Clothes tail-splitting type zipper sewing template and sewing method thereof

A zipper and tail type technology is applied in the field of garment open-end zipper sewing templates, which can solve the problems of inability to reserve the force of the zipper, uneven sewing of the zipper, different lengths, etc., so as to improve the sewing quality of the zipper and ensure the smoothness of the zipper. , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

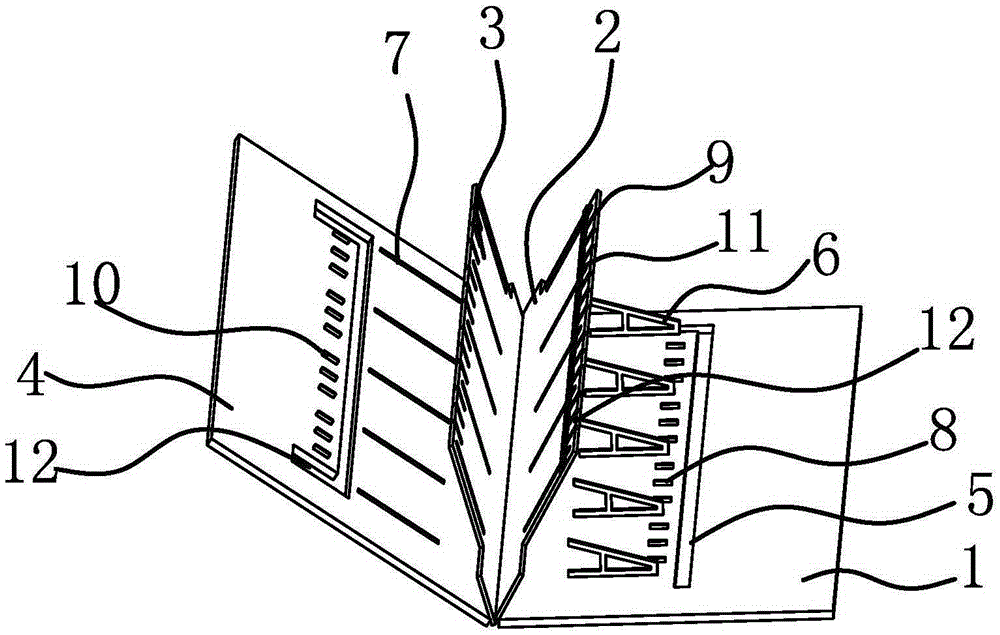

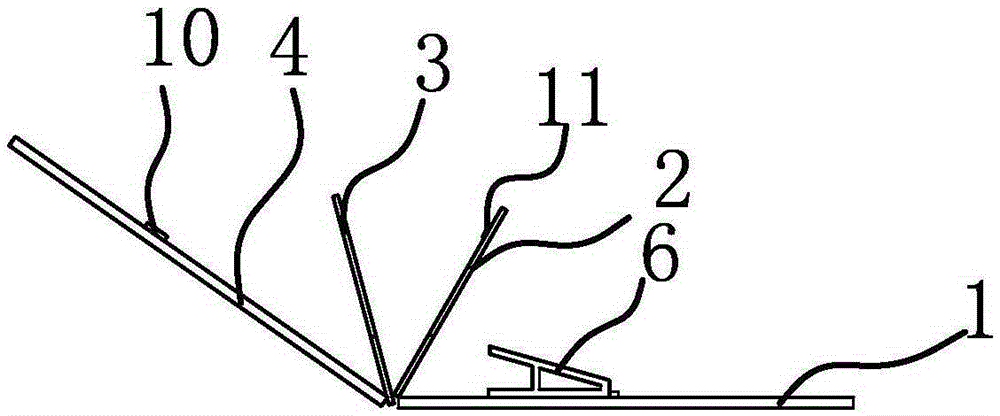

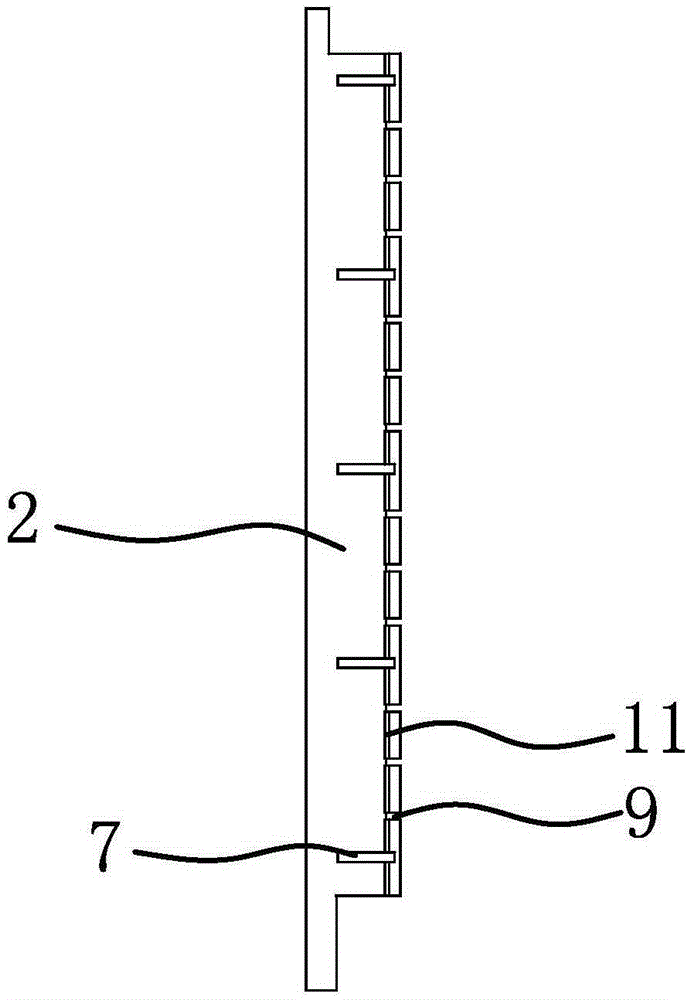

[0025] Such as Figure 1~4 As shown, the garment open-end zipper sewing template includes a base plate 1, a lining plate 2, a zipper plate 3, and a panel 4 arranged in sequence, and the lining plate 2, the zipper plate 3, and the panel 4 are all hinged to the base plate. 1 and can be superimposed on each other, after the bottom plate 1 and the panel 4 are superimposed, a sewing groove 5 consistent with the shape of the zipper stitching is provided at the same position, and several clamping parts 6 are provided on the bottom plate 1. The panel 4, the lining pressing plate 2, and the zipper pressing plate 3 are provided with a clamping piece relief hole 7 for the clamping piece 6 to pass through, and the bottom plate 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com