Polyarylene material

A technology of aryl and aralkyl, applied in the field of polyarylene materials, can solve problems such as limited solubility and limited use of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

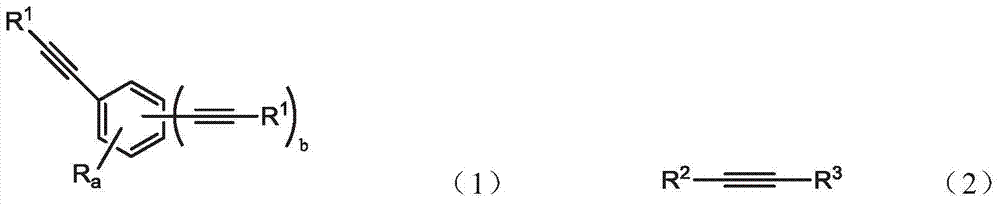

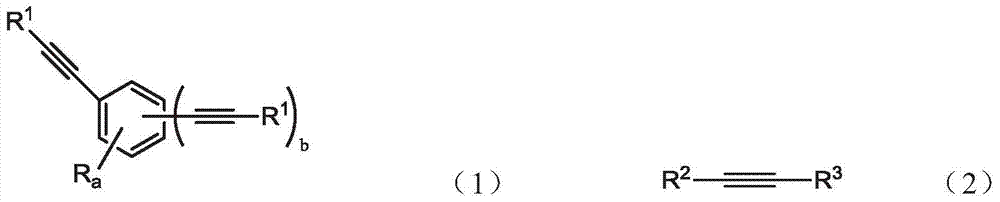

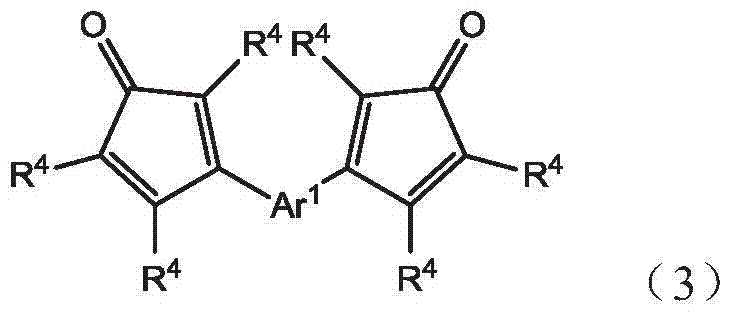

Method used

Image

Examples

example 1

[0048] Example 1. DPO-CPD (6.21 g, 7.93 mmol), 1,3-DEB (1.00 g, 7.93 mmol) and propiolic acid (0.056 g, 0.79 mmol) were added via a powder funnel to a multi-neck round bottom flask containing a stir bar, The reaction solvent ethoxybenzene (40 mL) was then added. The reaction was stirred gently at room temperature. The flask was then equipped with a reflux condenser and an internal thermocouple probe attached to a self-regulating thermostat attached to a heating mantle, and placed under a nitrogen atmosphere. Next, the dark maroon contents of the flask were warmed to an internal temperature of 130°C and maintained at this temperature for 22 hours before being cooled to 25°C by removing the heating element. The resulting orange-red solution was bottled and evaluated as a crude mixture. GPC of the resulting oligomer (Oligomer 1) indicated M as determined using polystyrene standards. w It is 13900 Da.

example 4

[0049] Example 4. The procedure of Example 3 was repeated multiple times using DPO-CPD as the first monomer, 1,3-DEB or 1,4-DEB as the second monomer, and the third monomer listed in Table 1 . The weight average molecular weights of the resulting oligomers are also reported in Table 1.

[0050] Table 1

[0051] Oligomer ID

[0052] 8

example 5

[0053] Example 5. Evaluate the solubility of oligomers in various organic solvents. Each oligomer was formulated by adding 5 g of a 30% solution of the reaction product along with 5 g of ethoxybenzene (EB) to a vial to make a 15% diluted polymer solution. 1 g of polymer solution was added to a 20 mL clear vial. The solvent MMP, PGMEA or PGME / PGMEA (30:70 v / v) mixture was added dropwise to the vial until a persistent precipitation was observed or until the solution became cloudy or until a maximum of 10 g of solvent was added. The amount of solvent added in grams to the weight ratio of 1 g of polymer solution is reported in Table 2.

[0054] Table 2

[0055]

[0056] The higher the ratio in Table 2, the more soluble the oligomer in the solvent. The above data show that oligomers formed using 1,4-DEB as the second monomer are more soluble in organic solvents than corresponding oligomers formed from 1,3-DEB. These data further show that oligomers of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com