Rice milling machine

A technology of rice milling machine and rice milling mechanism, which is applied in the field of rice milling machines, can solve the problems of lack of freedom of assembly, etc., and achieve the effect of good assembly workability, good assembly freedom, and good assembly workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described with reference to the drawings.

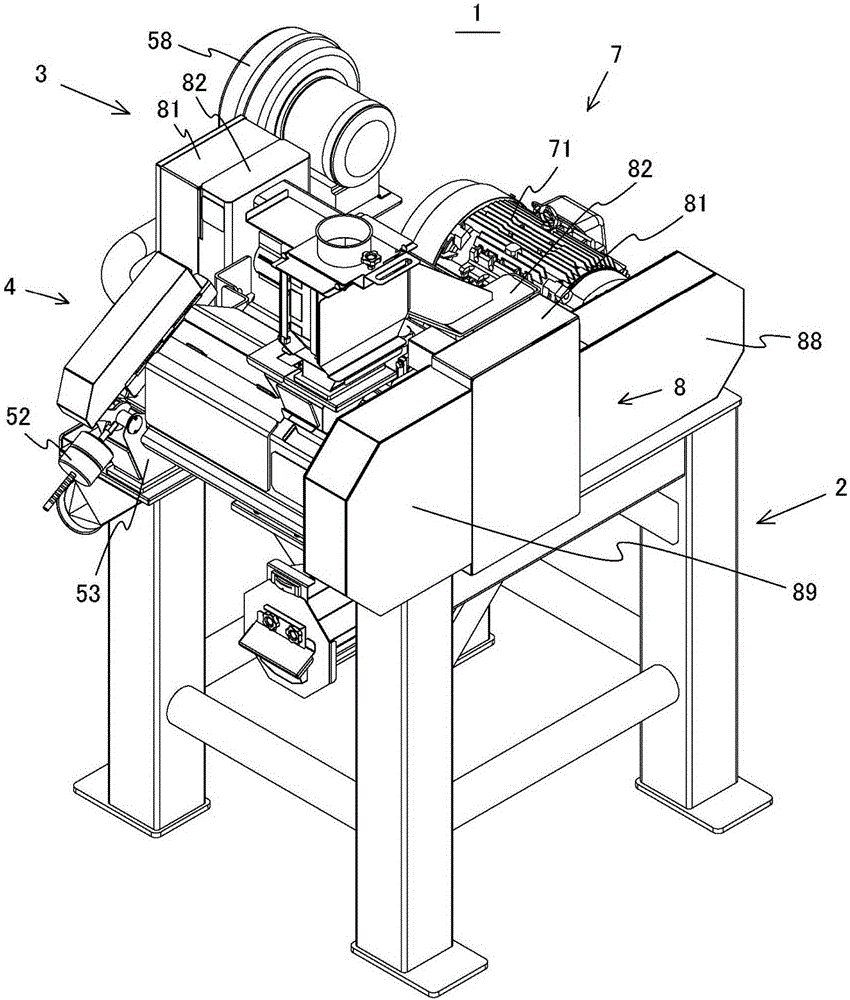

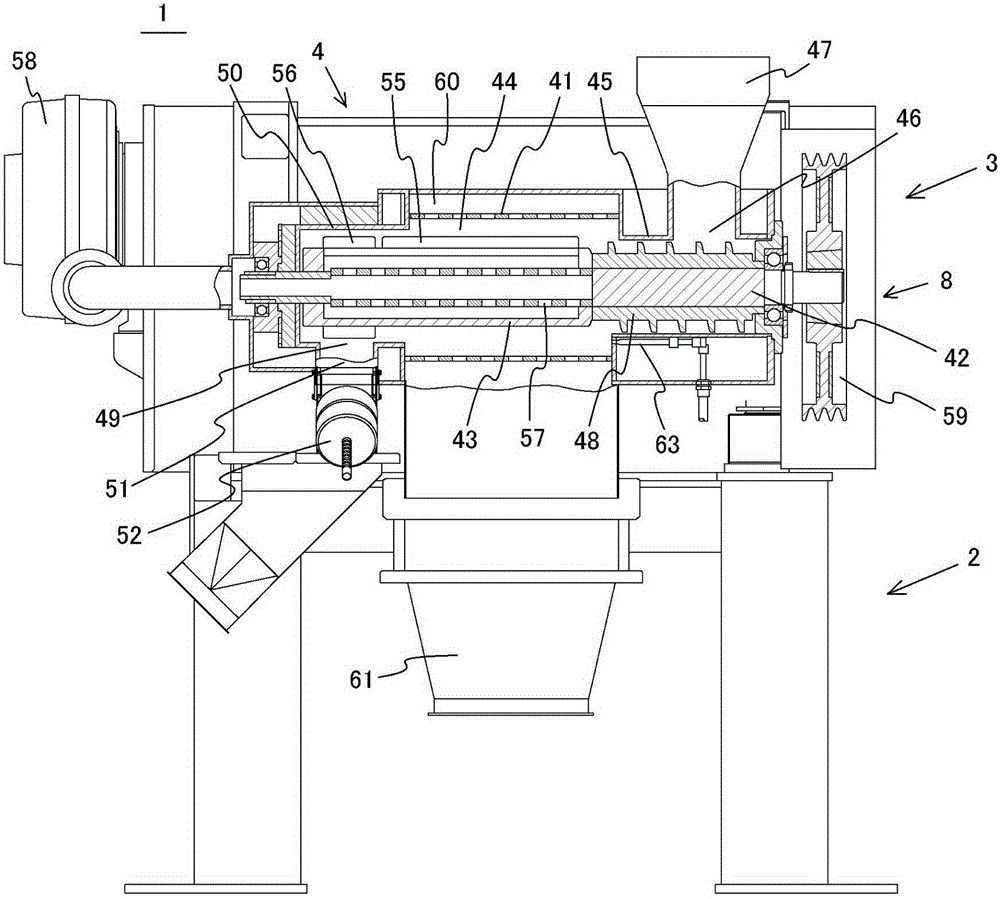

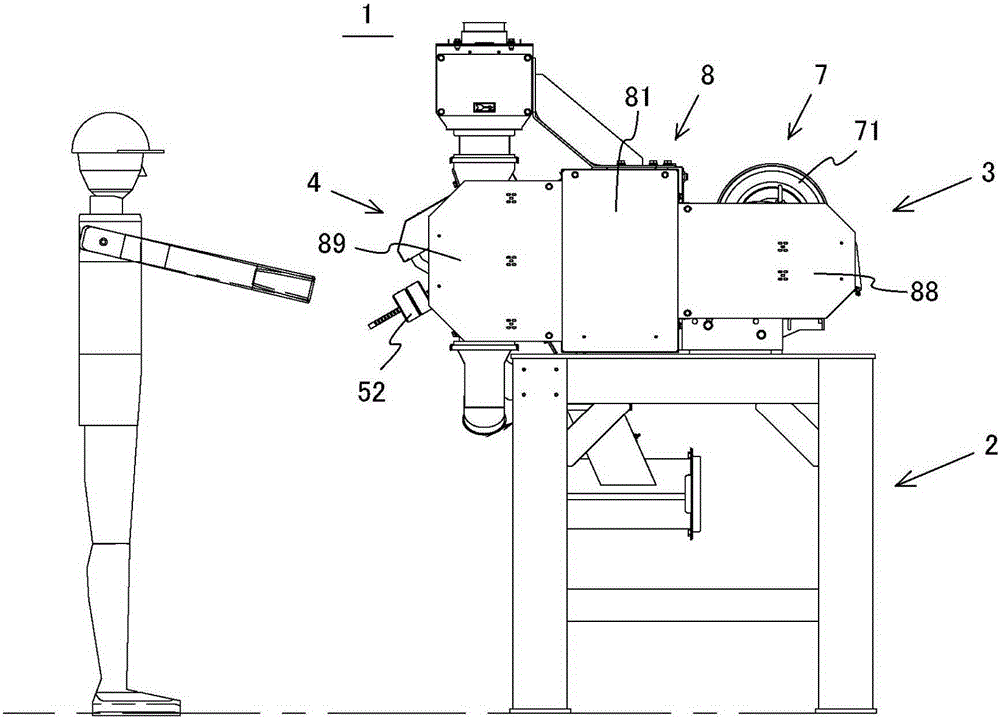

[0046] figure 1 The perspective view which shows the rice mill of embodiment of this invention. figure 2 express figure 1 The front view of the rice mill is a partial cross-sectional view of the fine pounding part. image 3 express figure 1 Right side view of the rice mill.

[0047] The rice mill 1 according to the embodiment of the present invention is a single-seat type horizontal axis type rice mill in which one rice milling mechanism 3 is mounted on a base frame 2 .

[0048] The above-mentioned rice milling mechanism 3 includes: a cylindrical finishing wire 41 and a whitening roller 43 mounted on a main shaft 42 and rotatably arranged in the above-mentioned finishing wire 41 . The finishing part 4 formed by forming the finishing chamber 44 between the above-mentioned whitening rollers 43; the driving part 7 having the motor 71 that rotates the main shaft 42 equipped with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com