Adjustable working roll for carding machine

A carding machine and work roll technology, used in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of inconvenience and inconvenience of needle teeth replacement, improve carding efficiency, avoid grabbing fibers, and easy to operate handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

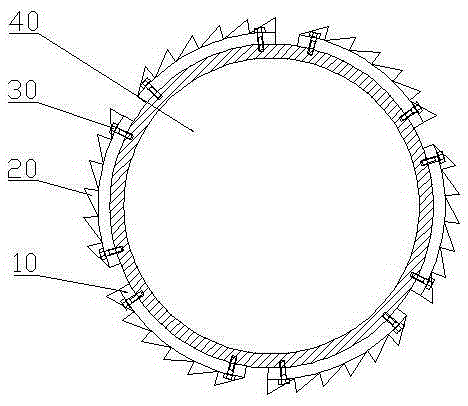

[0012] Such as figure 1 As shown, the adjustable working roll of the carding machine includes: a cylinder 40, a pin tooth plate 10, and a bolt 30. The pin tooth plate 10 is an arc-shaped plate matched with the cylinder 40. The curvature of the surface is the same. Pin teeth 20 are arranged on the pin tooth plate 10 . The pin-toothed plates 10 are arranged parallel and evenly in the axial direction of the drum 40 , and the pin-toothed plates 10 are arranged in a staggered manner in the circumferential direction of the drum 40 , that is, in the axial direction of the drum 40 . Each row of pin tooth plates 10 is arranged in parallel and evenly. However, each row of pin tooth plates 10 is arranged in a staggered manner. The pin-tooth plate 10 is connected to the drum 40 through bolts 30 . In addition, the pin teeth 20 are right-angled triangles, and the straight sides of the pin teeth 20 of the right-angled triangle are connected to the pin-tooth plate 10 . At this time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com