Brown-granulated-sugar re-dissolution constant current system

A brown sugar and flow system technology, which is applied in the direction of various fluid ratio control and flow control using electric devices, can solve the problems of uneven flow rate, unreasonable ratio of coarse syrup and brown sugar back-dissolving, etc., and achieve precise control process , strong versatility, and the effect of improving output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention is described in detail below in conjunction with embodiment:

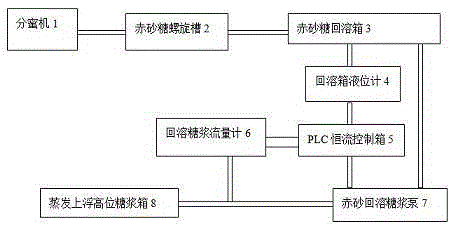

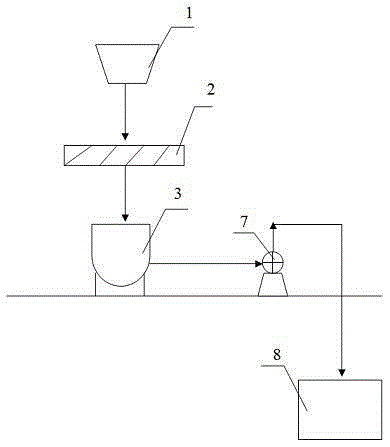

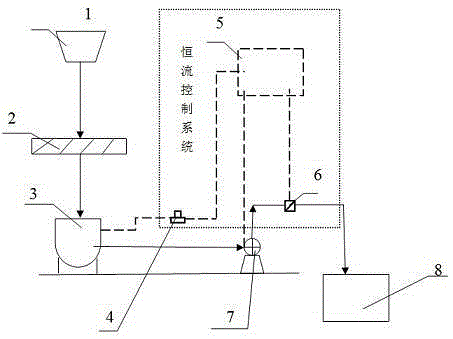

[0023] Such as figure 1 and image 3 As shown, the red granulated sugar remelting constant flow system of the present invention includes a honey separator 1, a red granulated sugar spiral groove 2, a red granulated sugar remelting tank 3, a red granulated sugar remelting syrup pump 7, an evaporating and floating high-level syrup tank 8, and the above components Connected sequentially through liquid delivery pipelines; a constant current control system is also provided between the brown sugar remelting tank 3 and the evaporation and floating high level syrup tank 8, and the constant current control system includes a remelting tank liquid level gauge 4, a PLC constant current Control box 5, remelting syrup flowmeter 6; said remelting tank level gauge 4 and remelting syrup flowmeter 6 are respectively connected to the signal input end of the PLC constant current co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com