Power supply device with rollers

A technology of electric power supply and roller, applied in the direction of circuits, electrical components, parts of connecting devices, etc., can solve problems such as weakening, difficulty in inserting clamping force, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

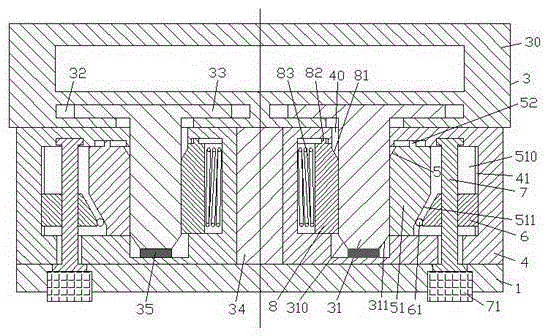

[0009] Combine below figure 1 The present invention will be described in detail.

[0010] According to an embodiment of an electric power supply device with rollers, it includes a pin type insertion device 3 and a seat hole type fixing device. The pin type insertion device 3 includes a body part 30 and a central axis about the body part 30 Two pin-type plugs 31 are symmetrically arranged, and the upper parts of the two pin-type plugs 31 are provided with guide horizontal parts 33 for slidably connecting with the two slide grooves 32 in the body part 30. Correspondingly one of them is slidingly fitted and bears the force load in the up and down direction. The seat hole type fixing device includes a base 1 and two mounting brackets 4 fixed on the base 1 and arranged symmetrically with respect to the central axis, each The installation frame 4 is provided with a slot 40 for inserting a corresponding one of the two pin plugs 31 , each of the installation frames 4 is on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com