A full-surface three-dimensional measuring device for complex columnar workpieces and its measuring method

A technology for three-dimensional measurement and columnar workpieces, applied in the field of three-dimensional measurement, to achieve the effect of insensitivity to posture and position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

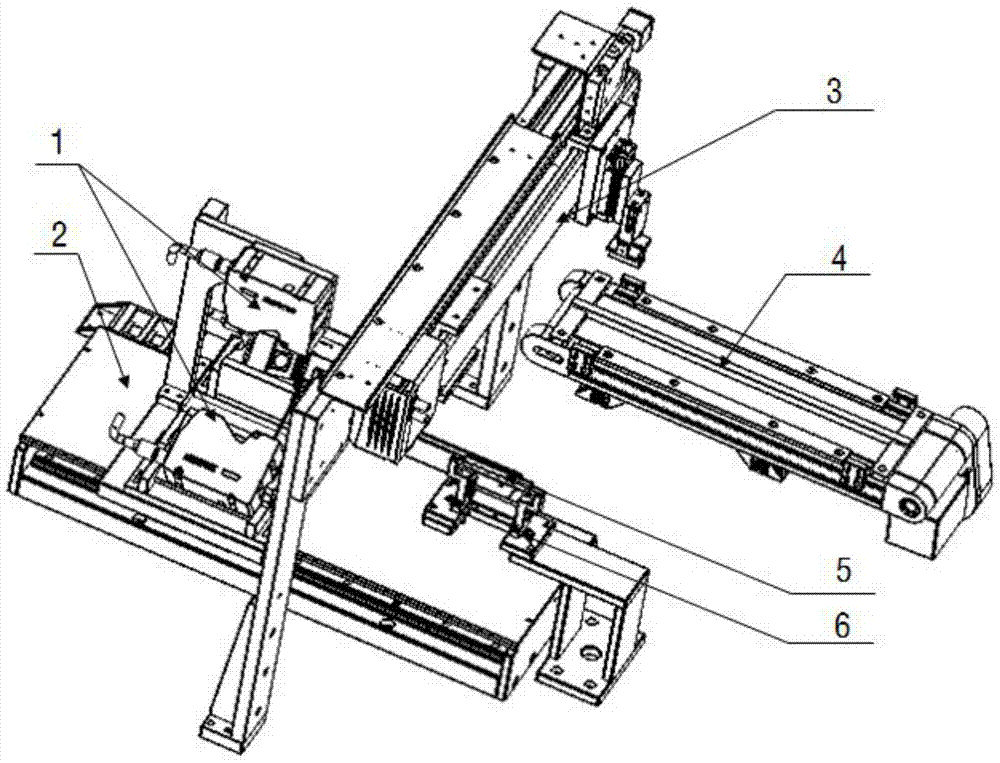

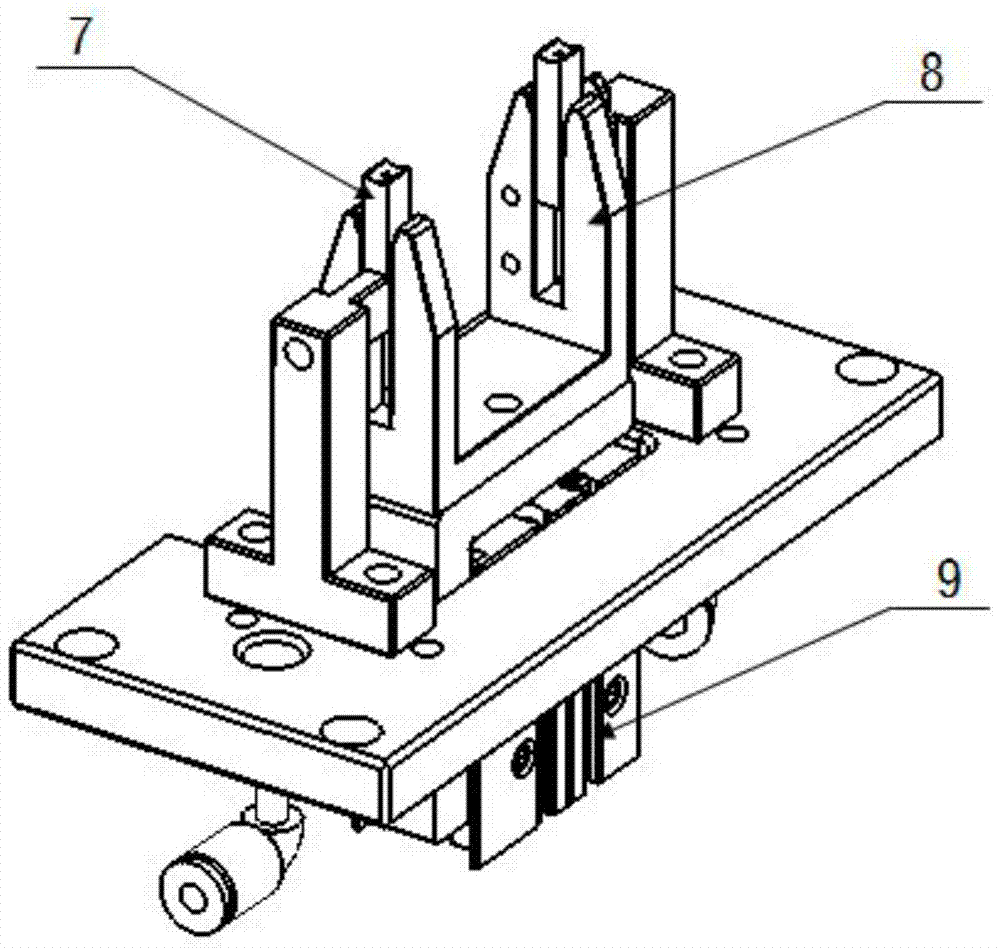

[0036] Such as figure 1 As shown, the full-surface three-dimensional measuring device for complex columnar workpieces of the present invention includes: a sensor assembly 1, a linear module 2, a loading fixture 