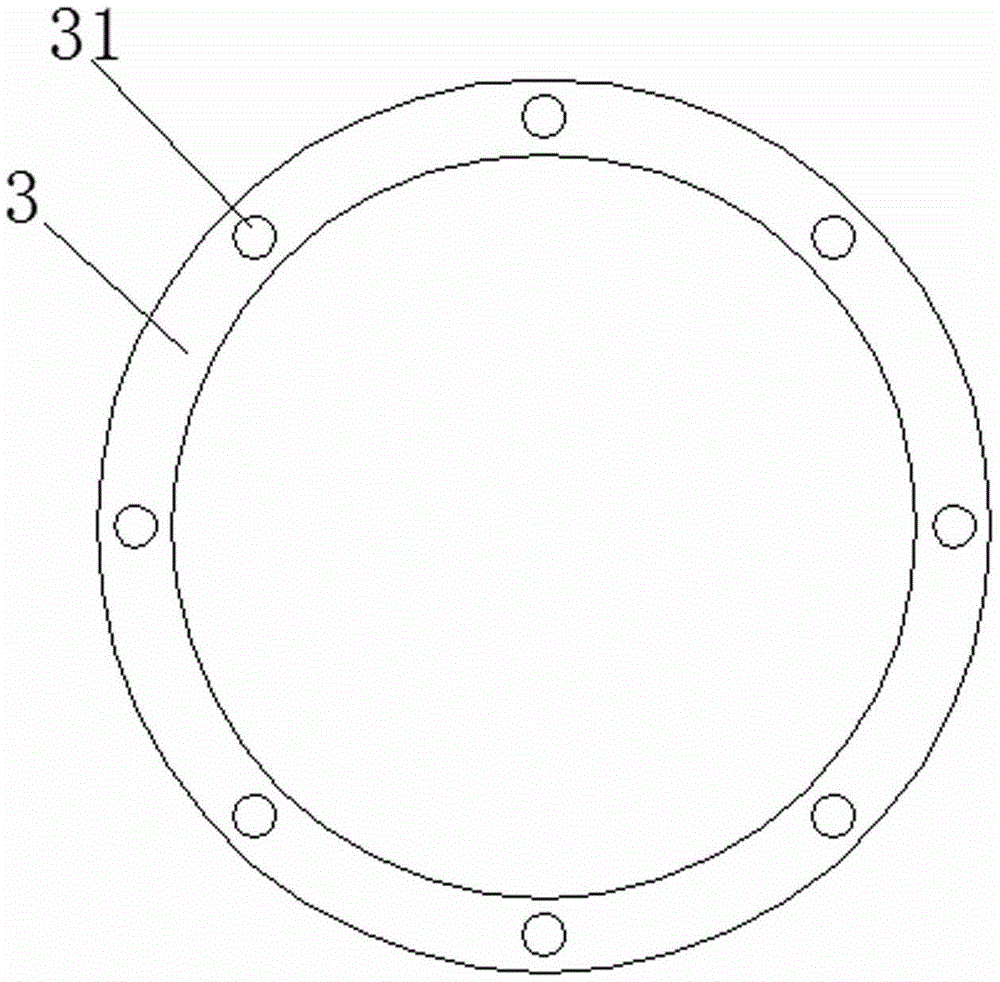

[0029] Such as Figure 1-6 As shown, an inspection well includes a base 1, and the base 1 is provided with a main pipe hole 11 and a plurality of outlet holes 12 for branch pipes, and a height adjustment part is provided above the base 1, and the height adjustment part A top section 4 is arranged above the top section 4, and a manhole cover 5 is arranged on the top section 4, and any two adjacent surfaces between the base 1, the height adjustment part and the top section 4 are connected by concrete. Specifically, the height adjustment part includes a diameter reducing joint 2 for adjusting the diameter of the well, an adjusting joint 3 and an adjusting gasket 6 for increasing the height, and the number of the diameter reducing joint 2, the adjusting joint 3 and the adjusting gasket 6 Set according to the depth of the well, and the inner diameter and outer diameter of the adjacent ends of the reducing joint 2, the adjusting joint 3 and the adjusting gasket 6 are all consistent....

Embodiment 2

[0037] Such as Figure 7 As shown, when there are few users connected to the inspection well and the burial depth of the main pipe is relatively shallow, a small-diameter base 1 can be directly selected, and the base 1 is directly connected to the top section 4, and the top section 4 is covered with the manhole cover 5.

[0038]When in use, first connect the main pipe to the main pipe through the main pipe hole 11, and then connect the branch pipe to the main pipe. If the branch pipe passes through the outlet hole 12 to communicate with multiple users, the joint of the pipe adopts a sealing rubber ring and a flexible seal. The material is connected and sealed, and then the height adjustment part, the top section 4 and the well cover 5 are installed according to the height of the inspection well. The base 1, the height adjustment part and any two adjacent surfaces of the top section 4 are sealed by concrete connection, which is effective Greatly improved the integrity and imper...

Embodiment 3

[0040] Such as Figure 8 As shown, the base 1 is set as a split structure, the split structure includes a lower base 14 and an upper base 15, the upper surface of the lower base 14 is provided with a lower main pipe hole 111, and the lower base 15 of the upper base 15 The upper main pipe hole 112 is arranged on the surface, the lower main pipe hole 111 and the upper main pipe hole 112 are semicircular holes, and the lower main pipe hole 111 and the upper main pipe hole 112 are correspondingly arranged to form a full circle main pipe hole, and the lower base 14 and the height of the upper base 15 is reduced, the casting molding is more convenient and fast, and the lower main pipe hole 111 and the upper main pipe hole 112 can be directly formed to reduce secondary processing; in addition, the upper surface of the lower base 14 is provided with positioning Slot 16, the lower surface of the upper base 15 is provided with a positioning platform 17, the positioning groove 16 matches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com