Sound energy collector by adopting phonon crystal and electromechanical Helmholtz resonator

A phononic crystal and resonator technology, which is applied in the field of new energy collection, can solve the problems of inefficient collection efficiency and weak sound amplification ability, and achieve the effect of high-efficiency sound energy collection efficiency, high-efficiency sound energy collection, and sound wave amplification improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

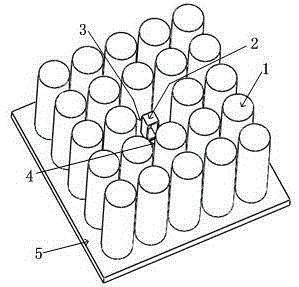

[0023] The specific embodiment of the present invention is as figure 1 as shown,

[0024] In this embodiment, a sub-acoustic energy collector using phononic crystals and electromechanical Helmholtz resonators includes an electromechanical Helmholtz resonator, a phononic crystal resonant cavity 1 , a support column 4 and a base 5 .

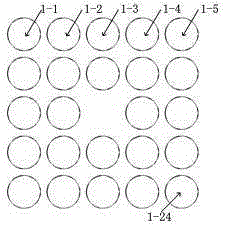

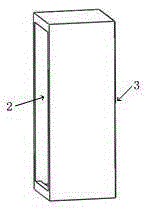

[0025] Phononic crystal resonator 1 is formed by arraying 24 round rods (1-1, 1-2, ..., 1-24) at equal intervals along two directions perpendicular to each other in the same plane, and the bottom of which is bonded on base 5. The electromechanical Helmholtz resonator is composed of a Helmholtz resonator 2 and a composite piezoelectric transducer 3, and the composite piezoelectric transducer 3 is bonded to the back of the Helmholtz resonator 2 in a fixed manner at the peripheral end. cavity position; wherein the composite piezoelectric transducer 3 is formed by bonding the piezoelectric sheet 3-2 on the elastic metal sheet 3-1. The combination of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com