Servo control system for simulating air pressure of aircraft

A servo control system and aircraft technology, applied in the field of servo control systems, can solve problems such as slow response speed, pressure shock, adjustment error, etc., to avoid shock and oscillation, respond quickly, and increase the degree of freedom of system control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

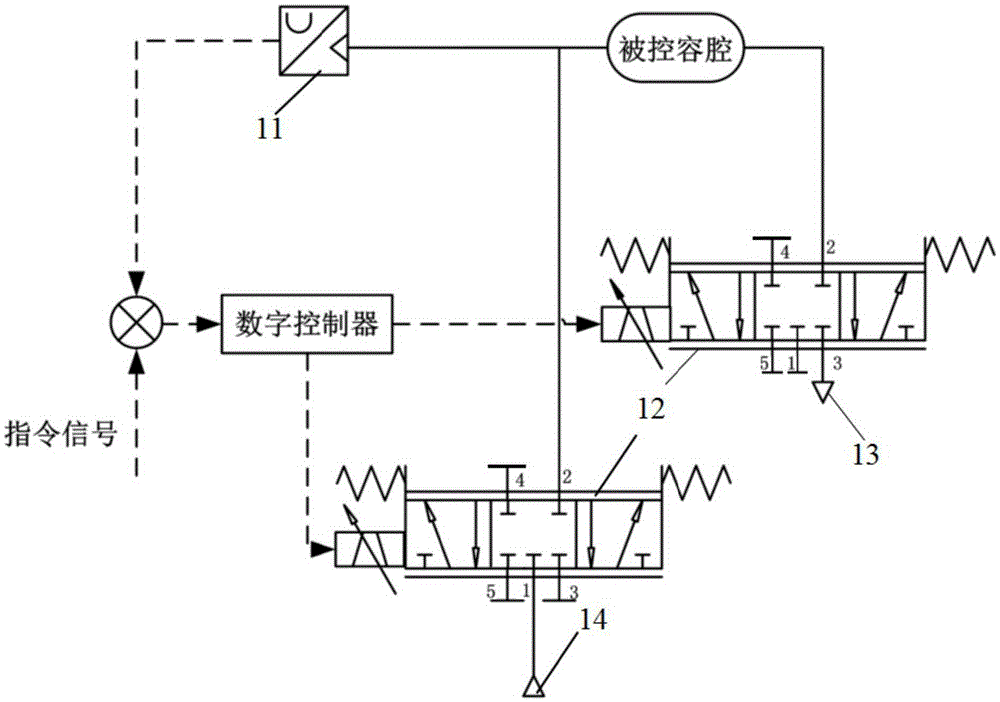

[0035] The servo control system includes a positive pressure source 14, a negative pressure source 13, a controlled cavity, a high-precision pressure sensor 11, a two-way electric-pneumatic proportional / servo valve 12, a digital controller, a D / A converter and an A / D converter, the digital controller is connected with the electric-pneumatic proportional / servo valve 12 through the D / A converter, and is used to control the switching state of the electric-pneumatic proportional / servo valve 13, the positive pressure source 14 and the The negative pressure source 13 is respectively connected to the controlled chamber through two electric-pneumatic proportional / servo valves 12, so that the air pressure of the controlled chamber is increased or decreased, and the controlled chamber and the digital controller are sequentially connected to each other. Connected with a high-precision pressure sensor 11 and an A / D converter, the high-precision pressure sensor 11 is used to detect the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com