A Steam Turbine Flow Curve Identification and Optimization Method Based on Power Value Calculation

A technology of flow curve and optimization method, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., and can solve problems such as insufficient response load, inconsistent and excessively large flow characteristic setting curves of valve groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

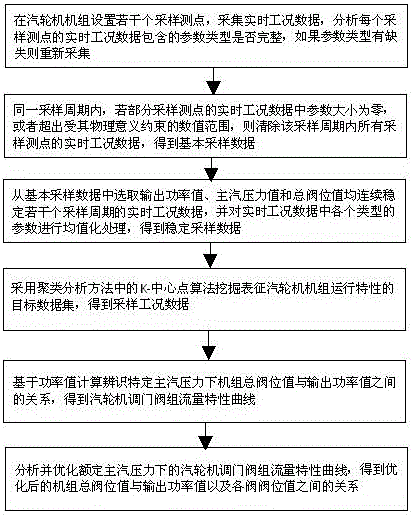

[0031] Such as figure 1 As shown, the steam turbine flow curve identification and optimization method based on power value calculation of the present invention includes the following steps:

[0032] A. Set several sampling points in the steam turbine unit, and set the sampling period and sampling duration, collect the real-time working condition data of the steam turbine unit, and analyze whether the real-time working condition data of each sampled measuring point contains complete parameter types. If the parameters are If the type is missing, re-collect, if the parameter type is not missing, then go to step B.

[0033] B. For all sampling points, if in the same sampling period, one or more sampling points have a parameter size of zero in the real-time working condition data, that is, vacant working condition data appears, or the parameter size exceeds the physical meaning constraint When abnormal working condition data occurs, the real-time working condition data of all sampling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com