Custom environment-friendly paper machine for office and home use

A custom, paper machine technology, applied in papermaking, textiles and papermaking, waste paper processing, etc., can solve the problems of production efficiency impact, general deinking effect, slow beating and deinking speed, etc., and achieve high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

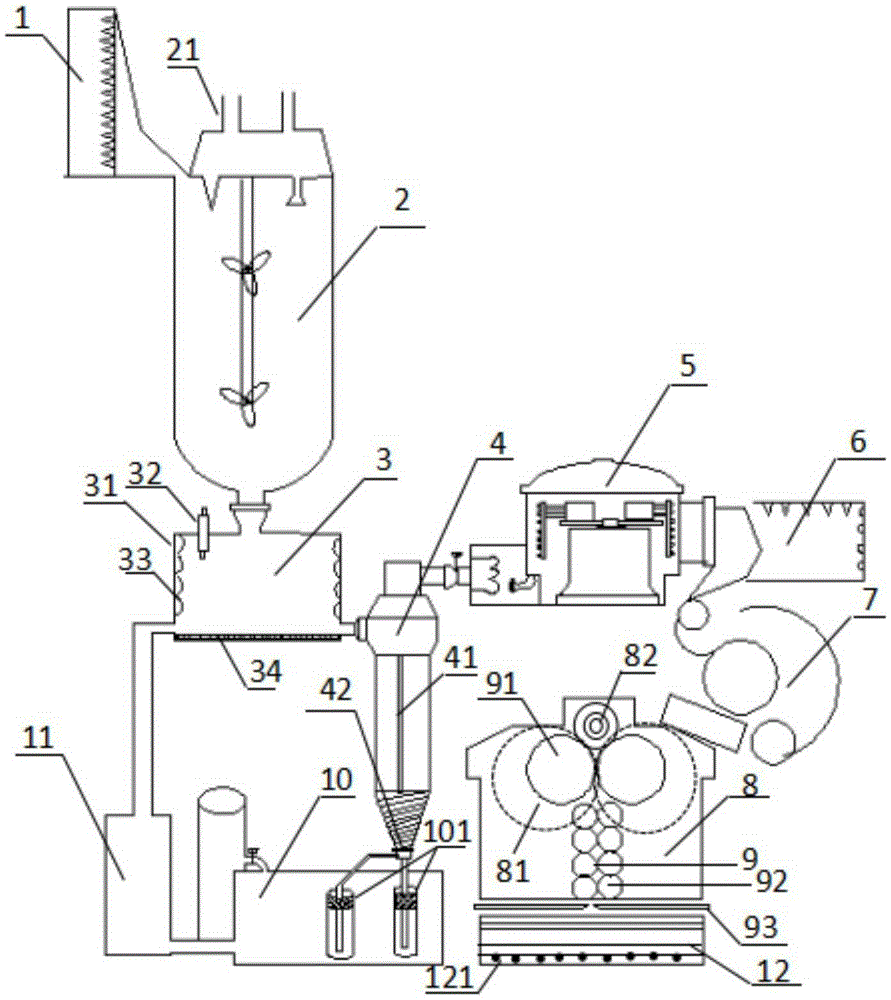

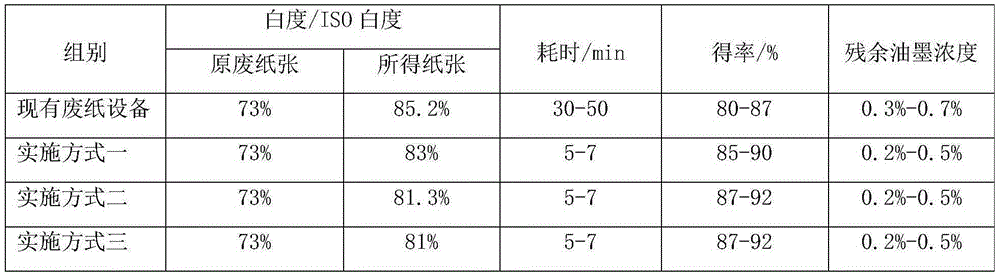

[0031] Such as figure 1 , a self-defined environmentally friendly paper machine for office use, including a shredding unit 1, a pulping unit 2, a deinking unit 3, a slag removal unit 4, a pulp washing unit 5, a coloring pulp washing unit 6, and a color fixing auxiliary agent washing unit 7. Pulping unit 8, paper forming unit 9, the above units are connected in sequence through pipelines, wherein, the center of the slag removal unit 4 is provided with a central electrode 41, and the deinking unit 3 is composed of a box body 31, an enzyme dropper 32 , an ultrasonic system 33 and an ink-loving net 34, the enzyme dropper 32 is arranged above the box body 31, the ultrasonic system 33 is arranged on both sides inside the box body 31, and the ink-loving net 34 is arranged on the box body 31 Bottom, the ink repellent mesh 34 is made of talc and hydrated magnesium silicate.

[0032] Put a piece of 70g A4 paper into the toothed paper shredder 1, the paper is sent into the overall equip...

Embodiment 2

[0035] Such as figure 1 , a self-defined environmentally friendly paper machine for office use, is characterized in that it includes a paper shredding unit 1, a pulping unit 2, a deinking unit 3, a slag removal unit 4, a pulp washing unit 5, a coloring pulp washing unit 6, and a color fixing assistant A pulp washing unit 7, a pulping unit 8, and a paper forming unit 9, the above units are connected in sequence through pipelines, wherein a central electrode 41 is arranged in the center of the slag removal unit 4, and the deinking unit 3 is composed of a box body 31, an enzyme The liquid dropper 32, the ultrasonic system 33, and the ink-loving net 34 are composed, the enzyme liquid dropper 32 is arranged on the top of the box body 31, the ultrasonic system 33 is arranged on both sides inside the box body 31, and the ink-friendly net 34 is set At the bottom of the tank 31, the ink repellent mesh 34 is made of talc and hydrated magnesium silicate.

[0036] Put a piece of 100g A4 ...

Embodiment 3

[0039] Such as figure 1 , a self-defined environmentally friendly paper machine for office use, is characterized in that it includes a paper shredding unit 1, a pulping unit 2, a deinking unit 3, a slag removal unit 4, a pulp washing unit 5, a coloring pulp washing unit 6, and a color fixing assistant A pulp washing unit 7, a pulping unit 8, and a paper forming unit 9, the above units are connected in sequence through pipelines, wherein a central electrode 41 is arranged in the center of the slag removal unit 4, and the deinking unit 3 is composed of a box body 31, an enzyme The liquid dropper 32, the ultrasonic system 33, and the ink-loving net 34 are composed, the enzyme liquid dropper 32 is arranged on the top of the box body 31, the ultrasonic system 33 is arranged on both sides inside the box body 31, and the ink-friendly net 34 is set At the bottom of the tank 31, the ink repellent mesh 34 is made of talc and hydrated magnesium silicate.

[0040] Put a piece of 120g A4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com