Equipment for duplex printing

A technology of double-sided printing and front-side printing, used in printing, printing machines, general parts of printing machinery, etc., to prevent ink splitting and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

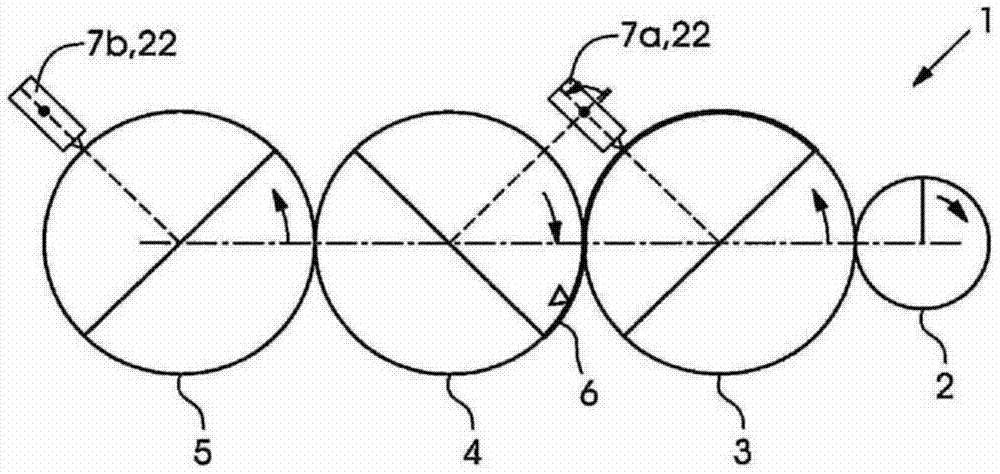

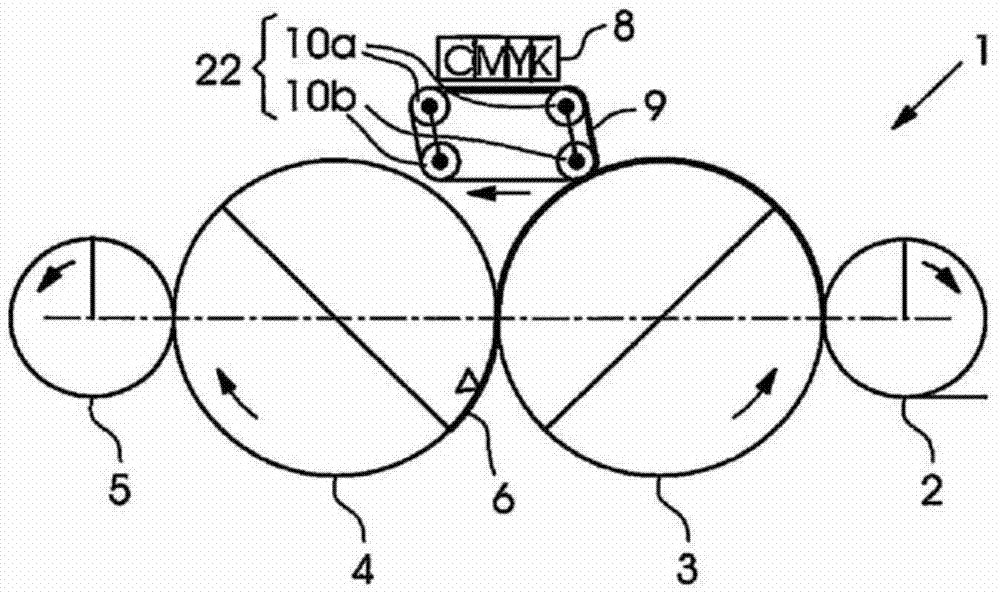

[0019] Figure 1a A partial view of a printing press 1 is shown, which comprises a transport cylinder 2 and at least two (counter-press) impression cylinders 3 , 4 , 5 . The second impression cylinder 4 is designed here as a cylinder which guides the sheet over 360°. Furthermore, the partial illustration shows two printing heads 7a, 7b in the form of inkjet printing heads, wherein the first inkjet printing head 7 can be pivoted between the first impression cylinder 3 and the second impression cylinder 4 . Furthermore, the sheet 6 that has undergone the printing process can be seen. The sheet 6 is printed on the first impression cylinder 3 by the first inkjet print head 7 a on the front sheet and delivered to the second impression cylinder 4 . The printed front sheet of the sheet 6 now faces inwards on the second impression cylinder 4 .

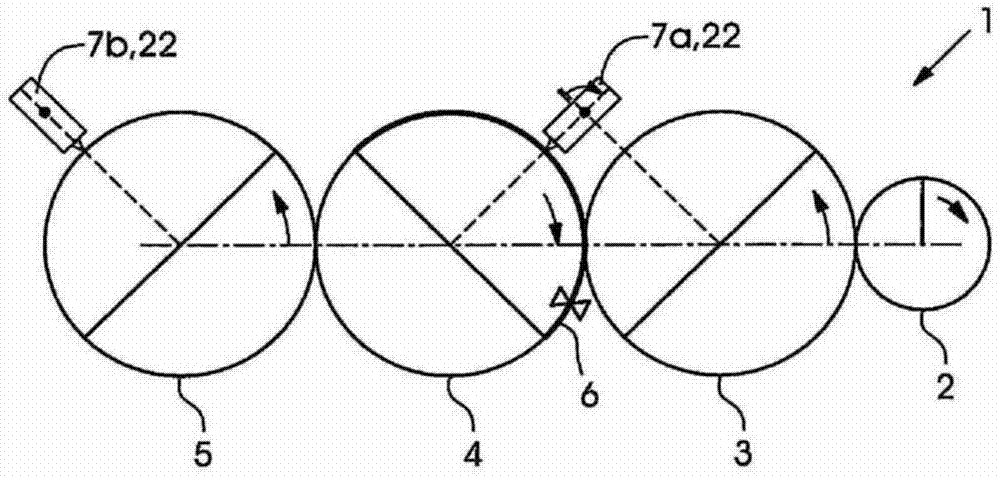

[0020] Figure 1b shown with Figure 1a The same partial view of the printing machine 1 described in . In this case, the second impres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com