Acid Steam Cleaner with Integrated Level Tube, Filling Funnel, and Drain Valve

A cleaner and acid steaming technology, which is applied in the field of acid steaming cleaners, can solve the problems of secondary pollution, blast drying box or unclean air, and the inhaled air is not strictly filtered and purified, so as to avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] One, embodiment 1: acid steam cleaner

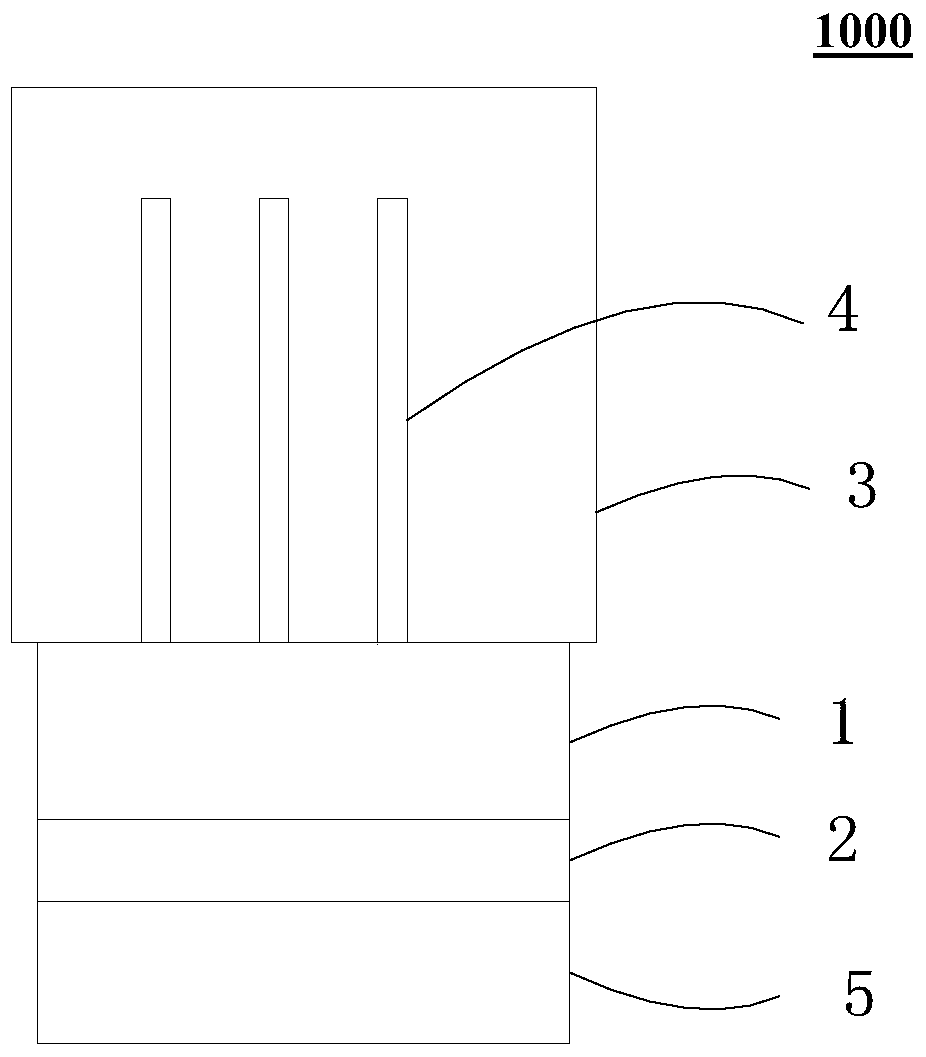

[0064] figure 1 A schematic block diagram showing the structural composition of an acid steam cleaner 1000 for automatically acid steam cleaning of tubular vessels according to an embodiment of the present invention is shown.

[0065] Such as figure 1 As shown, the acid steam cleaner 1000 includes an original acid solution container 1 , a heater 2 , a cleaning chamber 3 , a plurality of acid steam, water, and gas ejection components 4 , and a base 5 .

[0066] The original acid solution container 1 accommodates the original acid solution. Heater 2 heats the raw acid container portion to obtain hot acid vapor. A plurality of acid vapor, water and gas ejection parts 4 are installed in the cleaning chamber 3, and when the vessel is cleaned, the vessel can be set on the acid vapor, water and gas ejection part 4. Each acid steam, water, gas ejection part 4 has the acid steam path for acid steam entering and ejecting, the water / air ...

