Working method of squeezer with cleaning barrel

A working method, a technology for cleaning the cylinder, applied in cleaning methods and utensils, chemical instruments and methods, household machinery for filtering food, etc., and can solve problems such as skin residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

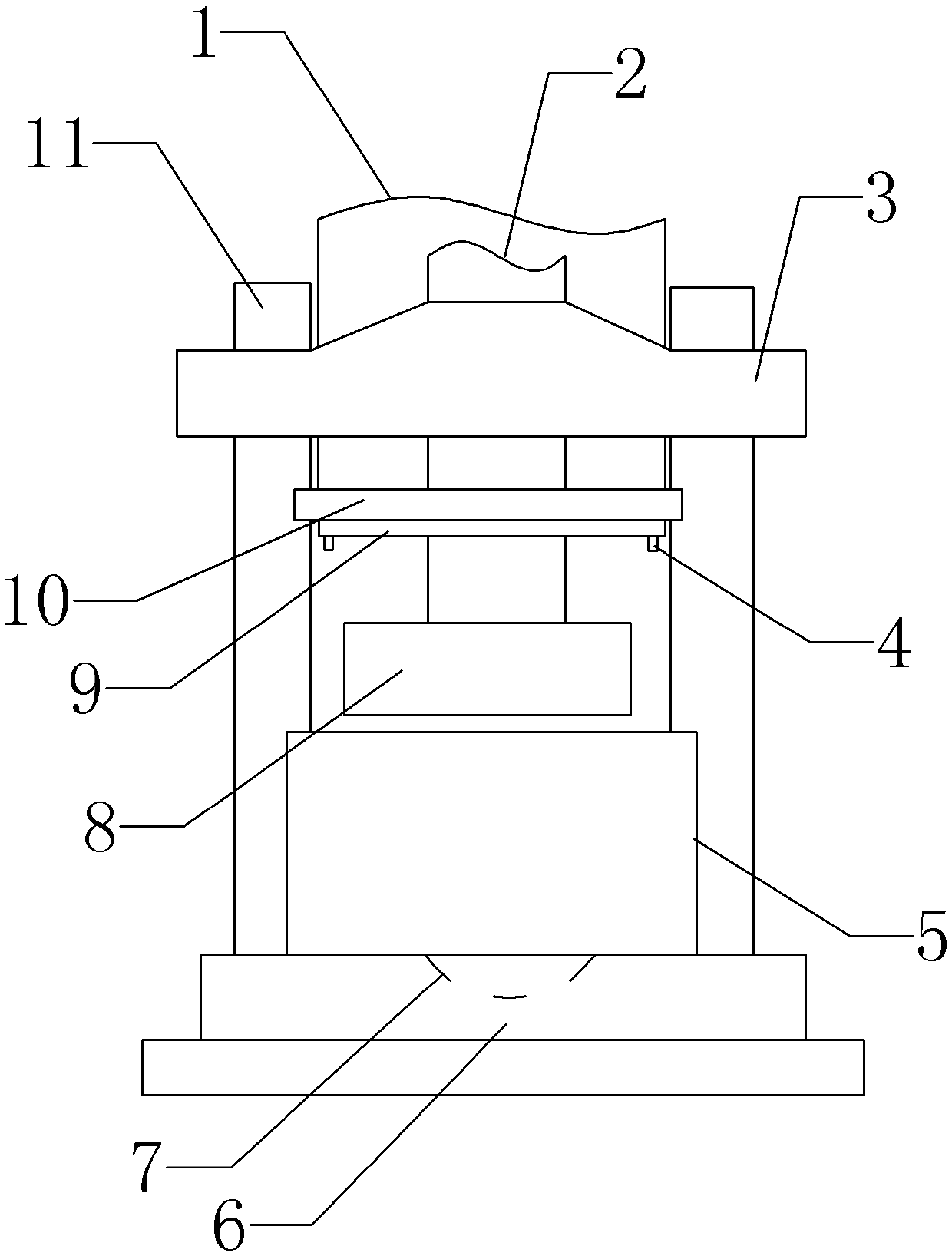

[0014] The reference signs in the drawings of the specification include: cleaning cylinder 1, pressing rod 2, mounting seat 3, bolt 4, containing cylinder 5, diversion flow groove 6, base 7, pressure plate 8, elastic clamp 9, annular guide plate 10, Column 11.

[0015] The embodiment is basically as attached figure 1 Shown: In this embodiment, there is a press machine with a cleaning cylinder, the base 7 is located on the upper part of the base, the upper part of the base 7 is provided with a container 5 that is open up and down, and the upper part of the base 7 is located in the container 5 and is provided with a flow guide groove 6. One side of the diversion flow groove 6 is connected to the juice outlet pipe, and a first valve is arranged at the juice outlet pipe. The other side of the diversion flow groove 6 is connected with the water outlet pipe, and a second valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com