Synthetic method of poly-alpha-olefin lubricating oil with oxidation resistance

A technology of olefin lubricating oil and anti-oxidation performance, which is applied in the direction of lubricating composition, petroleum industry, base material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

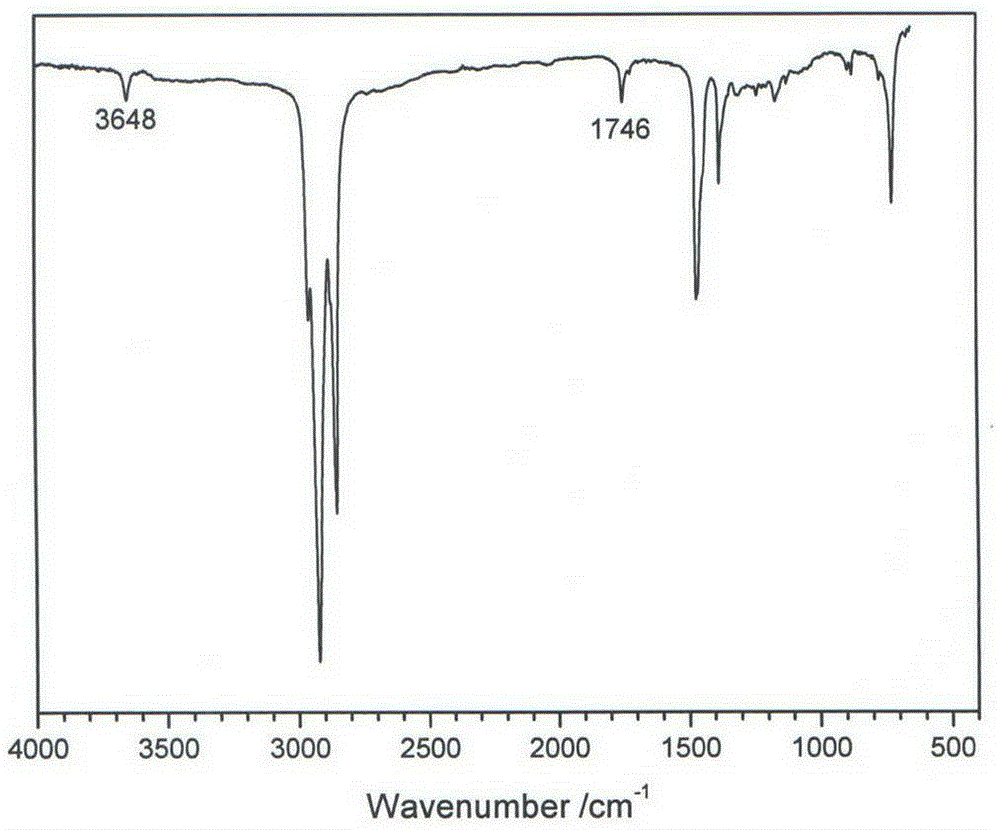

Image

Examples

Embodiment 1

[0016] Weigh 11.8g of hexanediol and 27.8g of β-3,5-di-tert-butyl-4-hydroxyphenylpropionic acid into a 250mL three-neck flask reaction device equipped with electric stirring, thermometer, water separator and condenser, and add the catalyst The mass fraction is 0.3% stannous chloride, and then 70 mL of xylene is added as a solvent, the reaction temperature is 110 ° C, the reaction time is 5 h, and cooled to room temperature to obtain a mixture of compounds containing antioxidant groups and toluene;

[0017] Add 7.2g of acrylic acid to the mixture of the compound containing antioxidant groups and toluene, control the temperature at 140°C, react for 6.5h, cool to room temperature, wash with distilled water until neutral, then distill off the water and xylene under reduced pressure , to obtain a reactive antioxidant with a terminal double bond;

[0018] Add the obtained reactive antioxidant with terminal double bond to the polymerization reaction system of octene, in AlCl 3 The p...

Embodiment 2

[0020] Weigh 11.8g of hexanediol and 27.8g of β-3,5-di-tert-butyl-4-hydroxyphenylpropionic acid into a 250mL three-neck flask reaction device equipped with electric stirring, thermometer, water separator and condenser, and add the catalyst The mass fraction is 0.5% stannous chloride, and then 70 mL of xylene is added as a solvent, the temperature is controlled at 140 ° C, the reaction is carried out for 4 hours, and the mixture is cooled to room temperature to obtain a mixture of compounds containing antioxidant groups and toluene;

[0021] Add 7.2 g of acrylic acid to the mixture of compounds containing antioxidant groups and toluene, control the temperature at 130 ° C, react for 7 h, cool to room temperature, wash with distilled water until neutral, and then distill off water and xylene under reduced pressure to obtain Reactive antioxidants with terminal double bonds;

[0022] The obtained reactive antioxidant with terminal double bond is added to the polymerization reaction...

Embodiment 3

[0024] Weigh 11.8g of hexanediol and 27.8g of β-3,5-di-tert-butyl-4-hydroxyphenylpropionic acid into a 250mL three-neck flask reaction device equipped with electric stirring, thermometer, water separator and condenser, and add the catalyst The mass fraction is 0.5% p-toluenesulfonic acid, and then 70 mL of xylene is added as a solvent, the reaction temperature is 150 ° C, the reaction time is 6 h, and cooled to room temperature to obtain a mixture of compounds containing antioxidant groups and toluene;

[0025] Add 7.2 g of acrylic acid to the mixture of compounds containing antioxidant groups and toluene, control the temperature at 130 ° C, react for 7 h, cool to room temperature, wash with distilled water until neutral, and then distill off water and xylene under reduced pressure to obtain Reactive antioxidants with terminal double bonds;

[0026] The obtained reactive antioxidant with terminal double bond is added to the polymerization reaction system of 1-dodecene, in BF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com