Magnetic operation control apparatus

A technology of operation control and magnetic force, which is applied in the field of magnetic force operation control equipment, can solve problems such as noise, vibration, inability to adjust the operation process, and difficulty in accurately controlling the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

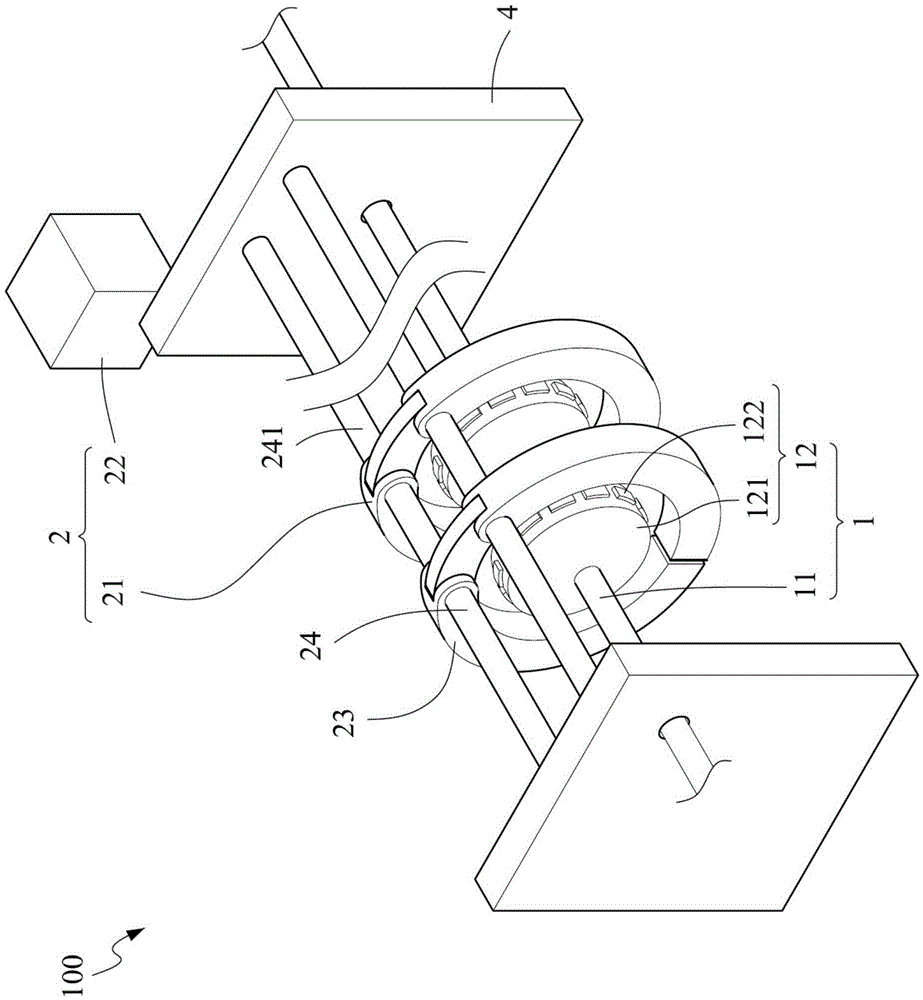

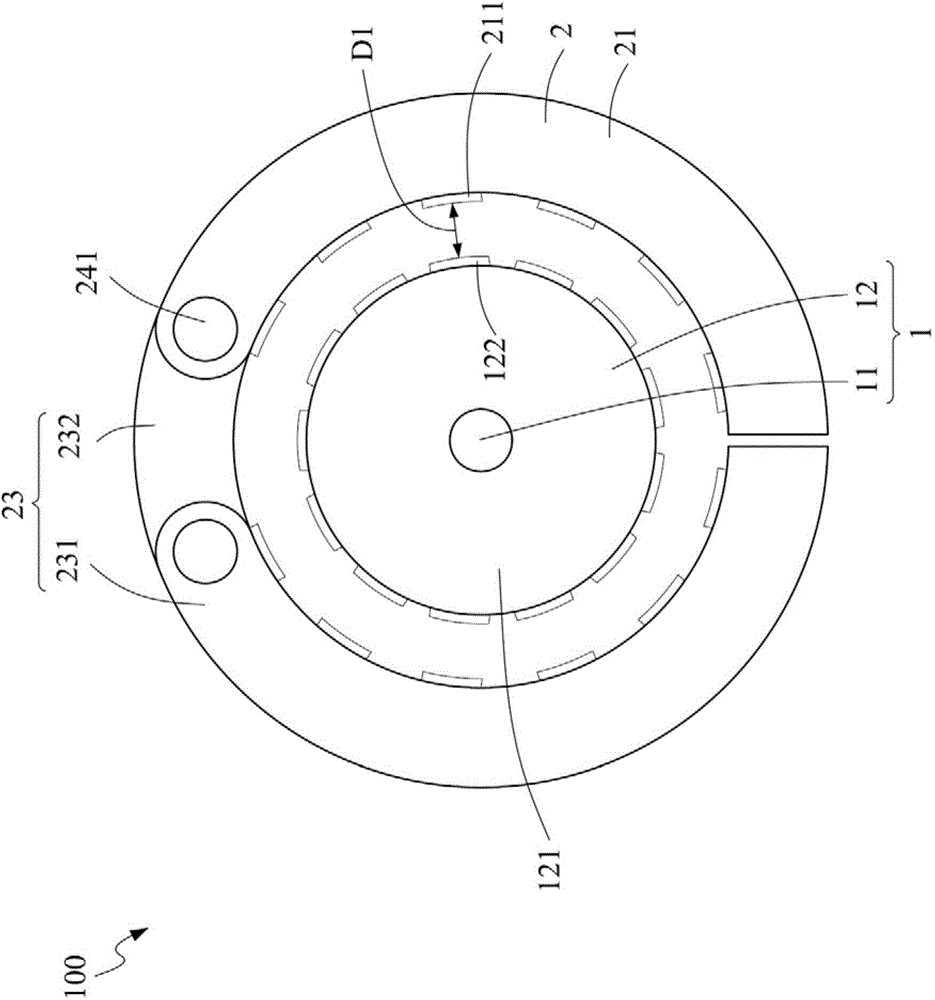

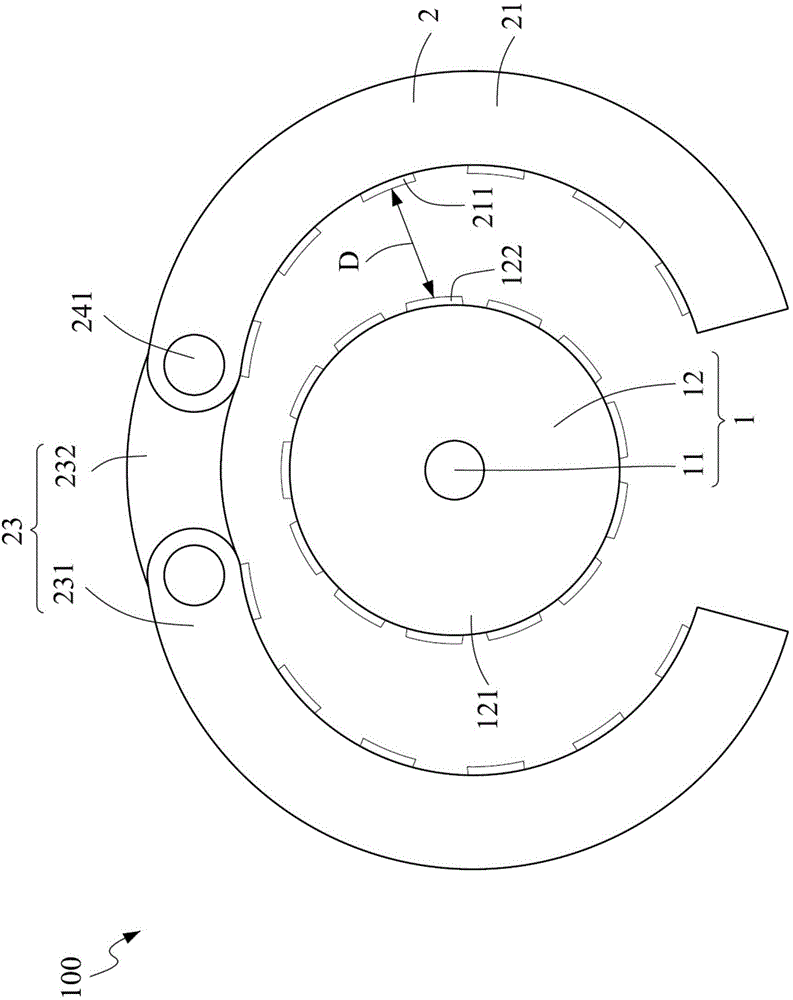

[0044] The specific embodiments adopted by the present invention will be further described through the following embodiments and attached drawings.

[0045] based on the following Figure 1 to Figure 8 , and the embodiment of the present invention will be described. This description is not intended to limit the embodiment of the present invention, but is one of examples of the present invention.

[0046] Such as Figure 1 to Figure 8 As shown, a magnetic force operation control device 100 according to an embodiment of the present invention includes: a transmission device 1, including a transmission shaft 11 and four rotating mechanisms 12, 12a, 12b, 12c arranged on the transmission shaft 11, Each rotating mechanism 12, 12a, 12b, 12c includes at least one rotating wheel 121 and several magnetic members 122 annularly arranged at the outer periphery of the rotating wheel 121; and a driving force device 2, including four groups of driving force mechanisms 21, 21a . 21c has at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com