Complex machinery product assembling sequence programming method based on firework algorithm

A technology for assembly sequence planning and fireworks algorithm, applied in the directions of calculation, data processing application, prediction, etc., can solve problems such as difficulty in guaranteeing the rationality and superiority of assembly sequence, increase in manufacturing cost, prolong development cycle, etc., so as to shorten the product development cycle. , The effect of reducing product manufacturing cost and planning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing. Embodiments of the present invention include, but are not limited to, the following examples.

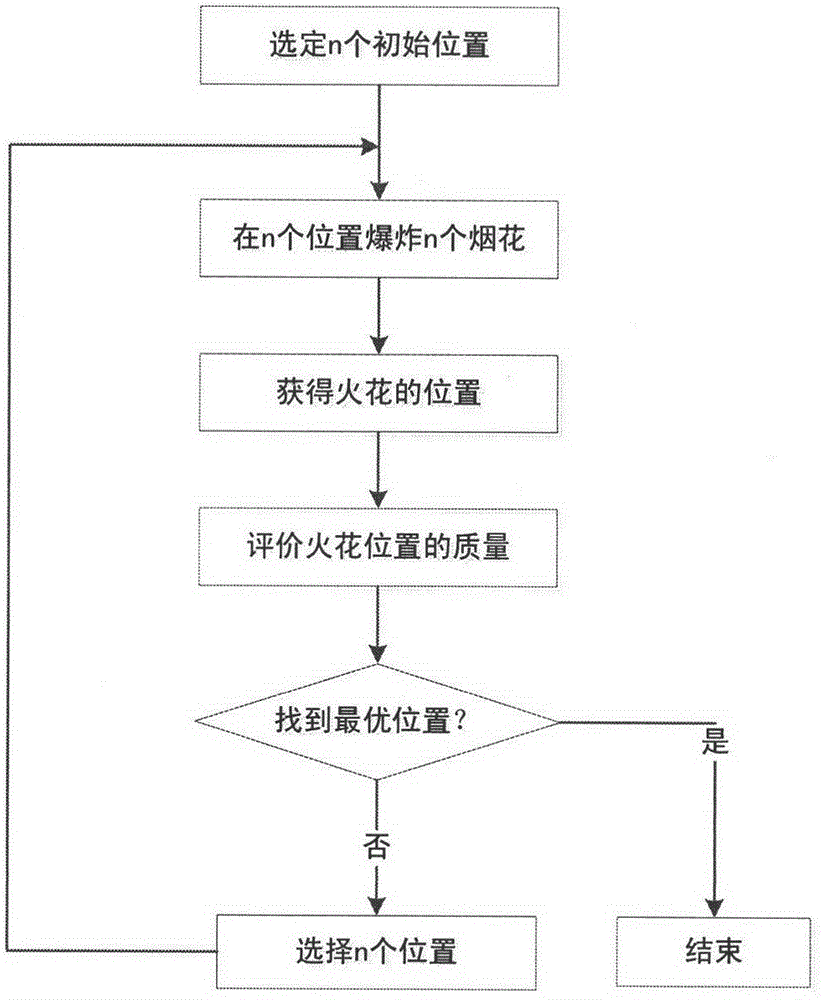

[0018] refer to figure 1 , an assembly sequence planning method for complex mechanical products based on fireworks algorithm, the steps are as follows:

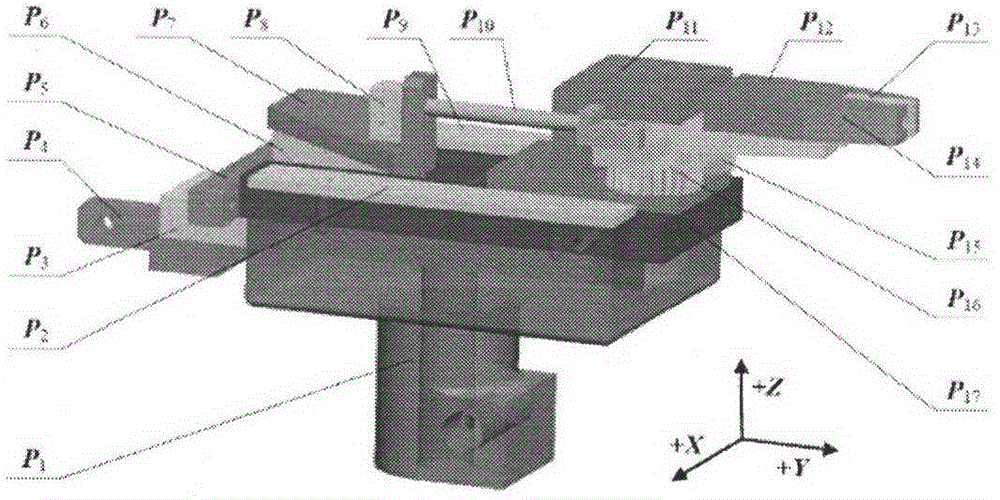

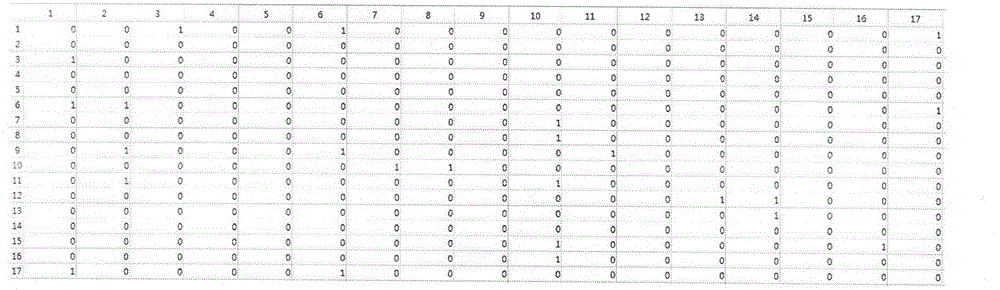

[0019] Step 1: Modeling product assembly based on assembly, see figure 2 , to establish a foundation for solving the assembly sequence based on the fireworks algorithm; determine the initial interference matrix, stable support matrix and assembly tool transformation times of the assembly, see image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 shown;

[0020] step 1 image 3 1 means that part i interferes with part j when it is assembled along the coordinate axis + x direction, and 0 means that part i does not interfere with part j when it is assembled along the coordinate axis + x direction;

[0021] step 2 Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com