A fast installation tool for LED light strip light source

A technology of LED light strips and light sources, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of low installation efficiency, and achieve the effects of improving efficiency, economical and practical, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

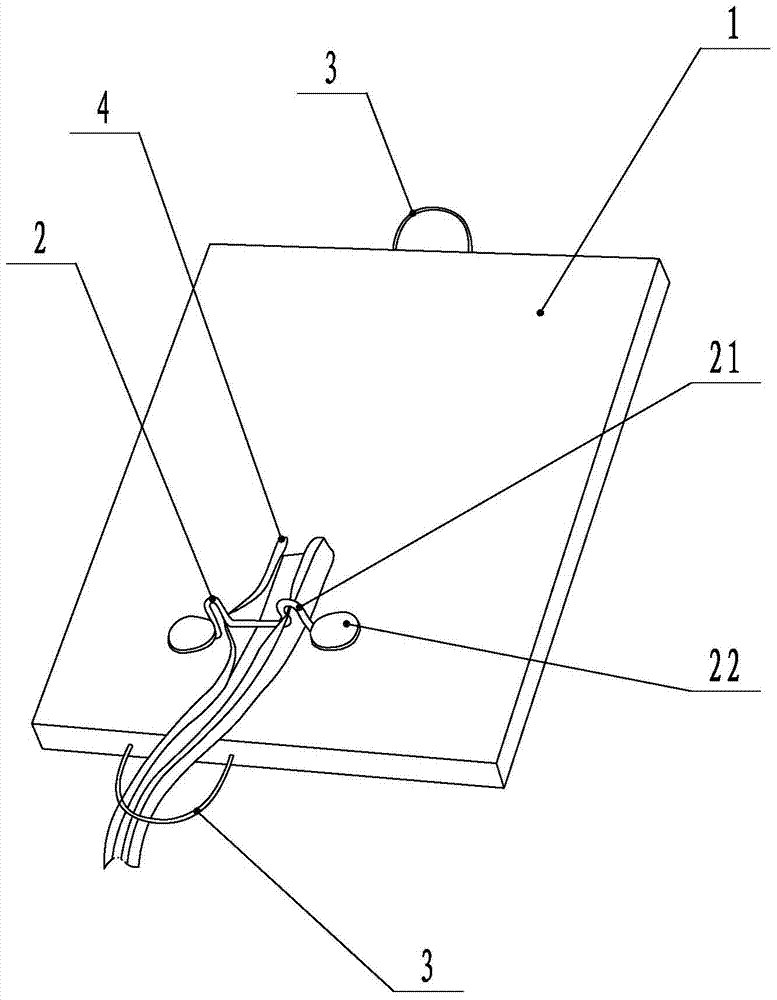

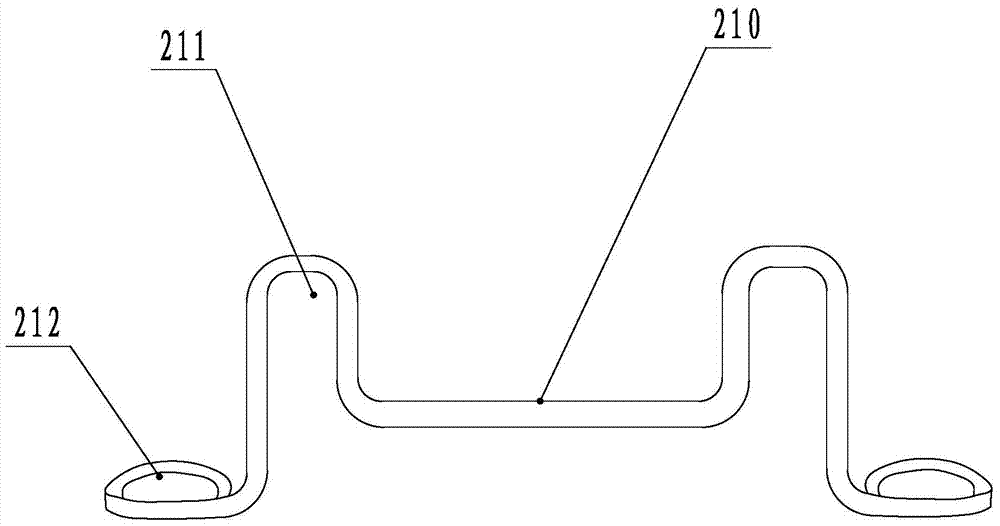

[0015] refer to figure 1 and figure 2 , a LED light strip light source quick installation tool of the present invention, including a base 1 and a spreader 2 installed on the base 1, the spreader 2 includes a spreader 21 and a fixing device 22, the shape of the spreader 21 Compatible with the inner cavity of the wick film cover 4 used to install the light source of the LED light strip, the expansion bracket 21 is fixed and installed on the base 1 through the fixing device 22, and the wick film cover 4 is inserted into the expansion support 21 during installation. The opening of the wick film cover 4 can be opened, so that the light source can be inserted into the wick film cover 4 conveniently and quickly, thereby greatly improving the efficiency of installation. Meanwhile, the tooling is simple in structure, economical and practical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com