Control method for improving low voltage ride through capability of wind power plant

A technology of low voltage ride-through and control method, which is applied in wind power generation, single grid parallel feeding arrangement, etc., can solve the problems of reducing fault recovery time, etc., so as to reduce fault recovery time, maintain stability, and reduce Crowbar action. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

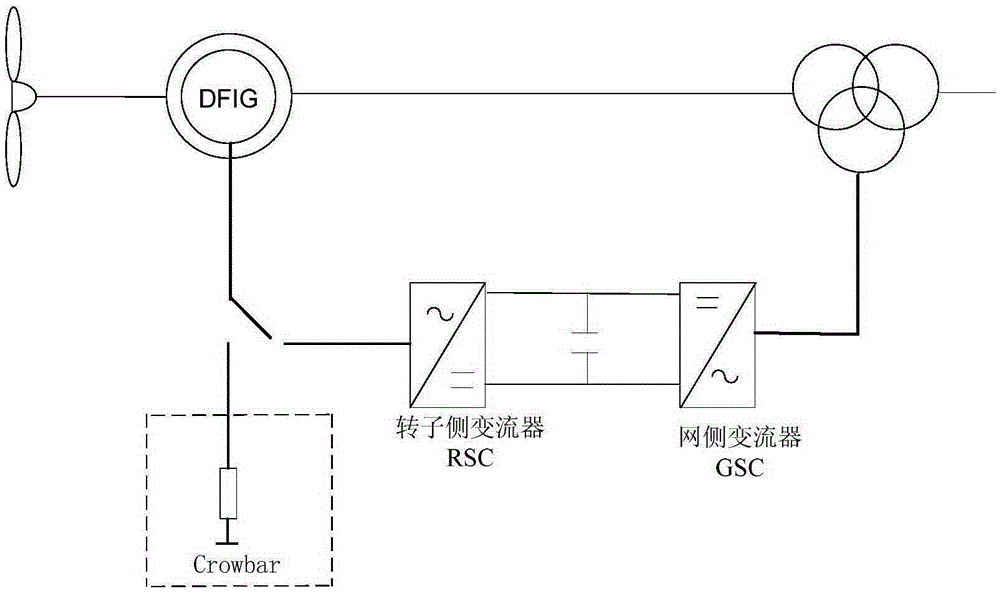

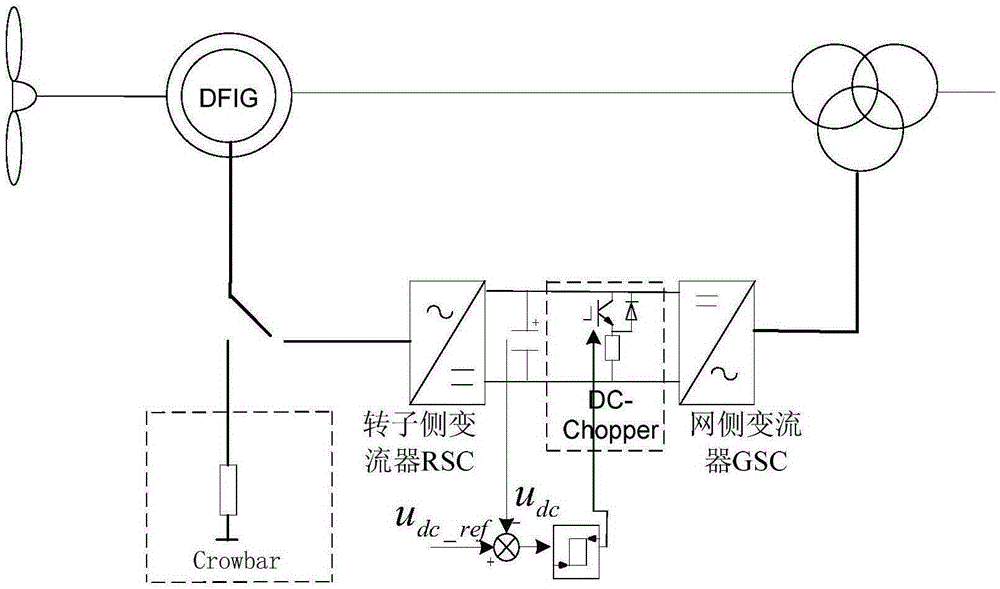

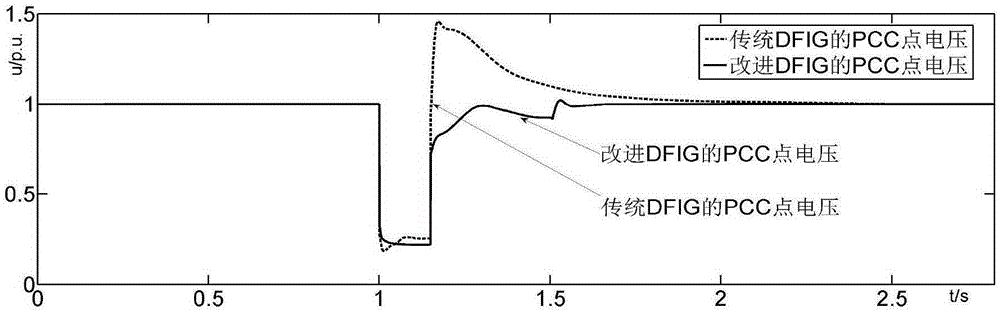

[0027] Traditional DFIG and improved DFIG models such as figure 1 , 2 shown. The purpose of the crowbar in traditional doubly-fed wind turbines is to protect the rotor-side converter RSC from being burned in case of failure. Although the rotor-side converter is protected, when the crowbar operates, the DFIG becomes a conventional asynchronous generator and needs to be absorbed from the grid. A large amount of reactive power, and sacrificed the reactive power support capability of the wind turbine when it fails. The improved DFIG uses active DC-Chopper with Crowbar to replace the traditional Crowbar protection technology, and controls the input of DC-Chopper switch according to the DC bus voltage. When the grid voltage drops, the output power of the grid-side converter GSC is limited, and the energy accumulates on the DC side, causing the DC bus voltage U dc When it reaches a certain value, the IGBT in the DC-Chopper circuit is triggered to turn on, and the unloading resisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com