Automatic control method of plunger gas-lift liquid drainage production of oil-gas well

An oil and gas well and plunger technology, which is applied in the field of automatic control of the production of oil and gas well plunger gas lift and drainage, can solve the problems of limited application area, incompatibility between plunger gas lift drainage and oil and gas wells, etc. management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

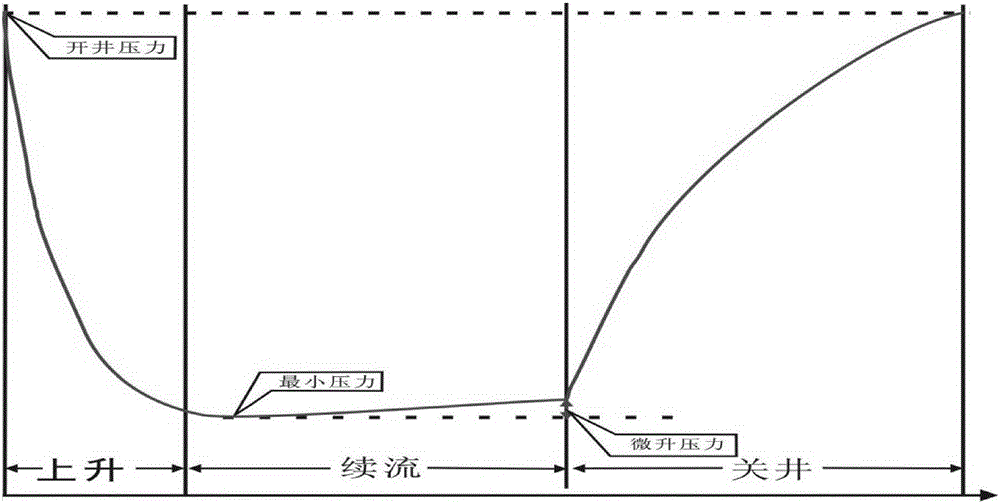

[0020] In order to overcome the problem that the existing plunger gas lift drainage is not closely combined with the actual liquid accumulation of oil and gas wells and has limited application, this embodiment provides an automatic control method for the production of oil and gas well plunger gas lift drainage, including Follow the steps below:

[0021] 1) Open the well, then lower the buffer holder and plunger into the oil and gas well tubing sequentially, connect the blowout preventer at the top of the wellhead Christmas tree or the wellhead Christmas tree, and the plunger is between the buffer holder and the blowout preventer At the same time, a pneumatic membrane valve is installed between the surface pipeline and the blowout preventer to control the switch of the oil and gas well. The pneumatic membrane valve is connected to the plunger controller by the wire, and the plunger controller realizes the operation of the oil and gas well switch by controlling the switch of the ...

