A kind of box girder web reinforcement positioning device and construction method thereof

A web reinforcement and positioning device technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of fast hoisting of reinforcement cages, poor overall stability, cumbersome disassembly of reinforcement, etc., to achieve fast construction speed, good reinforcement load, The effect of uniform bar spacing standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

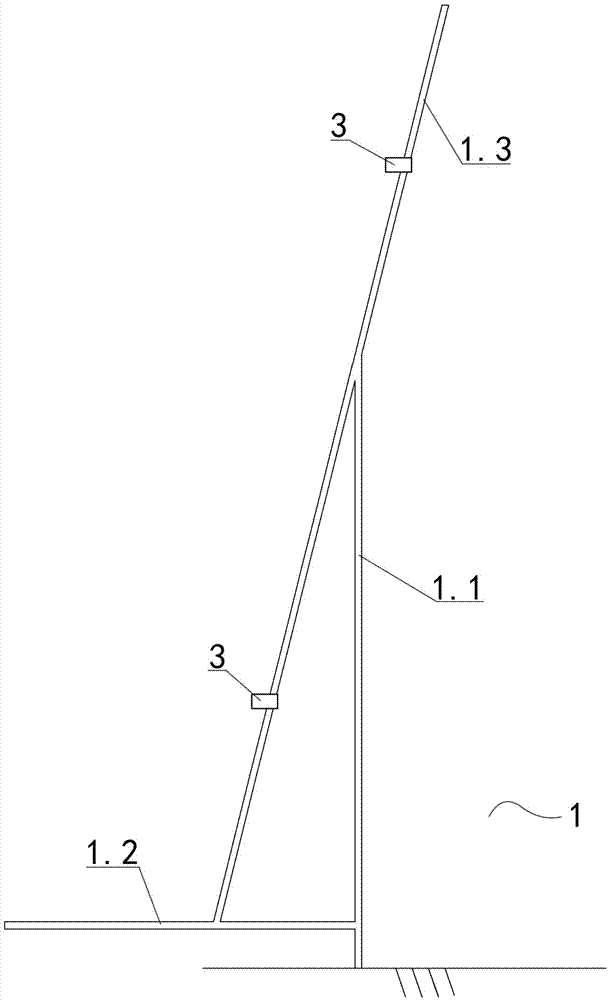

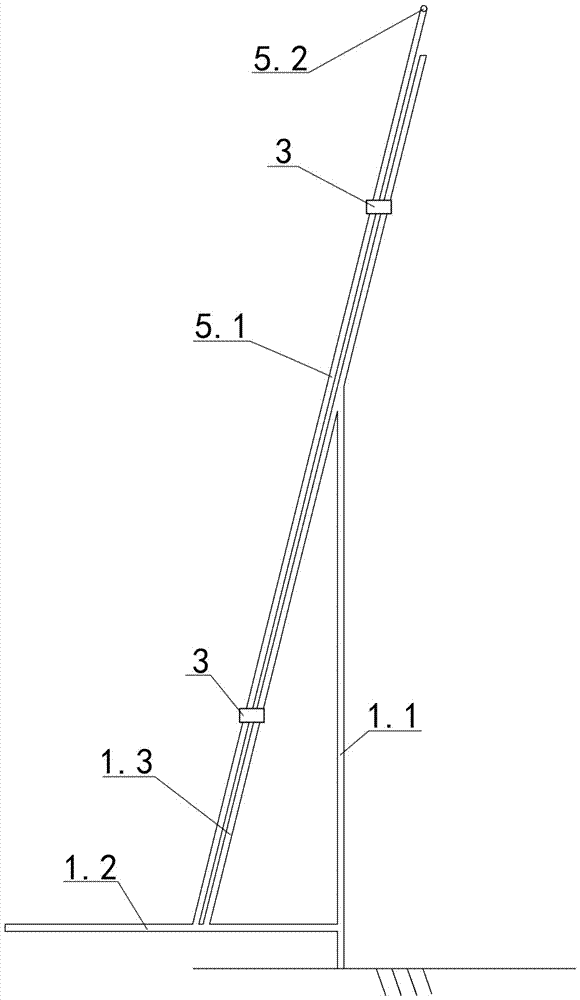

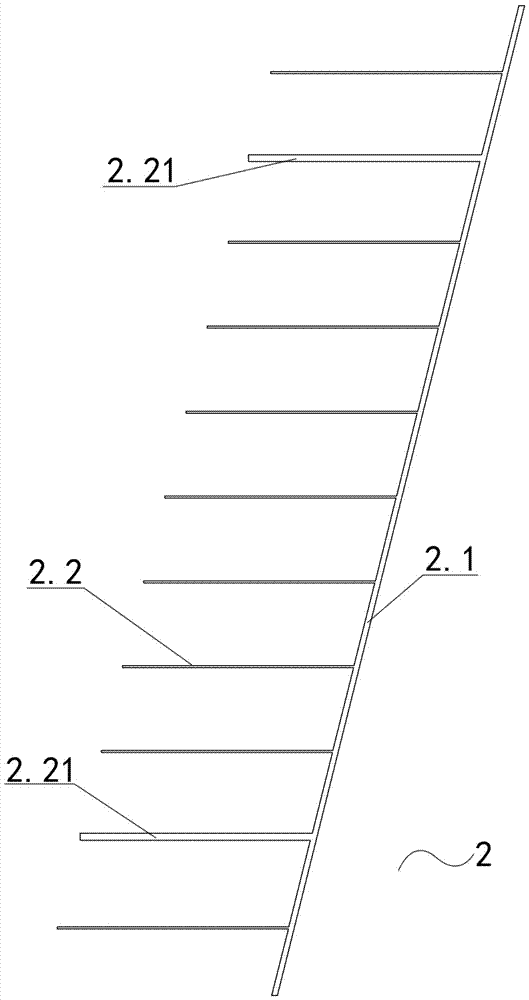

[0037] Examples see Figure 1-5 As shown, the direction along the beam is A, and the direction of the beam is B. A box girder web reinforcing bar positioning device, comprising a support positioning frame, the supporting positioning frame includes a floor support frame 1 placed outside the box girder web steel bar 4 in the direction of the beam and a reinforcing bar binding positioning frame 2 in the direction of the beam, The floor support frame is provided with a group at intervals along the beam direction, and one side of the floor support frame 1 is connected with at least one limit sleeve 3 with an opening level and facing the beam direction, and the side floor support frame is also connected with a suspended The steel bar binding positioning frame 2, the steel bar binding positioning frame is a comb-shaped frame body, and the comb-shaped frame body is composed of a comb back bar 2.1 and a group of comb-shaped steel bar binding support bars horizontally connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com