6, a blanking mechanical arm 3, a blanking belt line 4, a calibration block and a controller; :

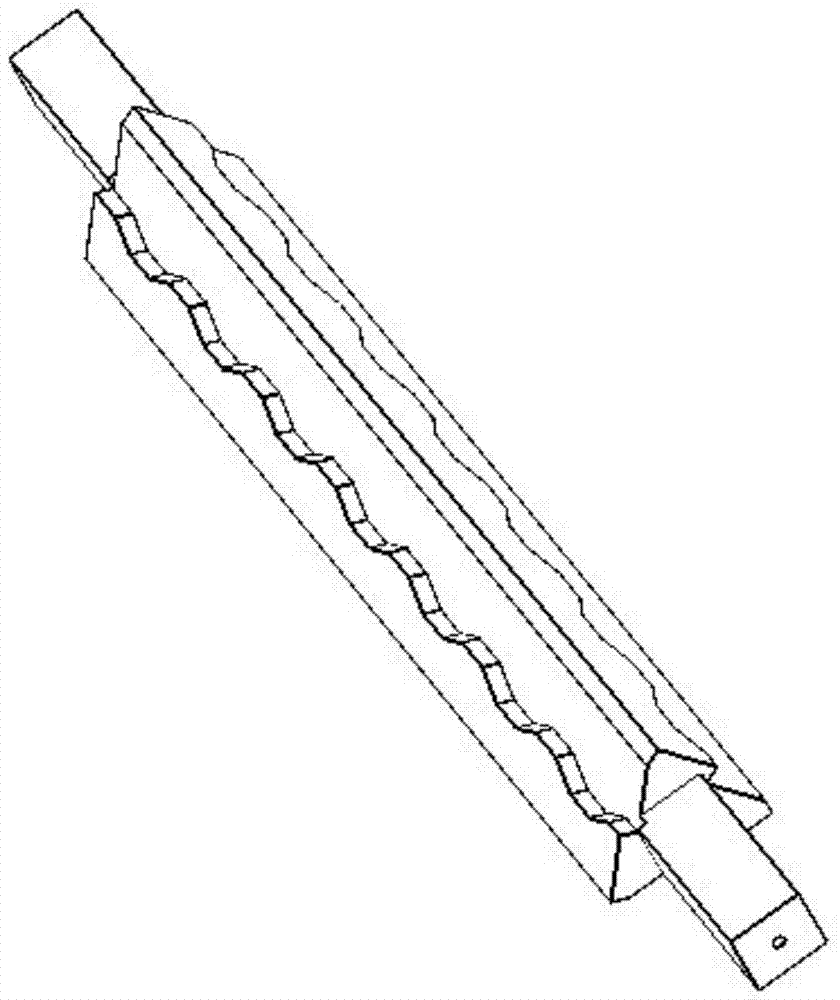

[0037] The sensor assembly 1 is composed of three line laser displacement sensors. The three sensors are not on the same plane. When installing, ensure that the distance between the sensor laser line and the 5 axis of the measured workpiece is about 4mm, and the three sensors are installed at an angle of 120 degrees to each other. .

[0038] The linear module 2 is composed of a linear motor and a bracket, and the sensor combination is fixed on the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com