Box type harmless treatment oven

A harmless treatment and burning technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of human health damage, surrounding environmental pollution, high cost, etc., to eliminate side leakage, reduce energy consumption, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

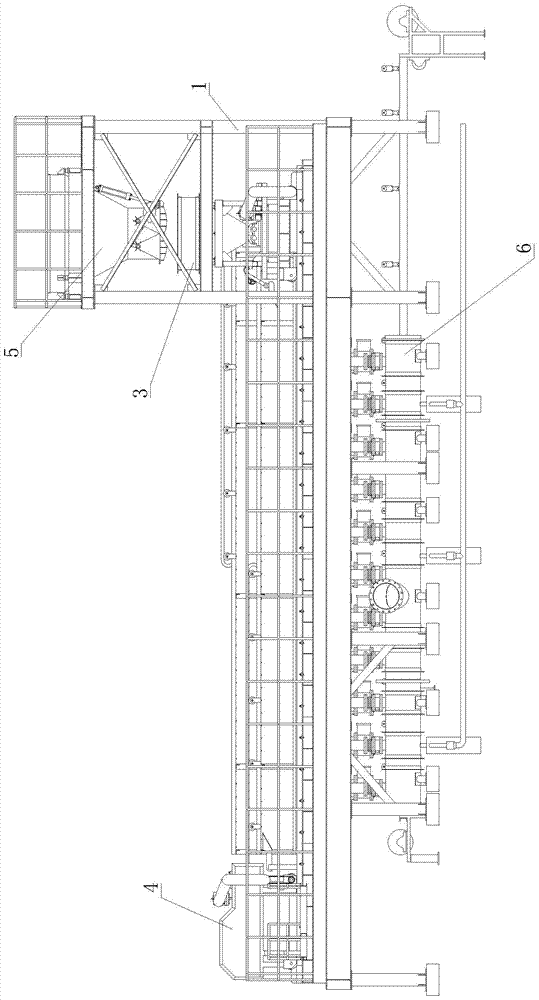

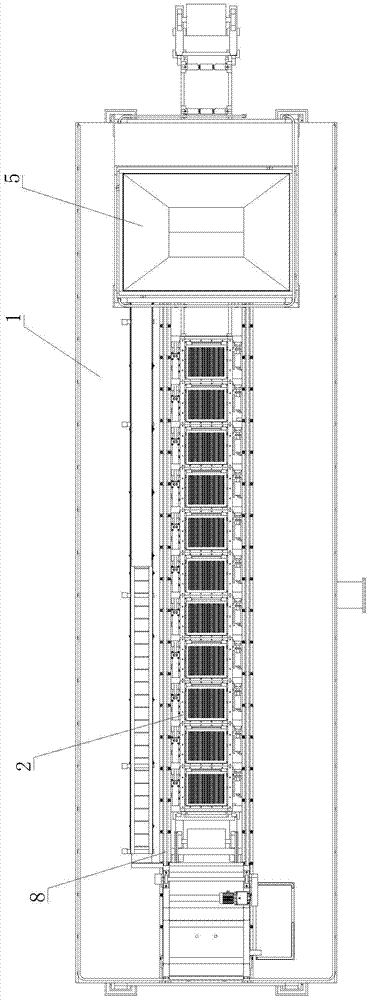

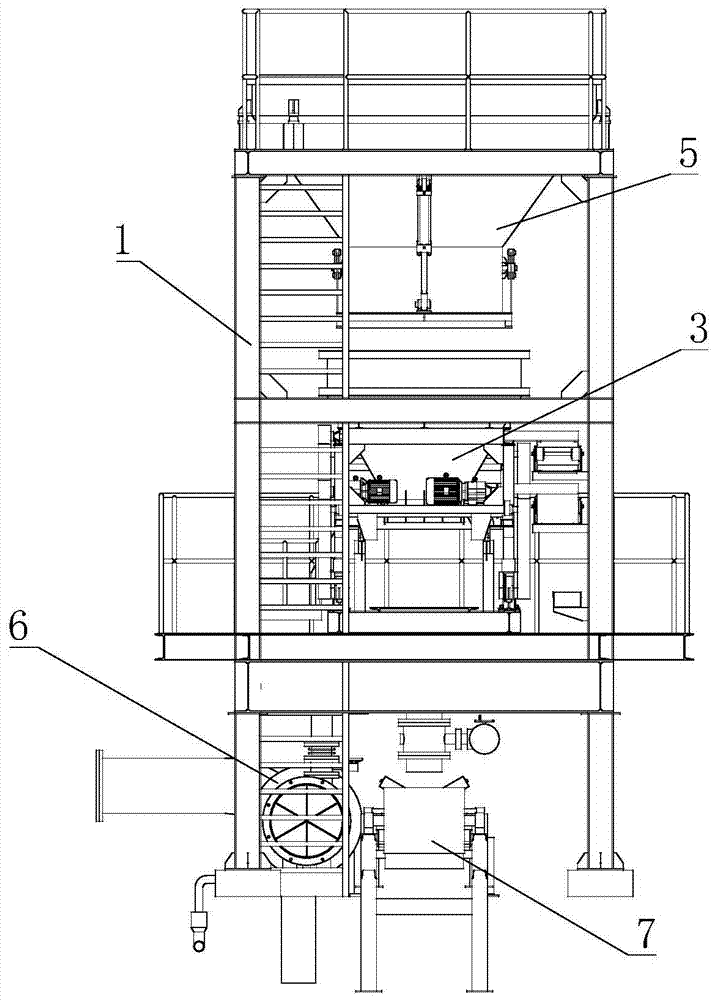

[0033] Such as figure 1 , figure 2 and image 3 As shown, the box-type harmless treatment roasting furnace of the present invention includes a frame body 1, a roasting box 2, a distribution car 3, an ignition train 4, a mixture silo 5, an air duct 6 and a discharge conveyor 7. The mixed material silo 5 is set on the frame body 1. There is an opening at the bottom of the mixed material silo 5, which is opened or closed by a valve that can be opened and closed automatically. The mixed material silo 5 holds the sludge mixture to be treated. . A plurality of baking boxes 2 are arranged sequentially on the frame body 1, and the discharge conveyor 7 is located below the baking boxes 2, and the discharge conveyor 7 of this embodiment is a belt conveyor. On the frame body 1, the two sides of the baking box 2 are provided with tracks 8 extending along the arrangement direction of the baking box 2. move above. One end of the track 8 extends below the mixed material silo 5, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com