A quasi-universal compensating mirror based on deformable mirror and its design method

A technology of deformable mirror and compensating mirror, applied in measurement devices, instruments, optical devices, etc., can solve problems such as nano-level free-form surface shape errors, and achieve the effects of reducing design difficulty, easy calibration and adjustment, and fewer error sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The specific parameters of the large-diameter free-form surface measured in this example are as follows:

[0035] Diameter: 110mm; Aspheric coefficient: -1.3; Vertex curvature radius: 500mm;

[0036] Additional Zernike higher-order terms for face shape: Z 4 = -8.2515; Z 5 = -9.789732; Z 9 = -1.271369;

[0037] The first-stage compensator obtained by the above design method is a single lens, and the parameters are as follows:

[0038] R 1 =167.25mm,R 2 =2899.68mm, thickness d=35.6mm, and the material is commonly used K9 glass.

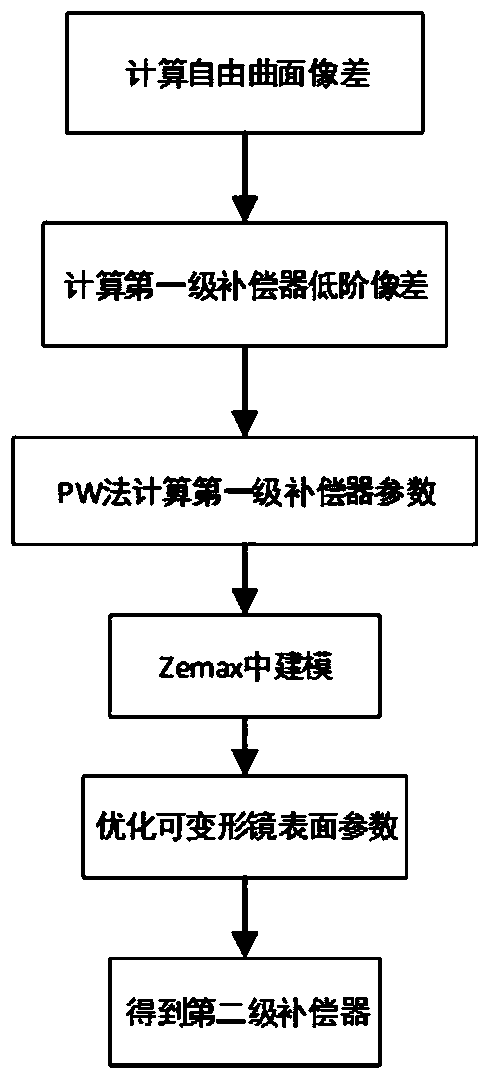

[0039] Add a deformable mirror, model the system in the optical design software Zemax, optimize the surface parameters of the deformable mirror, and finally get the surface type of the second-stage compensator (using the Zernike polynomial Z 4 -Z 29 Characterization):

[0040] Z 4 =-0.1453,Z 5 =0.08622,Z 6 =9.50E-4,Z 7 =-4.69E-3,Z 8 =1.65E-3,Z 9 =0.0379,Z 10 =3.13E-3,Z 11 =0.0448,Z 12 =0.0155,Z 13 =7.51E-4,Z 14 =-2.12E-3,Z 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com