Automatic clamp collating machine

A fully automatic, collating machine technology, applied in the direction of printing, book binding, composite continuous process of book processing, etc., can solve the problem of uneven timing of loose pages, increase work efficiency, and uneven timing, and achieve rigorous overall structural design. , Improve work efficiency, use the effect of excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the utility model is described further.

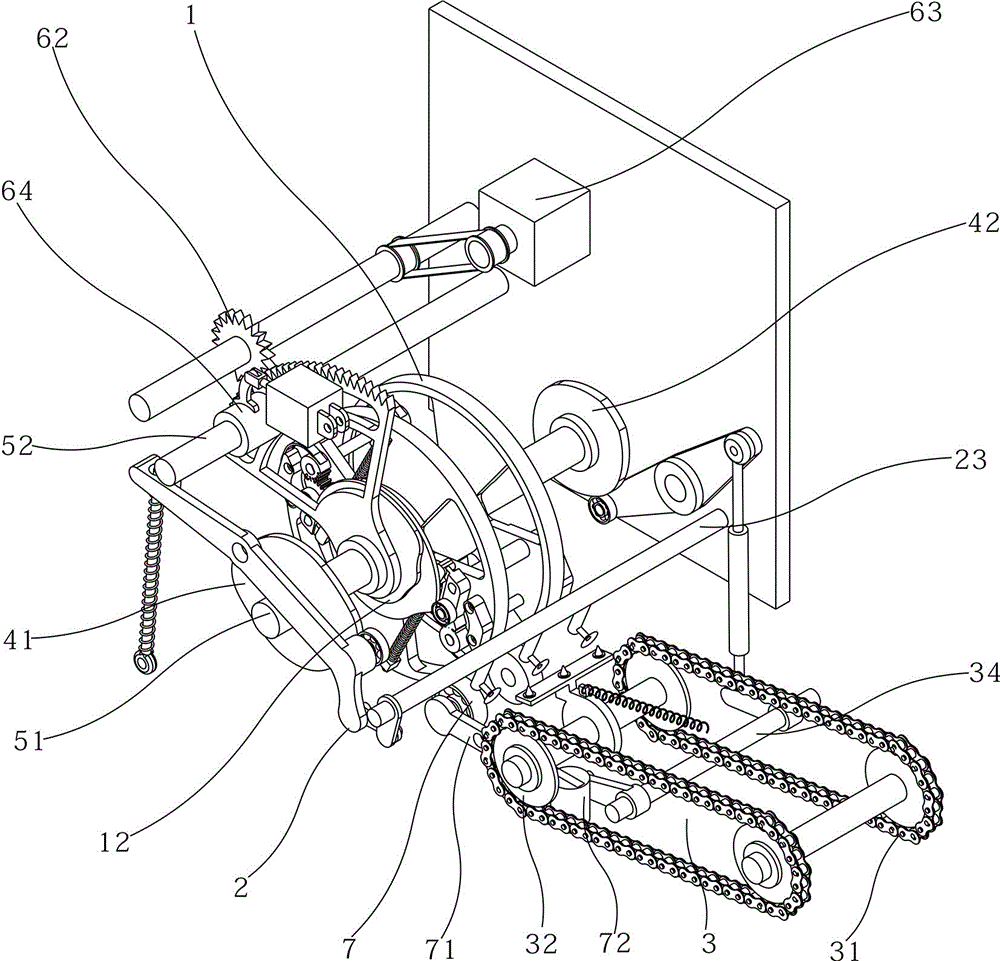

[0028] Such as figure 1 and figure 2 The full-automatic clamp-type collating machine shown includes a page clamping wheel 1 , a page suction device 2 , and a page pushing device 3 .

