Turbine rear force bearing case integrally connected to rectification blade cascade

A technology of load-bearing casing and rectifying blade cascade is applied in the field of aviation propulsion to achieve the effects of reducing weight, increasing thrust-to-weight ratio, and shortening axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

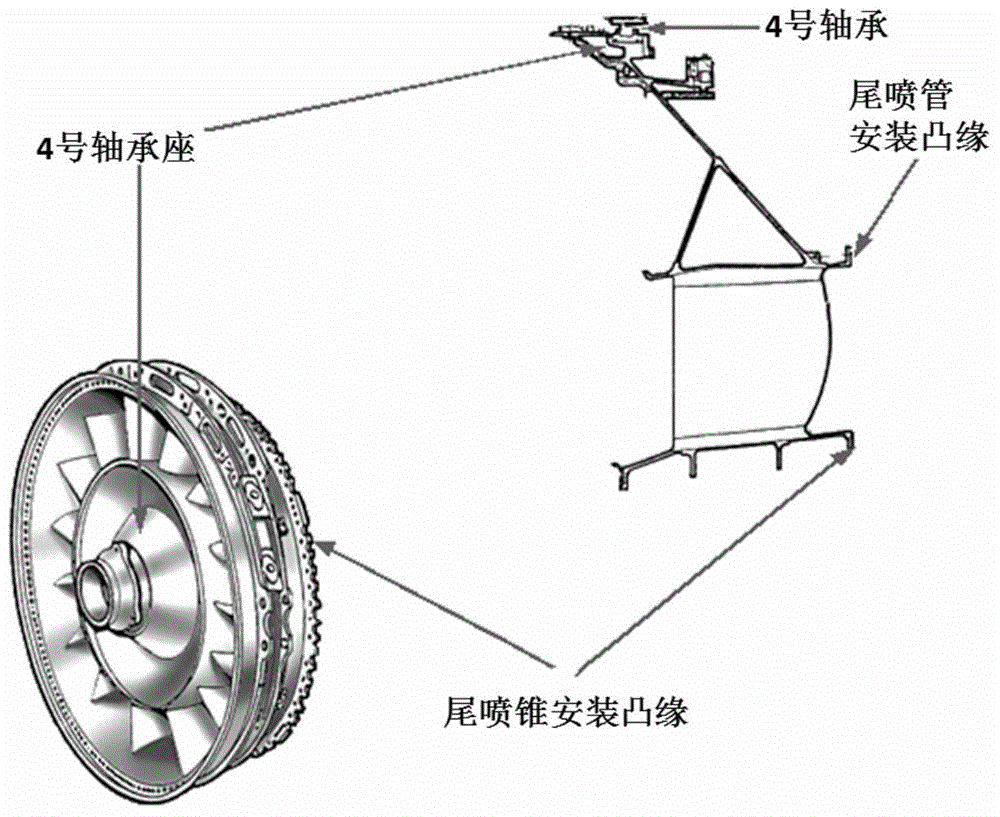

[0027] The present invention provides an integrated connection structure between the turbine rear bearing casing and the rectifying blade cascade. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

