Process for the preparation of ether compounds

A technology of ether compound and compound, which is applied in the field of preparation of ether compound represented by the following formula, can solve problems such as difficulty in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

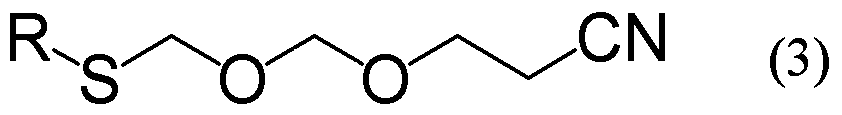

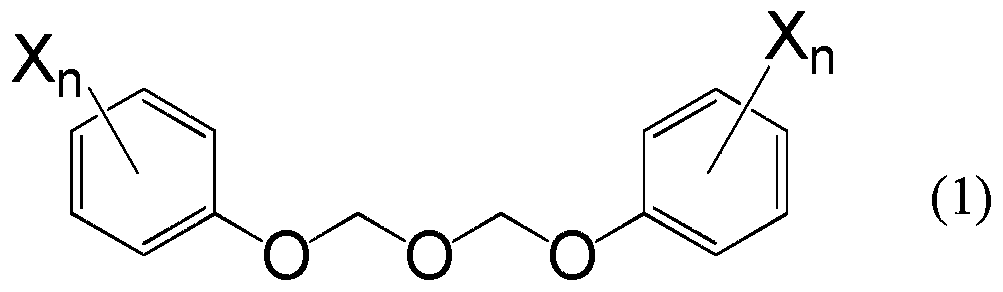

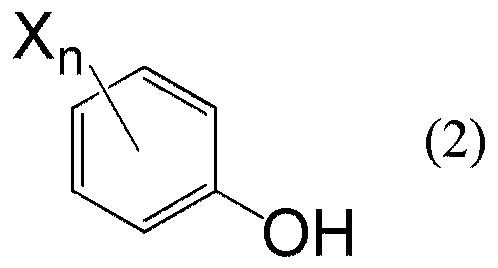

[0048] The preparation of the compound represented by formula (1) is described below.

[0049] Compounds represented by formula (1) can be produced by reacting bis(acetoxymethyl) ether with compounds represented by formula (2):

[0050]

[0051] wherein n and X have the same meanings as above.

[0052] The reaction is usually carried out in an organic solvent in the presence of a metal catalyst.

[0053]Examples of the compound represented by the formula (2) include phenol, 4-chlorophenol, 4-nitrophenol, 4-cyanophenol, 2,4-dichlorophenol, 2,4,6-trichlorophenol, 2, 3,6-Trichlorophenol, 2,3,5,6-tetrachlorophenol, 2,3,4,6-tetrachlorophenol, 2,3,4,5,6-pentachlorophenol, 2,6- Dichloro-4-nitrophenol, 2,6-dichloro-4-cyanophenol, 2,4,6-tribromophenol, 2,3,4,5,6-pentabromophenol, 2,6- Dibromo-4-cyanophenol and 2,3,4,5,6-pentafluorophenol.

[0054] Examples of organic solvents include toluene, xylene, mesitylene, dichlorobenzene, and o-dichlorobenzene. Preference is given to usi...

Embodiment

[0064] Hereinafter, the present invention will be further specifically described with reference to Examples and the like.

[0065] First, production examples of ether compounds will be described.

preparation example 1-1

[0066] Preparation Example 1-1 (Steps A to C)

[0067] To 800 ml of 2-methoxyethanol, add 100 g (95.0 g of pure content) of bis(2,4,6-trichlorophenoxymethyl) ether containing 5% by weight of aluminum oxide and 50% of water 91.4 g (pure content 45.7 g, 3.0 equivalents) of sodium methanethiolate, followed by stirring at 100 to 105° C. under a nitrogen atmosphere for 4 hours. The reaction mixture was cooled to room temperature, and filtered. Thereafter, hexane and 10% NaOH aqueous solution were added, followed by stirring. The mixture was left standing, and then separated. The obtained organic solvent layer was dried over anhydrous sodium sulfate, and then the solvent was distilled off under normal pressure, thereby obtaining 32.2 g of bis(methylthiomethyl)ether (referred to as compound Y) as a residue .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com