Accurate assembly method and improved structure of air compressor motor plate and static plate plane gap

A technology of air compressors and moving discs, which is applied to machines/engines, parts of pumping devices for elastic fluids, and pump parts of rotary piston type/oscillating piston type, etc., which can solve the problem of increasing the difficulty of processing parts and increasing the Manufacturing costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

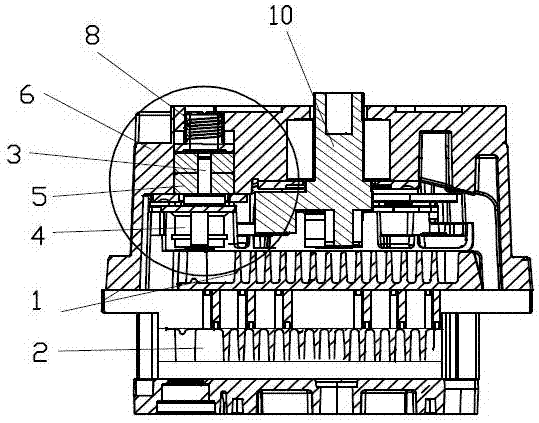

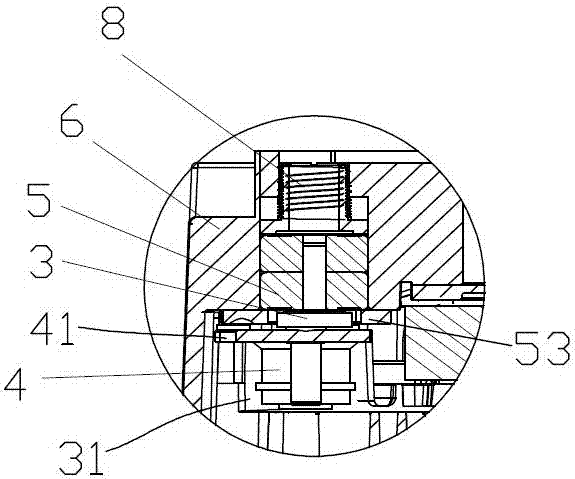

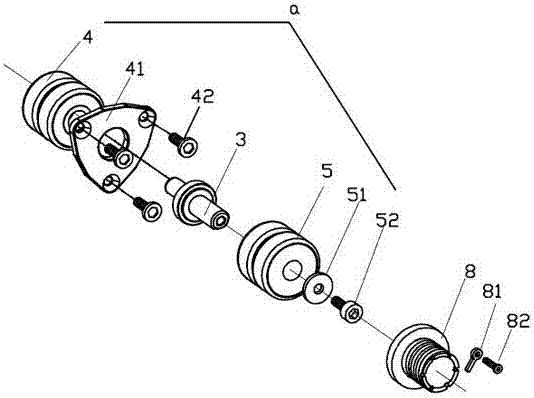

[0016] Such as Figure 1-6 As shown, the precise assembly method for the plane gap between the moving disc and the static disc in the air compressor includes the moving disc 1, the static disc 2, and the standard thickness sheet for adjusting the plane gap between the two. The following steps are used to realize the assembly operation: first Combine ① small eccentric shaft 3, screw 31, moving plate bearing 4, moving plate bearing pressure plate 41, base bearing 5, gasket 51, and fastening screw 52 to form the first component a② and then set the adjusting screw 8 on the casing In the mounting hole on the base 6, the adjusting screw 8 is threadedly connected to the bottom of the base, the first component a is then installed into the mounting hole, and the bottom of the adjusting screw 8 bears against the base bearing 5; The base 6 is combined and assembled to form the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com