Diaphragm conveying device of accumulator packing machine

A technology of conveying device and wrapping machine, which is applied in the directions of transportation and packaging, winding strips, and thin material processing, etc., which can solve the problems of unfavorable pole group assembly and arrangement, reduced production efficiency, and low guiding precision, and achieves favorable results. Assembling and sorting, improving production efficiency, and improving the effect of conveying and guiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

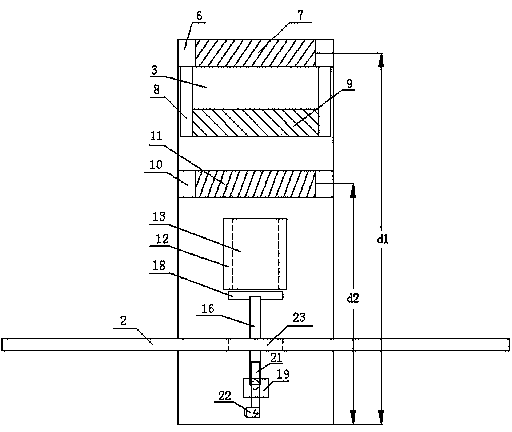

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] A diaphragm conveying device for a battery packer, comprising a support frame 1 and a transfer bed 2, wherein the support frame 1 is located on one side of the transfer bed 2, and the support frame 1 is composed of a vertical frame 3, a first horizontal frame 4 and a second horizontal frame frame 5, the first horizontal frame 4 is composed of two first support arms 6 arranged in parallel, one end of the first support arm 6 is vertically connected with the vertical frame 3, and the two first support arms 6 are arranged between There is a first film roller 7, and a connecting plate 8 is arranged on the two first supporting arms 6, and the connecting plate 8 is obliquely connected with the first supporting arm 6, and a second film is arranged between the connecting plates 8. Roller 9, the second horizontal frame 5 is composed of two seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com