Interference method for two-dimension code of product wrapped by transparent film

A product two-dimensional code, transparent film technology, applied in the field of printing and packaging, can solve the problems of two-dimensional code registration, lack of positioning and registration, etc., and achieve the effect of practical printing quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

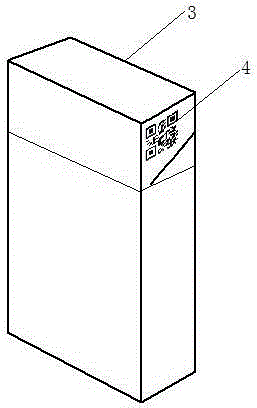

[0049] Such as figure 1 , image 3 As shown, the cigarettes are packaged in hard packets.

[0050] In the first step, the cigarette manufacturer requires the supplier’s printing factory to print unique two-dimensional codes (4) on designated positions on the cigarette case—the product packaging (3) while printing and producing. After the quality inspection is 100% qualified, the cigarette case will be handed over to the cigarette manufacturer for standby.

[0051] In the second step, on the cigarette packaging production line, the cigarette manufacturer uses a transparent film (2) without printed graphics and a pull wire (1) to wrap each cigarette case loaded with cigarettes.

[0052] The third step is to scan and read the QR code (4) on each cigarette case and its corresponding carton for a period of time after the cigarette case is loaded into the carton and before the carton is sealed, so that the carton and Correspondence is established between the data of the box, so a...

Embodiment 2

[0057] Such as Figure 4 As shown, a small pack of cigarettes is produced.

[0058] In the first step, the cigarette manufacturer requires the supplier’s printing factory to print unique two-dimensional codes (4) on designated positions on the cigarette case—the product packaging (3) while printing and producing. After the quality inspection is 100% qualified, the cigarette case will be handed over to the cigarette manufacturer for standby.

[0059] In the second step, the cigarette manufacturer requires the supplier of the transparent film (2) to add a laser masterbatch to the film raw material during production, so as to produce a laser masterbatch that can be carbonized and discolored on the transparent film (2). film. Laser masterbatch is a commercially available chemical product, so there is no need to go into details in this article.

[0060] In the third step, the cigarette manufacturer wraps the cigarettes with a transparent film (2) on the packaging production line...

Embodiment 3

[0066] Such as Figure 5 As shown, a kind of bowl instant noodles are produced.

[0067] In the first step, the instant noodle manufacturer requires the supplier’s printing factory to print unique QR codes (4) on designated positions on the bowl cover—the product packaging (3) at the same time as printing and production. After the quality inspection is 100% qualified, the bowl cover will be handed over to the instant noodle manufacturer for use.

[0068] In the second step, the instant noodle manufacturer wraps the instant noodle products with a heat-shrinkable transparent film (2) without printed graphics on the instant noodle packaging production line.

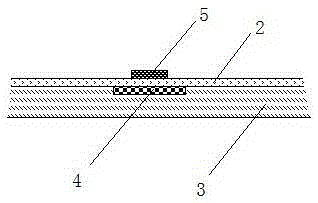

[0069] The third step is to use a solvent-based inkjet printer to print opaque interference patterns on the packaged instant noodles of bowls, the surface of the transparent film (2), and the positions of the two-dimensional code (4). Text (5) - production date. Thereby, the two-dimensional code (4) is blocked and kept se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com