Semi-automatic tool for mounting baffles of quartz watch movement coil

A semi-automatic and watch technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of high scrap rate and low efficiency of press-fitted baffles, and achieve the effect of improving the degree of automation and work efficiency, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

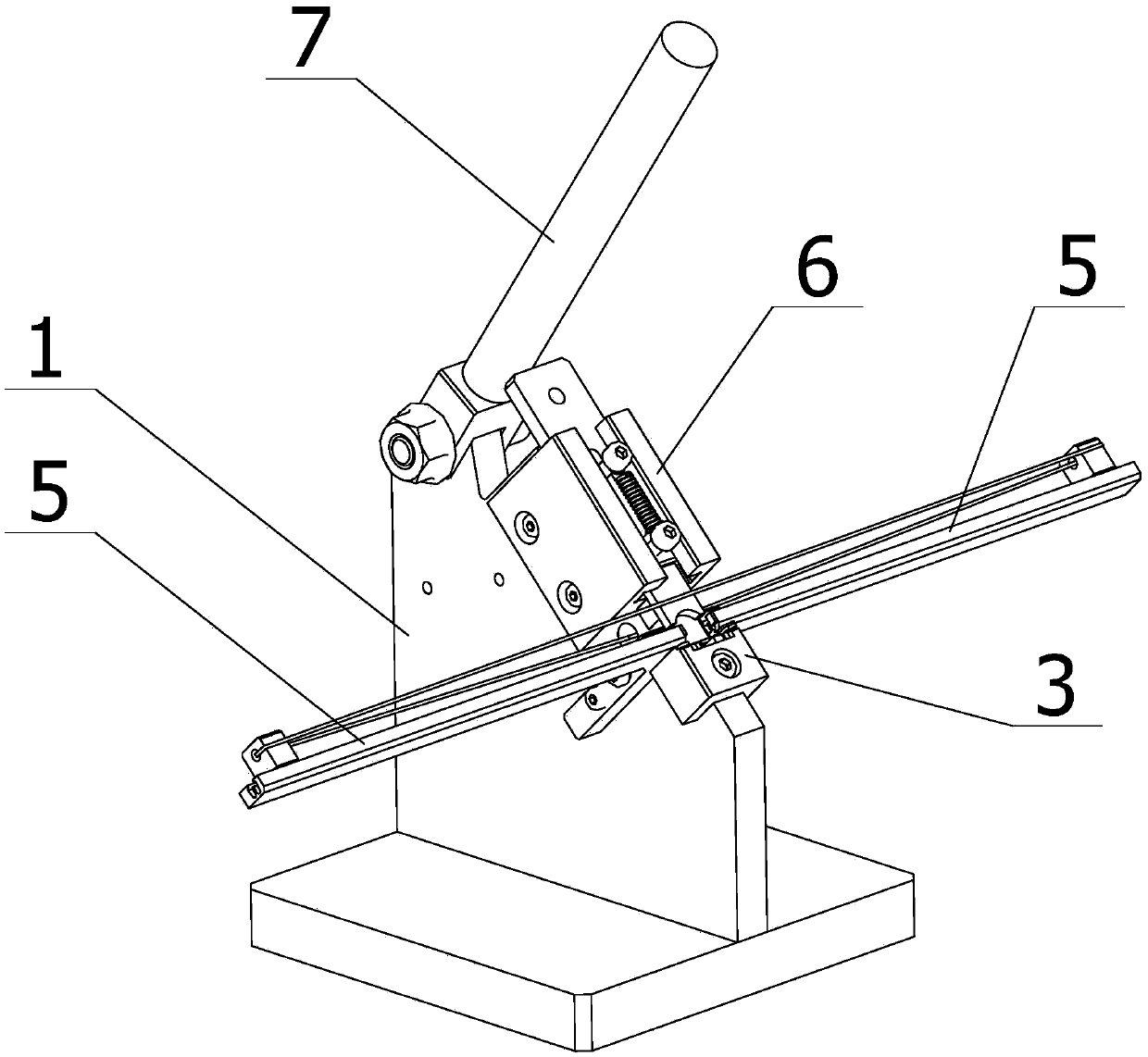

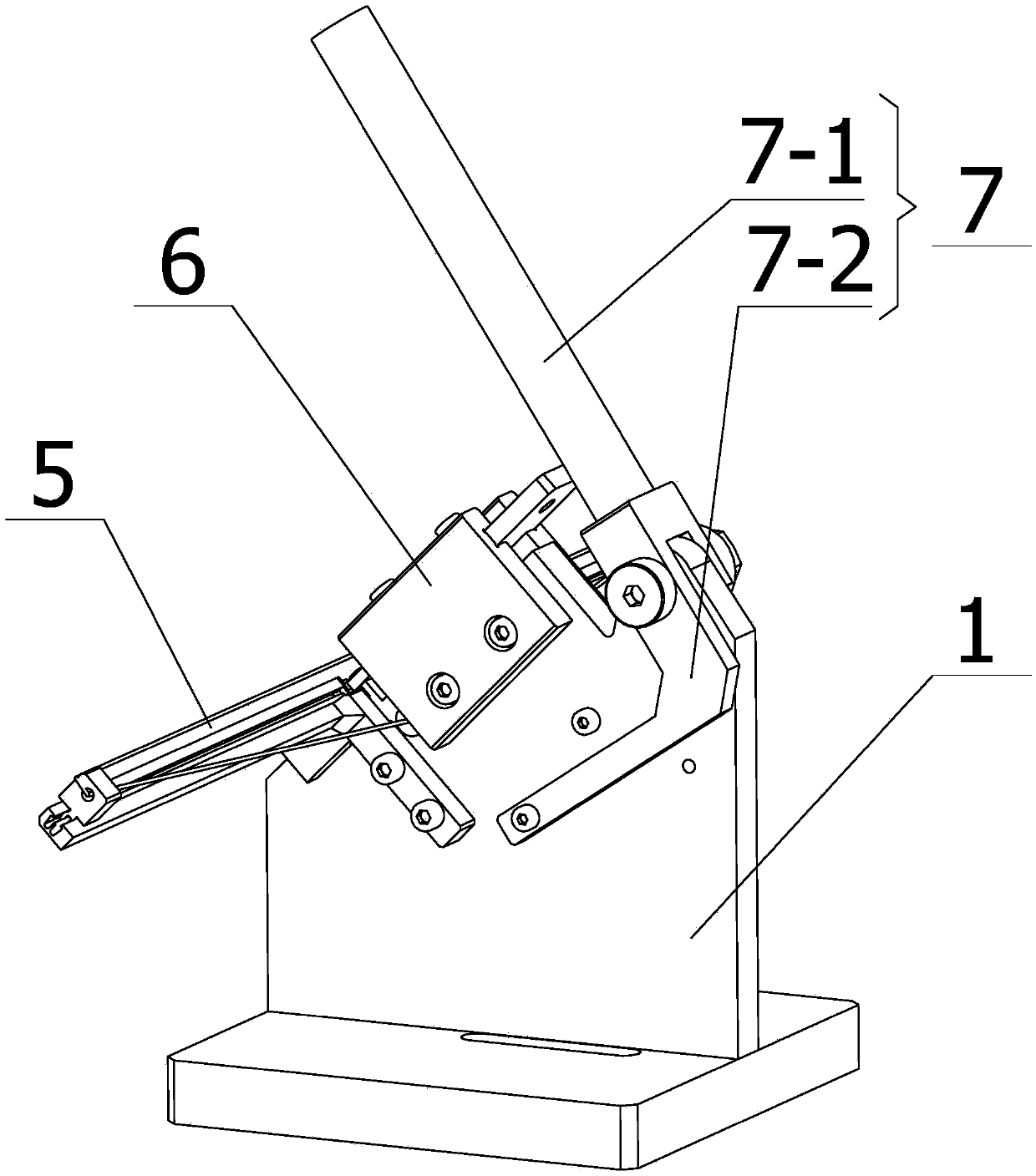