Embodiment 2

[0088] Two, embodiment 2: acid steam cleaner

[0089] Figure 5 A schematic structural view of an acid steam cleaner 2000 according to another embodiment of the present invention is shown, Figure 5 Acid Steam Cleaner 2000 shown with figure 1 The difference of the shown acid steam cleaner 1000 is that there are more water / air shower nozzles 6. As the name suggests, the top of the water / air shower nozzle 6 is in the form of a shower, and is distributed with a plurality of fine holes for Enter the water / air shower nozzle and spray from the fine holes.

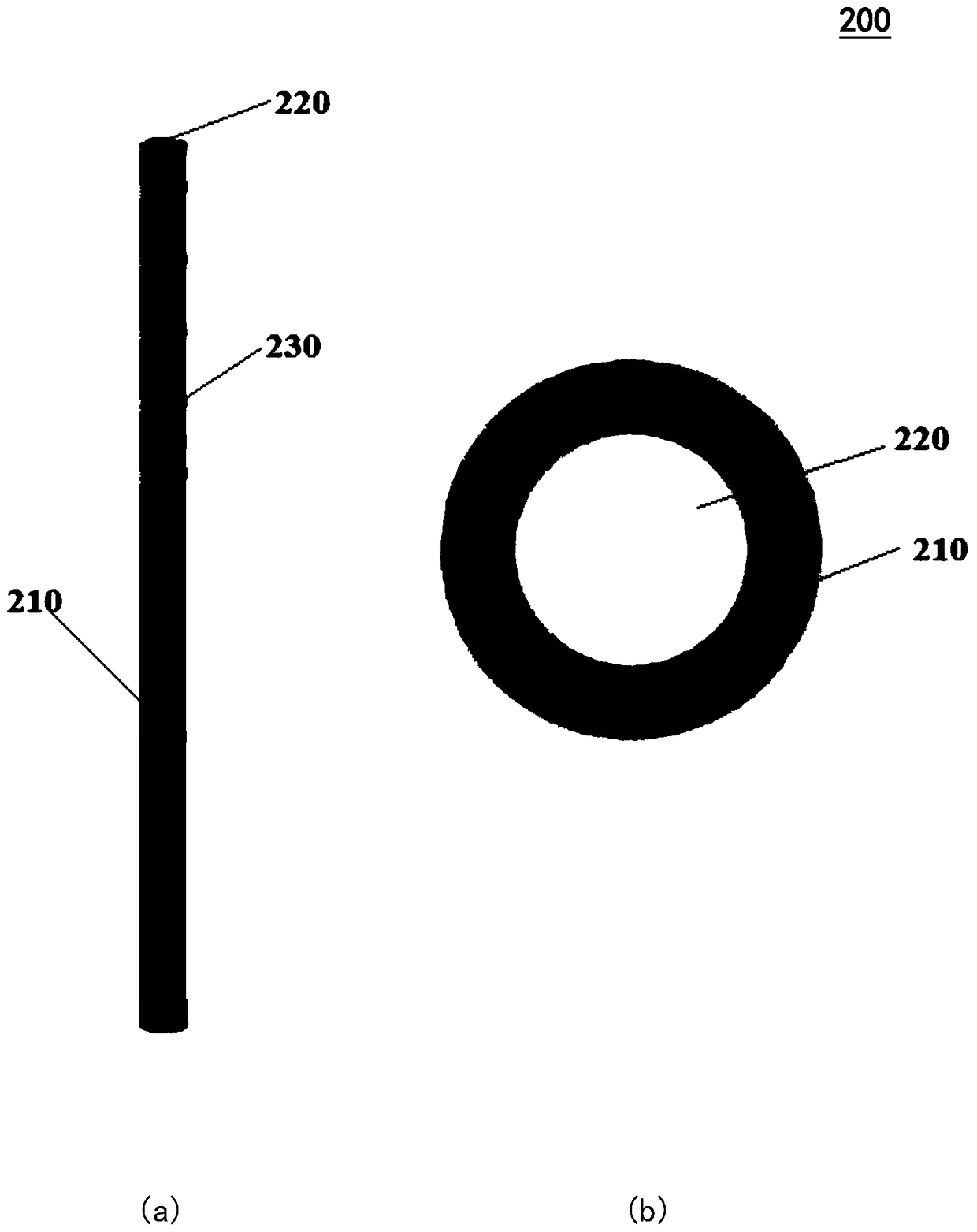

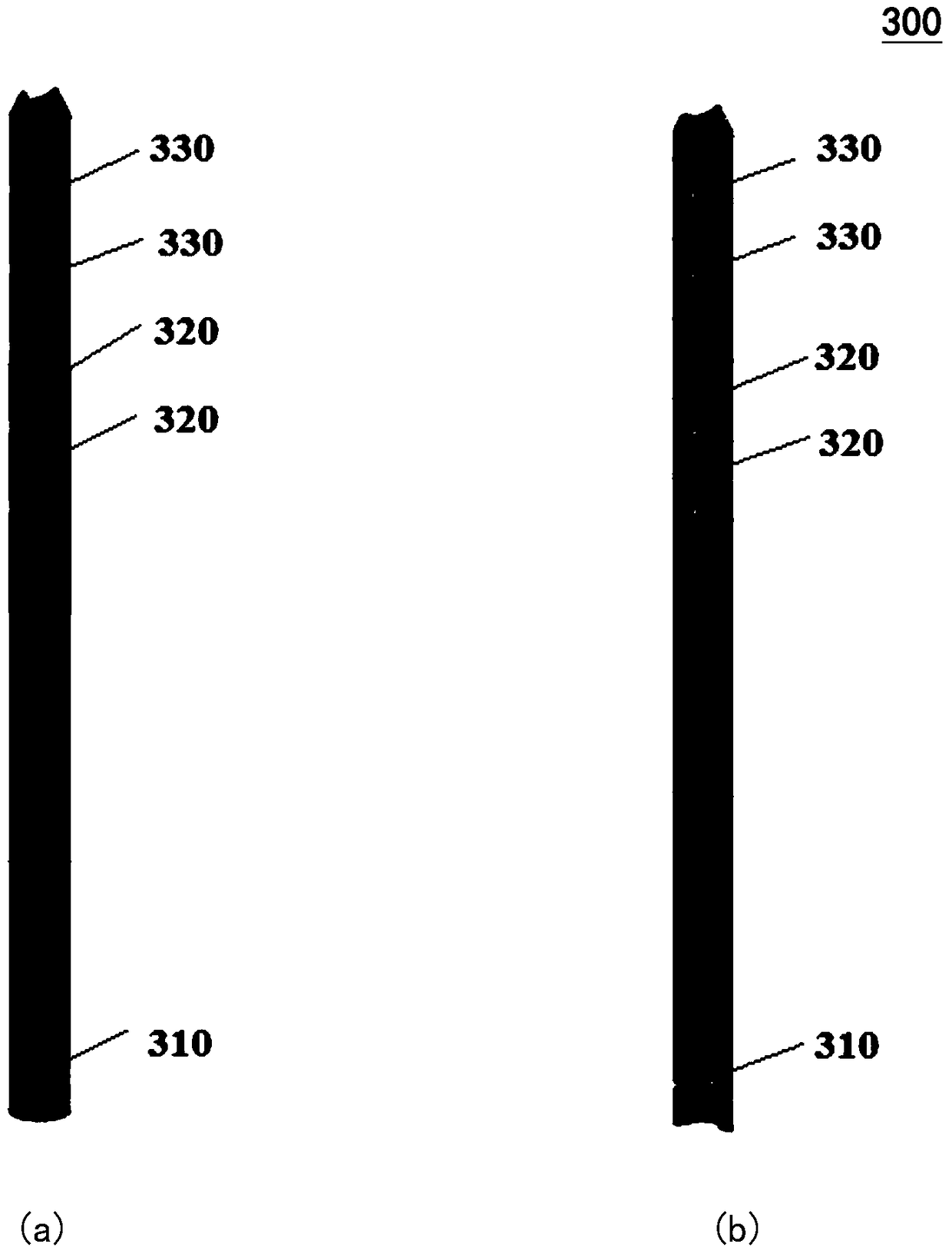

[0090] Figure 6 (a) shows a perspective view of a water / air shower nozzle according to one embodiment of the present invention; Figure 6 (b) shows a cross-sectional view of the water / air shower nozzle along the axial direction; Figure 6 (c) shows an enlarged partial cross-sectional view of the water / air shower nozzle, which shows a schematic diagram of water spraying from the pores. Specifically, the shower distributes mu...

Embodiment 3

[0091] Three, embodiment 3: acid steam cleaning device

[0092] Figure 7 A schematic diagram showing a more specific structure of an acid steam cleaner 3000 according to an embodiment of the present invention.

[0093] Such as Figure 7 As shown, the acid steam cleaning device 3000 includes an original acid solution container 1, a heater 2, a cleaning chamber 3, a plurality of acid steam, water, and gas ejection parts 4, a base 5, a water / air shower nozzle 6, and It includes a temperature sensor 7 , an integrated original acid level control component 8 , an upper casing frame 9 , a lower casing frame 11 , and an inlet port 12 .

[0094] The acid liquid temperature sensor 7 is placed inside the original acid liquid for measuring the temperature of the original acid liquid. The controller (not shown in the figure) sets the temperature threshold, receives the temperature measured by the acid temperature sensor 7, compares the temperature with the temperature threshold, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com