injection molding machine

A technology of injection molding machine and mold clamping mechanism, applied in the field of injection molding machines, can solve the problems of undocumented configuration, difficulty in operation of a circuit breaker 6 for power cut off, and difficulty in operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

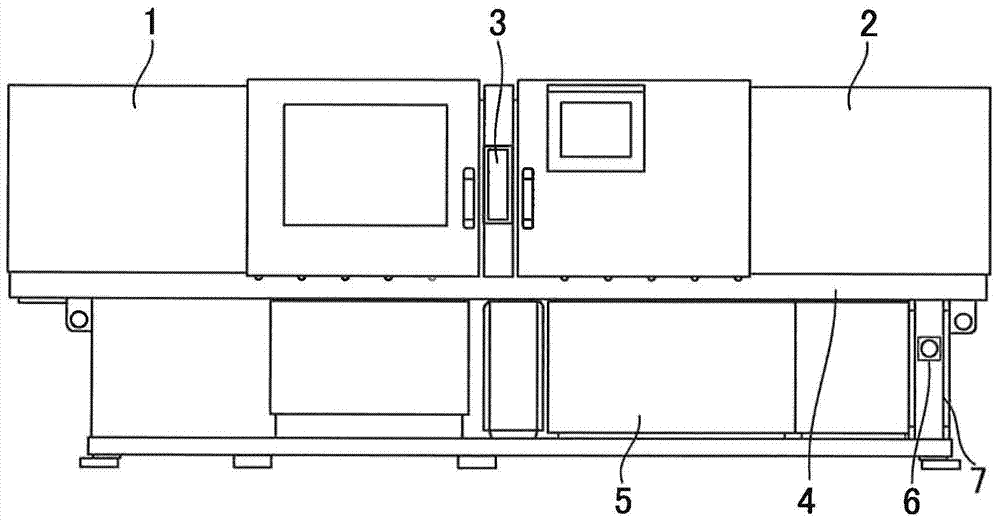

[0025] First, use Figure 1 to Figure 3 A first embodiment of the injection molding machine of the present invention will be described.

[0026] Such as figure 1 As shown, the injection molding machine includes: a mold clamping mechanism 1 that opens and closes a metal mold and generates mold clamping force; an injection mechanism 2 that is arranged opposite to the mold clamping mechanism 1 and melts resin and injects it into the metal mold; The operation panel 3 used to operate the injection molding machine; the machine table 4; and the electrical equipment part 5 that drives the mold clamping mechanism 1 and the injection mechanism 2. The operation panel 3 is disposed facing the front of the injection molding machine. The mold clamping mechanism 1 and the injection mechanism 2 are mounted on a machine base 4 . The electrical equipment unit 5 is arranged inside the machine base 4 .

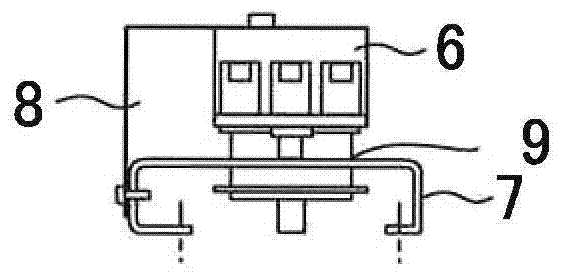

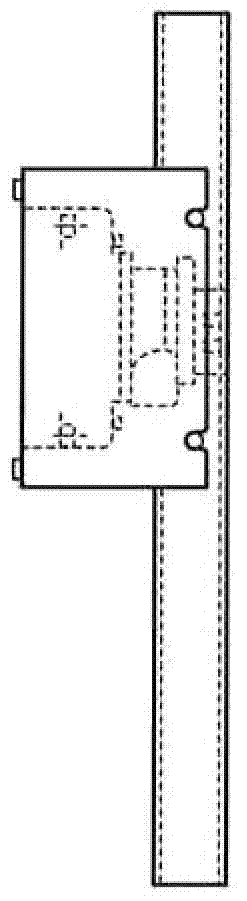

[0027] The pillar 7 constituting the machine table 4 is composed of a columnar member wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com