A sorting and recycling system and method for tin stripping waste liquid

A recovery system and recovery method technology, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sludge/sewage treatment, etc., can solve problems such as low filtration efficiency and small filter hole gaps, and achieve simple and compact structure, work High efficiency and ingenious settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

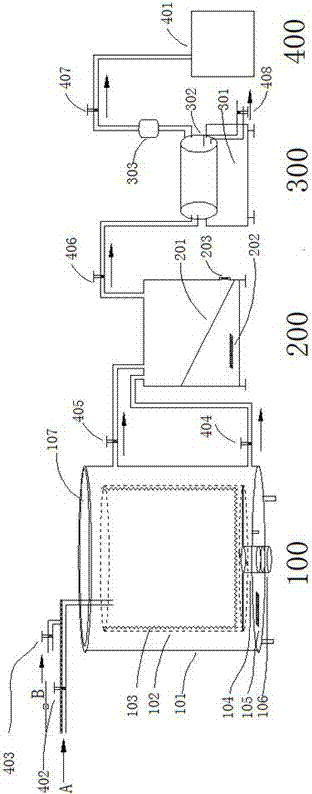

[0044] like figure 1 As shown, a classification recovery system for tin stripping waste liquid in the present invention includes a suction filtration system 400 , an aging filter 100 , a constant temperature distiller 200 and a cooling collection tank 300 .

[0045] The aging filter 100 is provided with an aging filter chamber 101, a porous centrifuge tank 102, a filter bag 103, a heater 105 and a centrifugal drive device. The centrifugal drive device is made up of a motor 106 and a centrifugal fixed shaft 104. The bottom of the centrifuge tank 102 is fixed, and the motor 106 drives the centrifugal fixed shaft 104 to rotate. The filter bag 103 is disposed in the porous centrifuge tank 102 . The main body of the aging filter 100 is the aging filter chamber 101. The motor 106 at the bottom and the centrifugal fixed shaft 104 drive the porous centrifugal tank 102 and the filter bag 103 assembled by the aging filter 101. The upper end of the aging filter chamber 101 is connected ...

Embodiment 2

[0060] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. A sorting recovery method of a kind of tin stripping waste liquid of the present embodiment is as follows:

[0061] Open the valve 402, and the tin stripping wastewater flows into the pipeline at a rate of 2L / min (total tin content 120.5g / L, Cu 2+ The concentration is 18.4g / L), after 3 minutes, open the valve 403 at the same time, inject the PMA dilute solution (flocculant) with a concentration of 1% at a rate of 15mL / min, after a period of time, the liquid surface covers the bottom of the aging filter to form After sealing the liquid level, turn on the heater 105 in the aging filter 100, set the constant temperature to 50°C, and let it stand for 1 hour; close the valve 405, open the valve 404, start the vacuum mode, and start the motor 106 at the same time to perform...

Embodiment 3

[0064] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or 2, and the features not explained in this embodiment are explained in Embodiment 1 or 2, and will not be repeated here. A sorting recovery method of a kind of tin stripping waste liquid of the present embodiment is as follows:

[0065] Open the valve 402, and flow into the pipeline at a speed of 5L / min to remove tin wastewater (total tin content 94.6g / L, Cu 2+ The concentration is 15.7g / L), after 5 minutes, open the valve 403 at the same time, and inject the cationic polyacrylamide dilute solution with a concentration of 5% at a rate of 5mL / min. After a period of time, the liquid surface covers the bottom of the aging filter 100 to form After sealing the liquid surface, turn on the heater 105 in the aging filter 100, set the constant temperature to 80°C, and let it stand for 1 hour; close the valve 405, open the valve 404, start the vacuum mode, and start the motor 106 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com