Embodiment 2

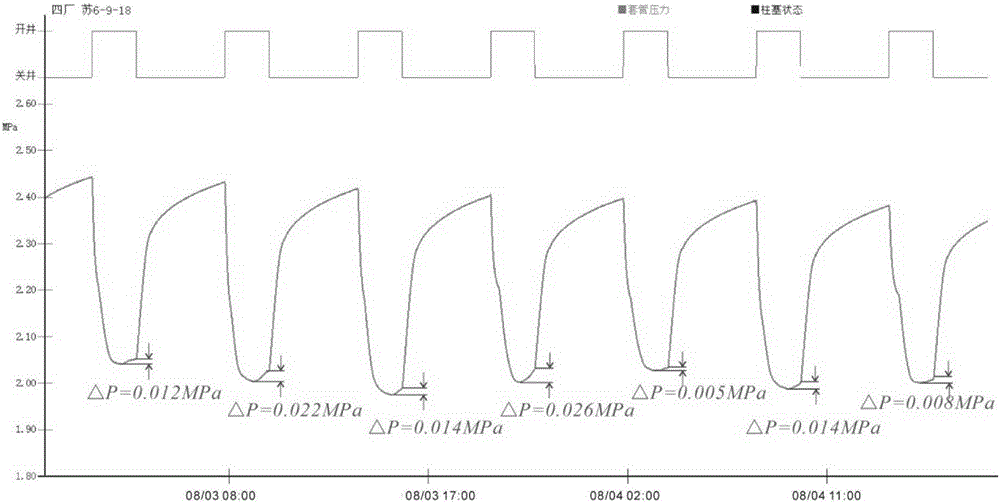

[0033] On the basis of Example 1, in this embodiment, by observing the pressure micro-rise value at the time of shutting down the well, when the plunger controller is set to the pressure micro-rise optimization mode, the opening pressure is 2.4MPa, and the micro-rise pressure is set to 0.015MPa.

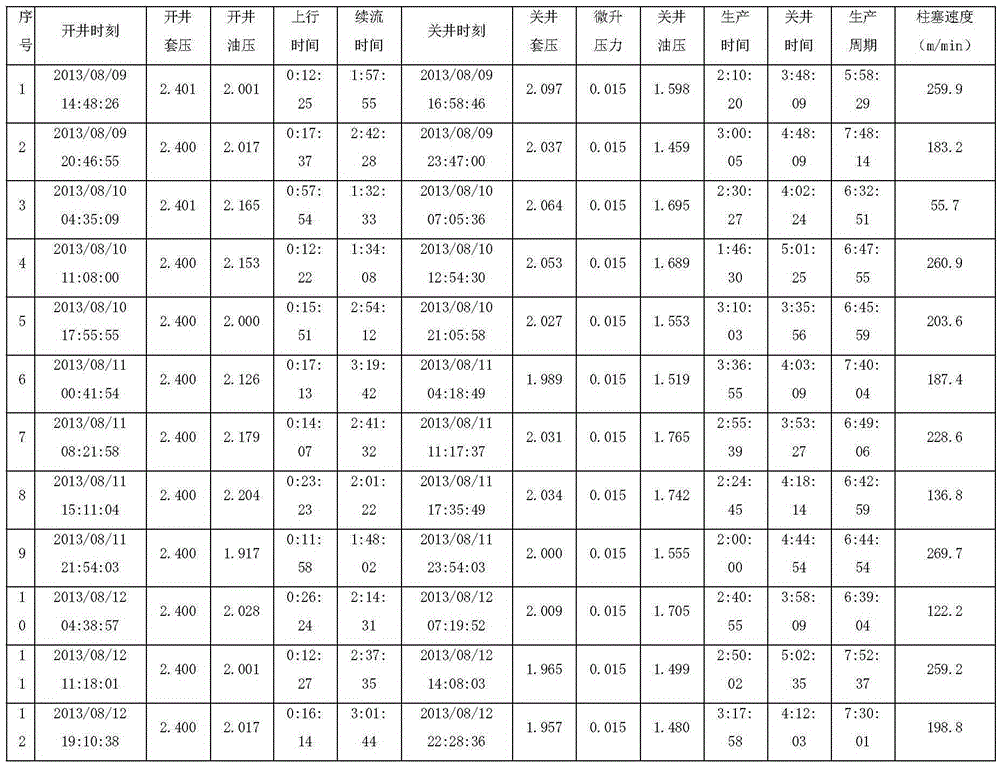

[0034] After the setting is completed, it will start to run, and after the plunger gas lift control system has been in operation for 3 days, export the production report data stored in the plunger controller, as shown in Table 1.

[0035] Table 1:

[0036]

[0037] It can be seen from Table 1 that the casing pressure at the start-up time is 2.4MPa, meeting the preset well-opening conditions; the casing pressure slight rise at the time of well-shut-in is 0.015MPa, meeting the preset well-shut-in conditions. In this mode, the controller automatically adjusts the opening and closing time according to the change of casing pressure, and the production system is in the state of automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com