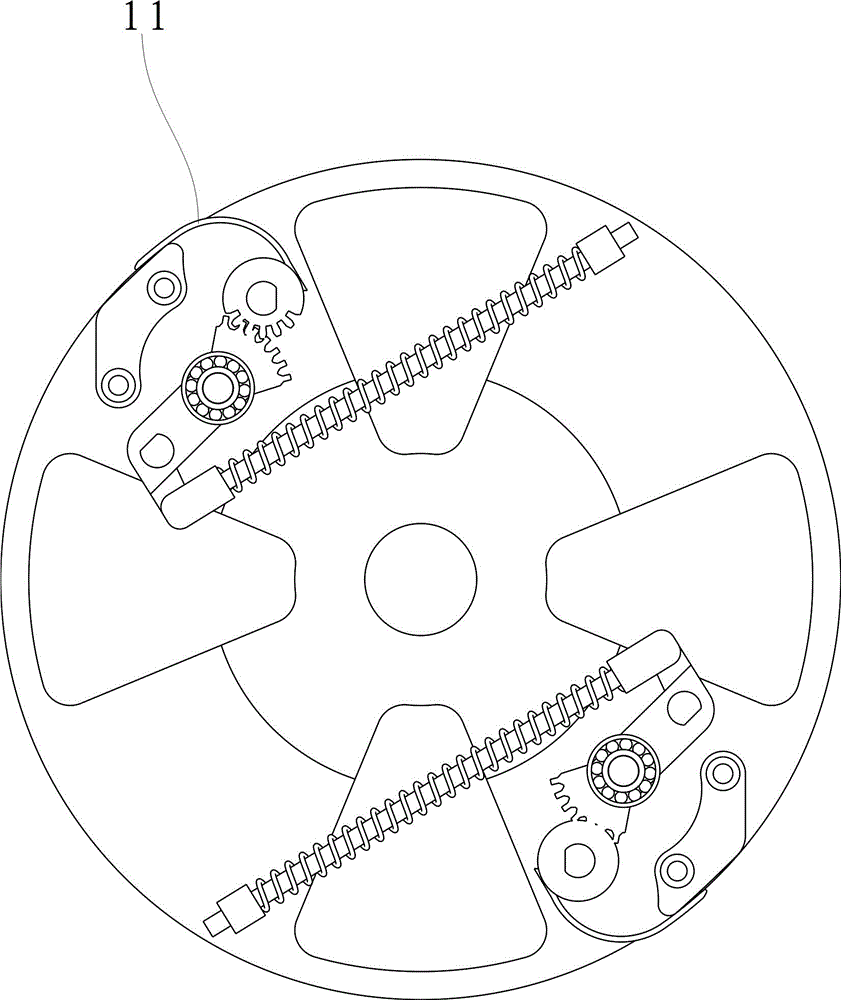

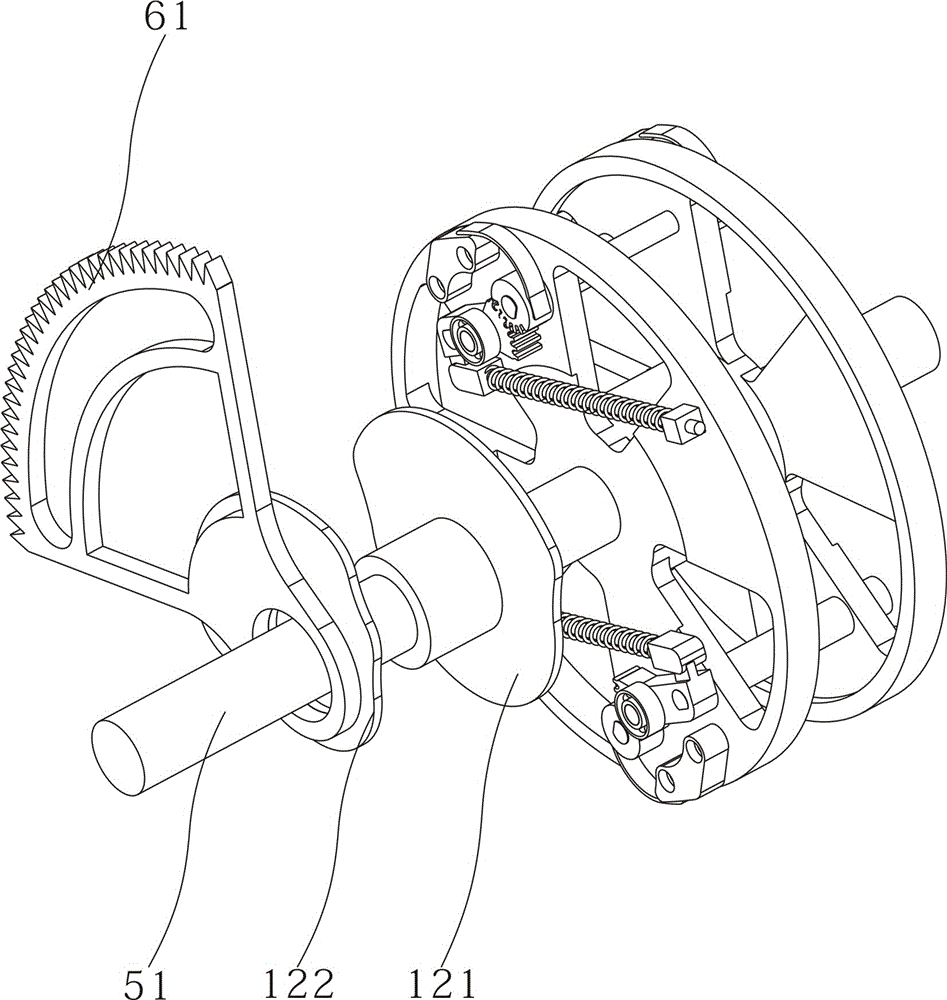

[0029] Such as image 3 The shown page clamp wheel 1 is arranged on the main shaft 51, and the side circumference of the page clamp wheel 1 is provided with two opposite grippers 11, and the grippers 11 realize the opening and closing operation through the fan-shaped cam 12; The front and rear parts of the main shaft 51 are respectively provided with a page suction cam 41 and a page pushing cam 42, and the page suction cam 41 and the page pushing cam 42 are respectively connected to the corresponding page suction device 2 and page pushing device through a transmission mechanism. 3.

[0030] The position of the convex point on the right side of the fan-shaped cam 12 corresponds to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com