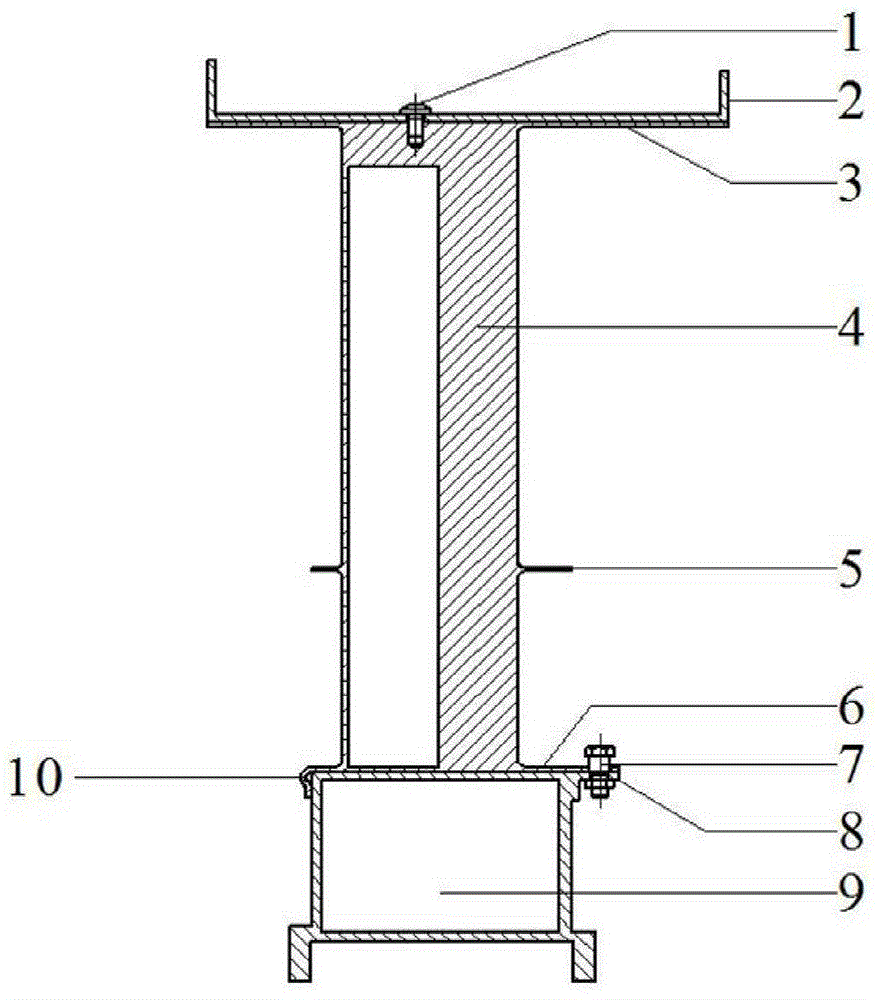

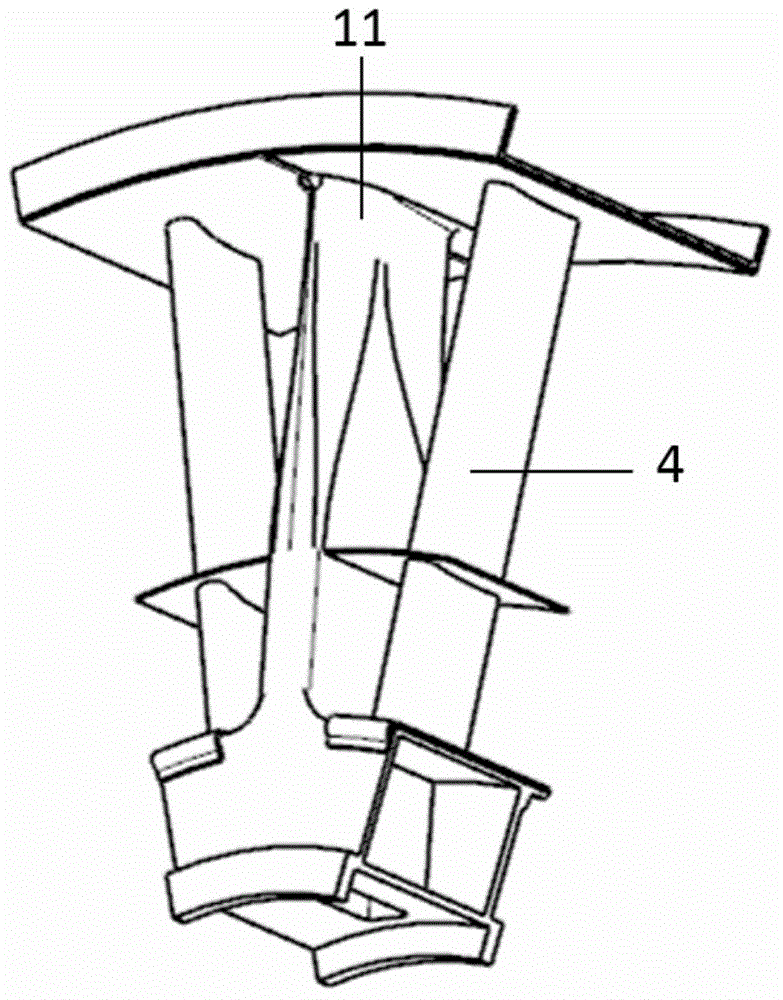

[0028] Such as figure 2 and image 3 As shown, in the integrated connection structure of the turbine rear bearing casing and the rectifying blade cascade according to an embodiment of the present invention, in addition to the rear bearing casing outer ring 2 included in the existing turbine rear bearing casing structure 1. In addition to the inner ring 9 of the rear load-bearing casing and the load-bearing support plate 11, the blades 4 are discretely installed between each load-bearing support plate 11 along the circumferential direction. The cascade structure includes the blade upper edge plate 3, the blade 4, Blade runner 5 and blade lower edge plate 6 .

[0029] Open threaded holes at the upper edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com