Ultralow-emission MGGH energy conservation and environmental protection equipment and method for thermal power plant

An energy-saving and environmental protection technology for thermal power plants, applied in lighting and heating equipment, feed water heaters, preheating, etc., to achieve the effects of reducing flue gas emissions, reducing social and economic benefits, and avoiding low-temperature corrosion of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

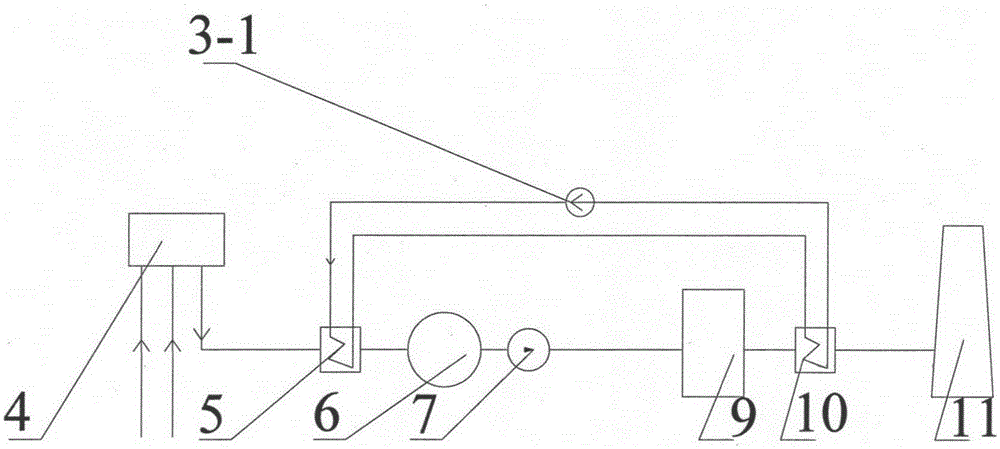

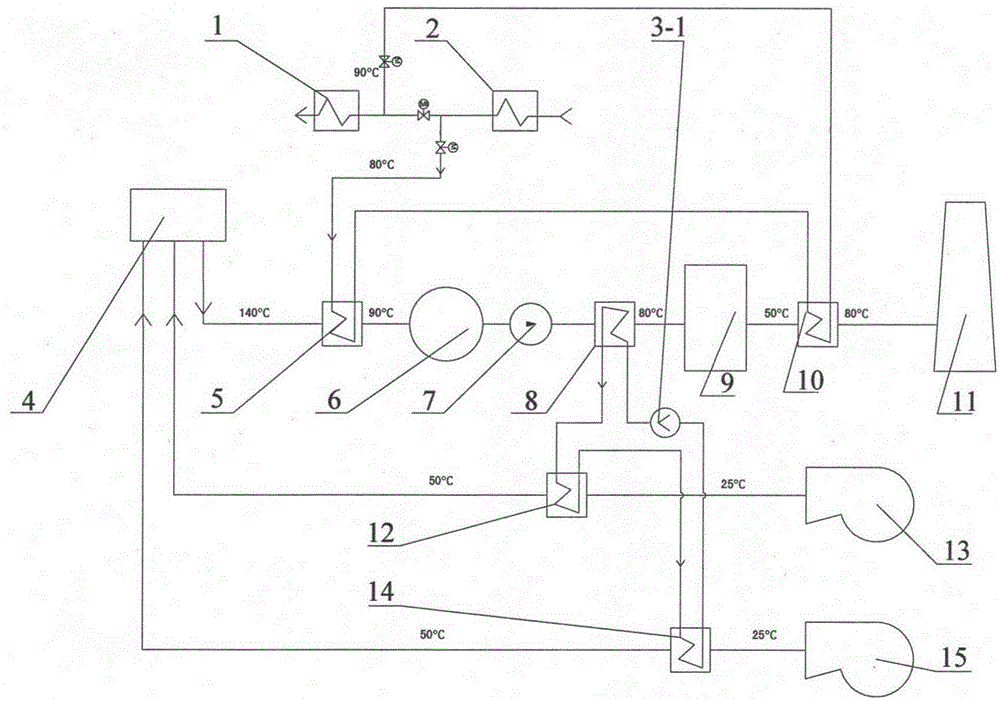

[0051] For example, a 1000MW boiler in a power plant, when the unit is operating at 0°C in winter, for figure 2 For the system shown, the temperature rise of the air heater is required to be 60°C; when the ambient temperature is 35°C, the temperature rise of the air heater is required to be 25°C. Low-temperature economizer 8 is not equal to the heating power of the air heater, and the system cannot be balanced. The result of the actual operation is that the air temperature at the outlet of the heater does not reach 60°C, and may be as low as 30°C. When the air temperature at the inlet of the boiler air preheater 4 decreases, the temperature of the flue gas at the outlet of the boiler air preheater 4 will also decrease accordingly , possibly to 100°C, if the gas temperature at the inlet of the electric precipitator 6 is still required to be 90°C, the temperature drop of the flue gas in the high-temperature radiator 5 of the original flue gas is only 10°C, and the thermal power...

Embodiment 2

[0056] For example, a 1000MW boiler in a power plant, when the unit operates at 35°C in summer, for figure 2 For the system shown, a heater temperature rise of 15°C is required. Low-temperature economizer 8 is not equal to the heating power of the air heater, and the system cannot be balanced. The result of actual operation is that the air temperature at the outlet of the heater exceeds 50°C and reaches 60°C. When the air temperature at the inlet of the boiler air preheater 4 increases, the flue gas temperature at the outlet of the boiler air preheater 4 will also increase correspondingly, possibly to 95 ℃, not meeting the design expectations.

[0057] but for image 3 For the system shown, when the ambient temperature is 35°C, the temperature of the air heater is required to rise by 15°C. The thermal power of the low-temperature economizer 8 and the air heater is naturally balanced by means of the condensate system. The result of the actual operation is that the outlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com