A high-precision segmental pulse generation method for temperature control

A technology of pulse generation and temperature control, which is applied in the direction of electric pulse generator circuit, etc., can solve the problems of temperature control fluctuations, too fast and difficult heating plate temperature rise, achieve uniform segmental heating, improve control accuracy, and reduce violent fluctuating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

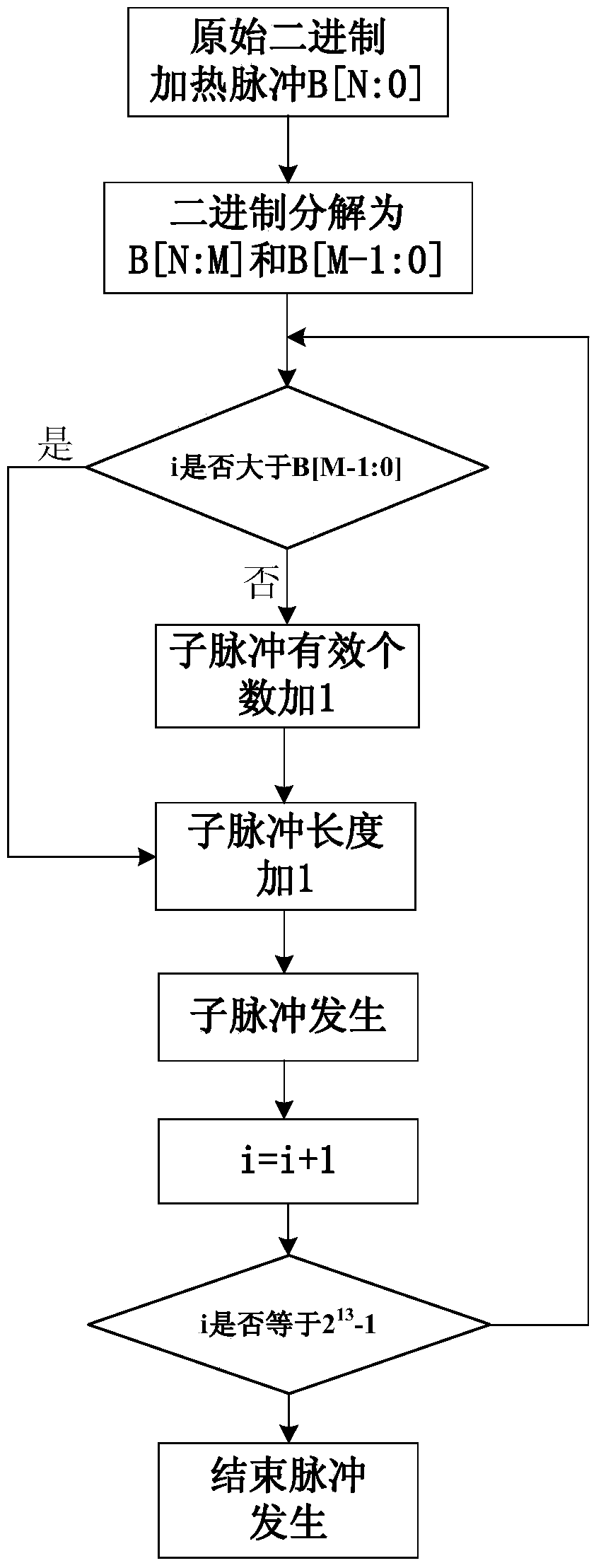

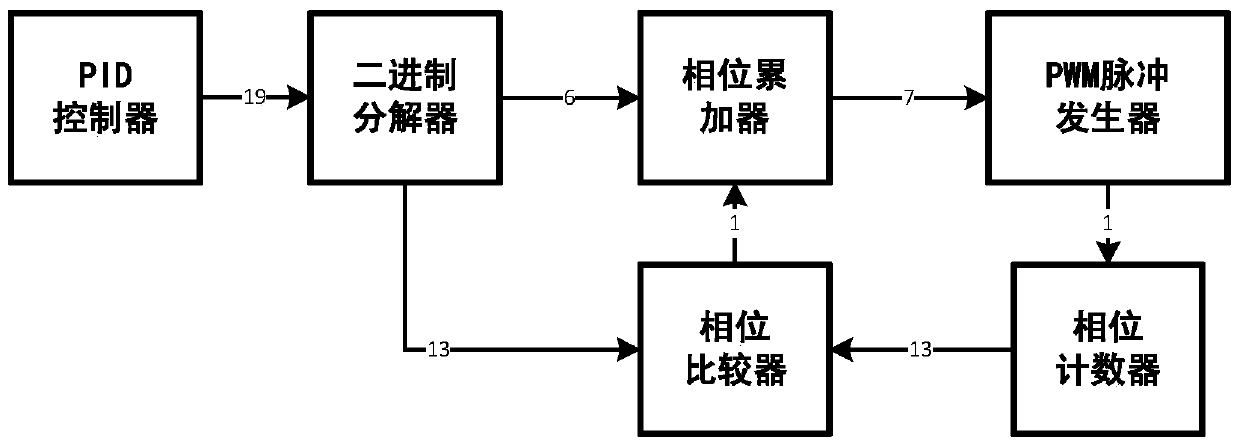

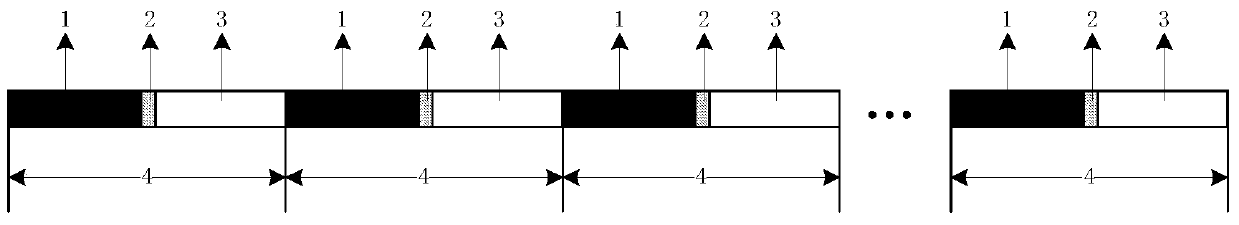

[0026] The present invention proposes a high-precision segmental pulse generation method for temperature control, using segmental heating instead of centralized heating, and forming a closed-loop control through a binary decomposition algorithm to ensure that the accuracy is not lost after segmenting. The following will be described in detail with reference to the accompanying drawings . Such as figure 1 , figure 2 Shown, working process of the present invention comprises:

[0027] Step (1), the PID controller outputs an original binary number pulse whose number of effective heating pulses is B[N-1:0] and enters the binary resolver, wherein the total length of the original binary number pulse is 2 N -1, the effective heating pulse in the binary number pulse is logic 1, and the remaining pulses are logic 0; the effective heating pulse is used to realize temperature control;

[0028] Step (2), the binary decomposer will decompose the effective heating pulse in the original b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com