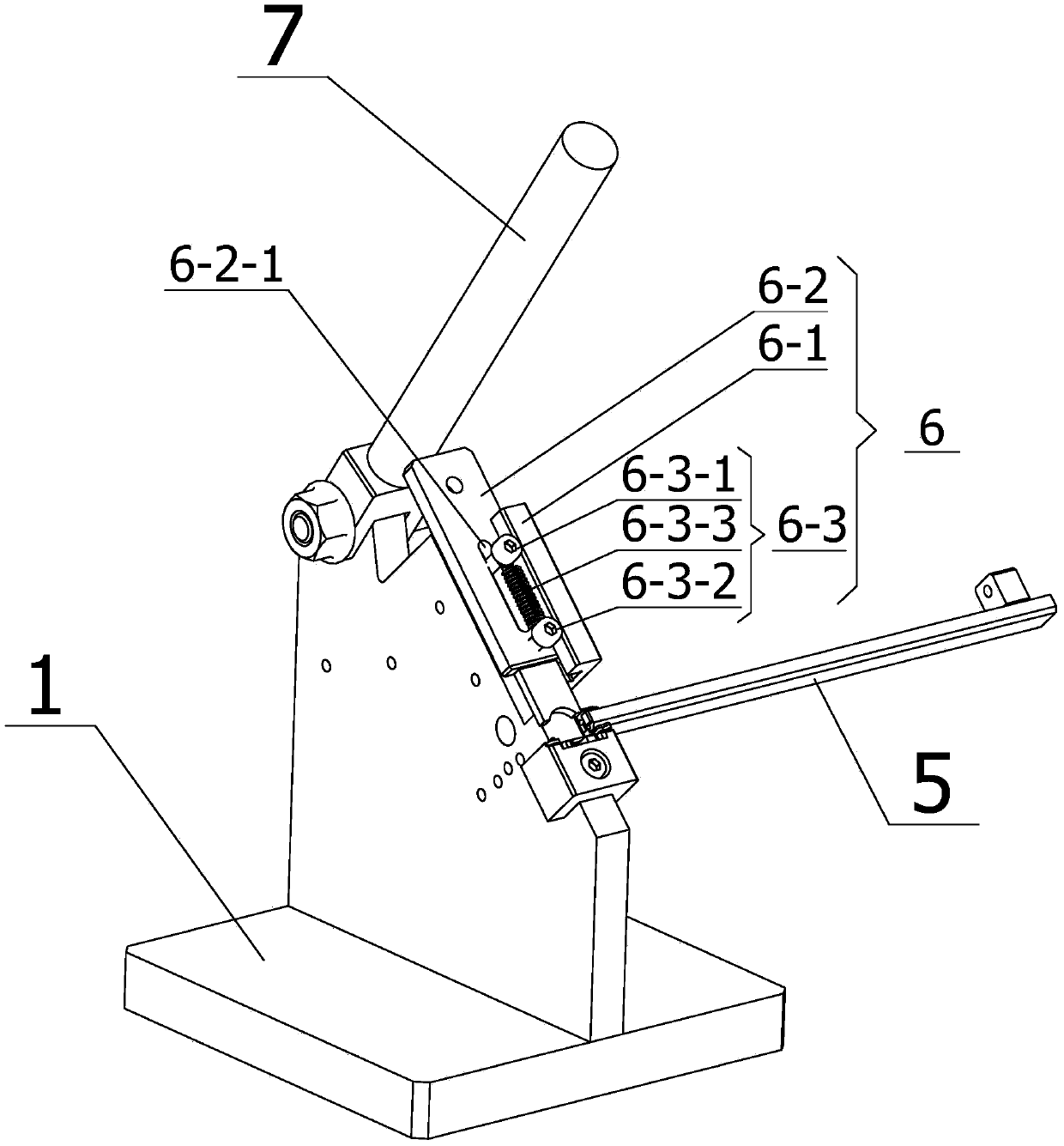

[0030] Such as figure 1 - Figure 10 As shown, a semi-automatic tooling for installing a bezel for a quartz watch movement coil provided by the present invention includes a base 1 and an iron core positioning seat 3 arranged on the base 1 for positioning the iron core 2 on the quartz watch movement coil , the baffle delivery device 5 that is symmetrically arranged on both sides of the iron core positioning seat 3 and is used to continuously transport the baffle 4 on the coil of the quartz watch movement to the iron core positioning seat 3, and the baffle conveying device 5 that is slidably arranged on the base 1 for conveying The baffle plate 4 above the core positioning seat 3 is press-fitted to the press-fit assembly 6 on the iron core 2 and the sliding drive device 7 provided on the base 1 for driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com