Preheating control method for motor winding

A technology of preheating control and motor winding, which is applied in motor generator control, AC motor control, electronic commutation motor control, etc., and can solve problems such as motor noise at shutdown and temperature reduction of motor windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention aims to propose a motor winding preheating control method to solve the problems of motor winding temperature reduction, IPM overcurrent shutdown and high motor noise during preheating existing in the motor winding preheating scheme in the traditional technology.

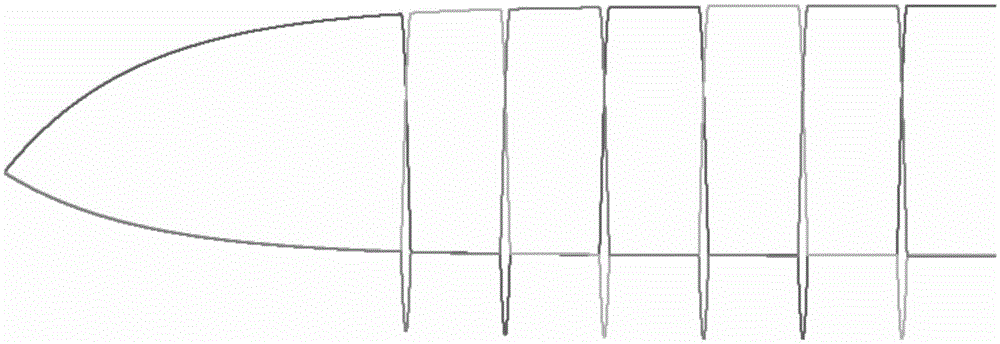

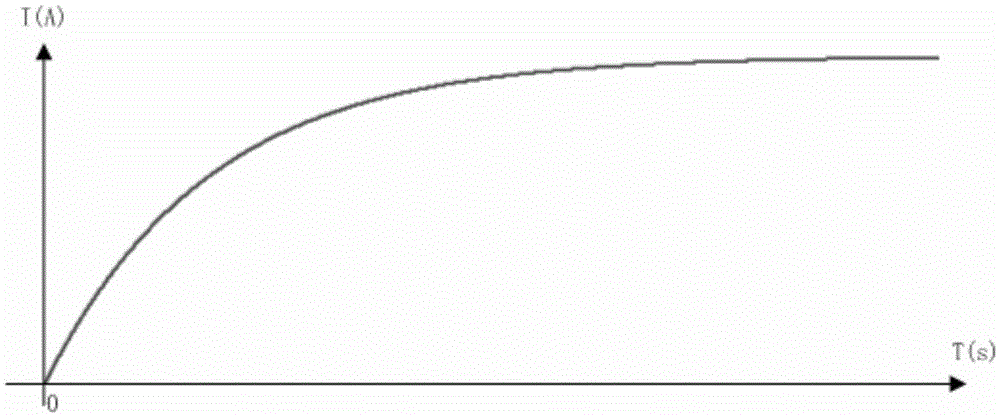

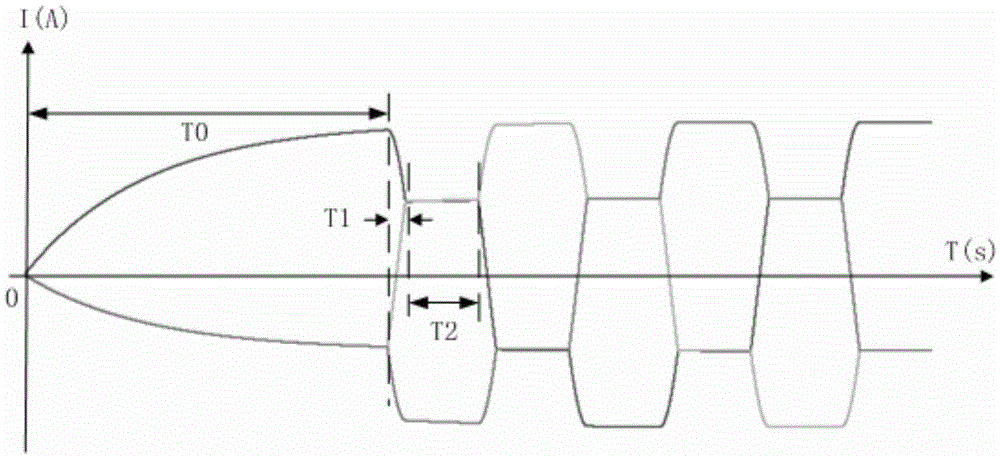

[0024] When preheating is required, first modify the carrier frequency of the inverter to a value higher than the current carrier frequency, generally greater than 16KHz, to achieve low-noise preheating, and restore the carrier frequency of the inverter after the preheating is over. After entering the warm-up, the first positioning, the d-axis positioning target current I d0 Slowly increase from 0 to the target current I through a low-pass filter d0 ,Such as figure 2 As shown, avoid the occurrence of the IPM overcurrent problem caused by the sudden change of current. At this time, the q-axis positioning current command value I q is 0, positioning angle γ 0 is 0, the d-axis positioning curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com