A combined shock-isolation bearing of curved surface hinge sliding friction-roller rolling friction

A combination of seismic isolation bearings and sliding friction technology, which is applied in the direction of earthquake prevention, bridge parts, bridges, etc., can solve the problems of low horizontal yield force and increase horizontal yield force of rolling friction bearings, so as to reduce the seismic response of structures and extend the The effect of structural cycle and large energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

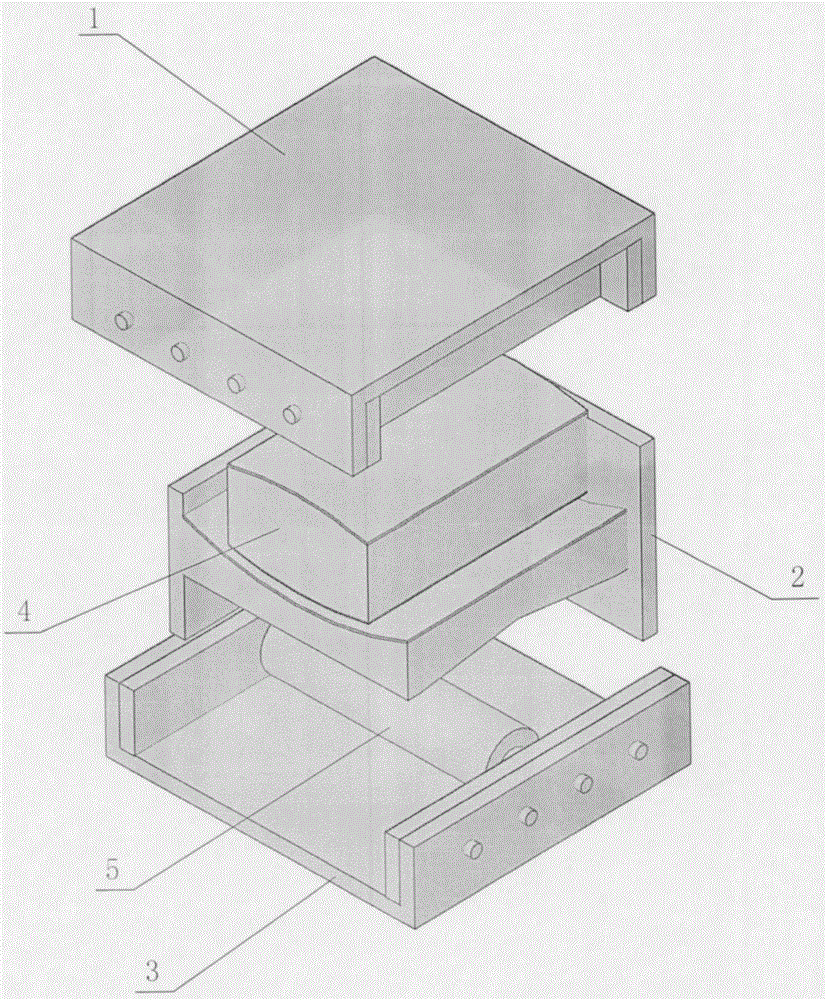

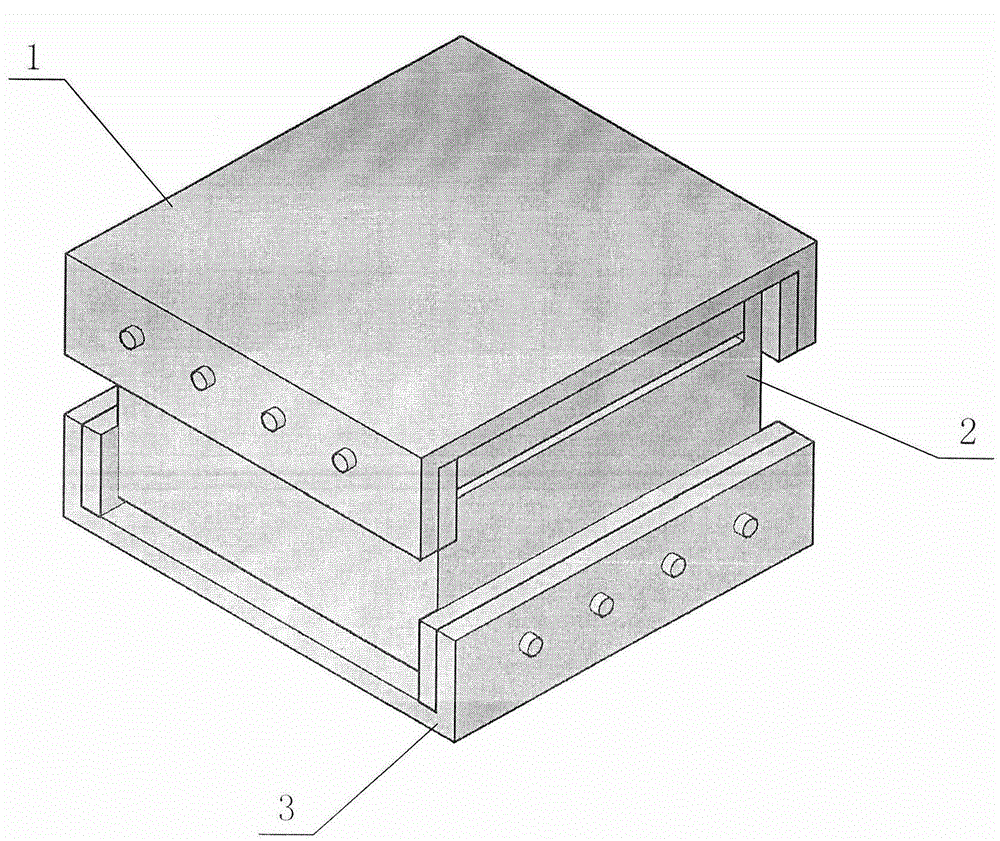

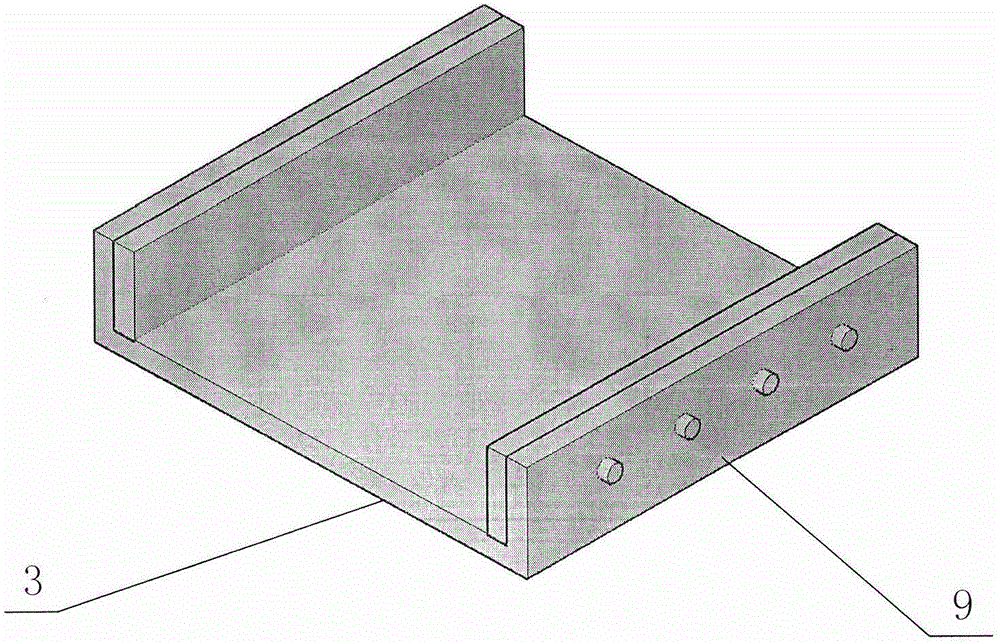

[0033] like figure 2 As shown, a curved surface hinge sliding friction-roller rolling friction combined vibration isolation bearing includes an upper bearing plate 1, a middle sliding plate 2, a lower bearing plate 3, and is placed between the upper bearing plate and the middle sliding plate The slider 4 and the roller 5 placed between the middle sliding plate and the lower bearing plate; as figure 2 , Figure 11 As shown, the upper surface of the upper support plate 1 is flat, and the lower surface is concave, the two ends of the concave surface are provided with upper support plate longitudinal stoppers 6, and the two sides of the concave surface are provided with upper support plate Lateral block group 7; as figure 2 , Figure 8 and Figure 9 As shown, the middle sliding plate 2 is located between the upper support plate 1 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com