Branch line coupler and manufacture method thereof

A manufacturing method and coupler technology, applied in the microwave field, can solve the problems of inconvenient connection, lack of common mode suppression ability, and inability to suppress environmental noise well, so as to achieve the effect of suppressing environmental noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] see figure 1 It is a schematic structural diagram of a branch line coupler according to an embodiment of the present invention. The branch line coupler in the embodiment of the present invention includes: four balanced ports, the first balanced port A, the second balanced port B, the third balanced port C and the fourth balanced port D, each balanced port Both are composed of two single ports, the common mode signal is suppressed, and the differential mode signal needs to meet the same amplitude and 180° phase difference at the ports.

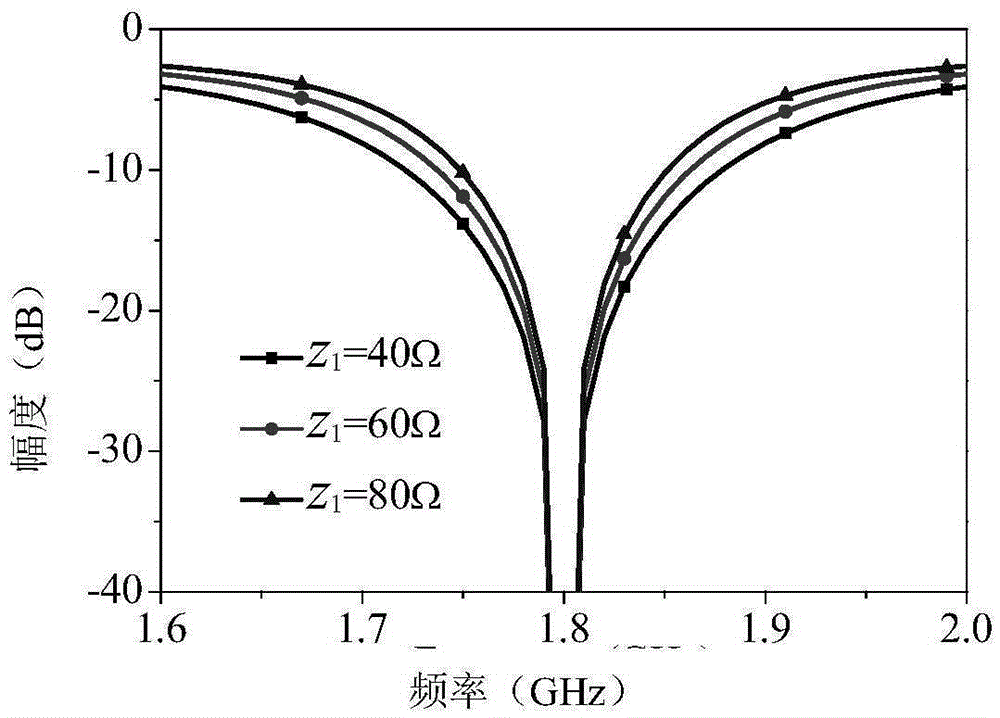

[0051] Specifically, see figure 1 , the first balanced port A includes single port 1 and single port 2, and the passing impedance between single port 1 and 2 is Z 1 The half-wavelength transmission line 10 is connected. The second balanced port B includes single port 3 and single port 4, and the passing impedance between single port 3 and 4 is Z 1 The half-wavelength transmission line 10 is connected. The third balanced port C inclu...

Embodiment 2

[0090] see Figure 8 It is a flowchart of a manufacturing method of a branch line coupler according to an embodiment of the present invention. It includes the following steps:

[0091] S1. Pass the first balanced port and the fourth balanced port through impedance Z 2 A quarter-wavelength transmission line connection;

[0092] S2, passing the first balanced port and the second balanced port through impedance Z 3 A quarter-wavelength transmission line connection;

[0093] S3, passing the second balanced port and the third balanced port through impedance Z 2 A quarter-wavelength transmission line connection;

[0094] S4, passing the third balanced port and the fourth balanced port through an impedance of Z 3 A quarter-wavelength transmission line connection;

[0095] S5. Pass the two single-ports of each balanced port through impedance Z 1 half-wavelength transmission line connection.

[0096] In one embodiment, the method of the embodiment of the present invention also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical length | aaaaa | aaaaa |

| Electrical length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com