A deceleration clutch bearing installation structure

A deceleration clutch and installation structure technology, applied in the field of washing machines, can solve the problems of unfavorable manufacturing and installation, large volume, high cost, etc., and achieve the effects of ensuring stability and reliability, broad market promotion prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

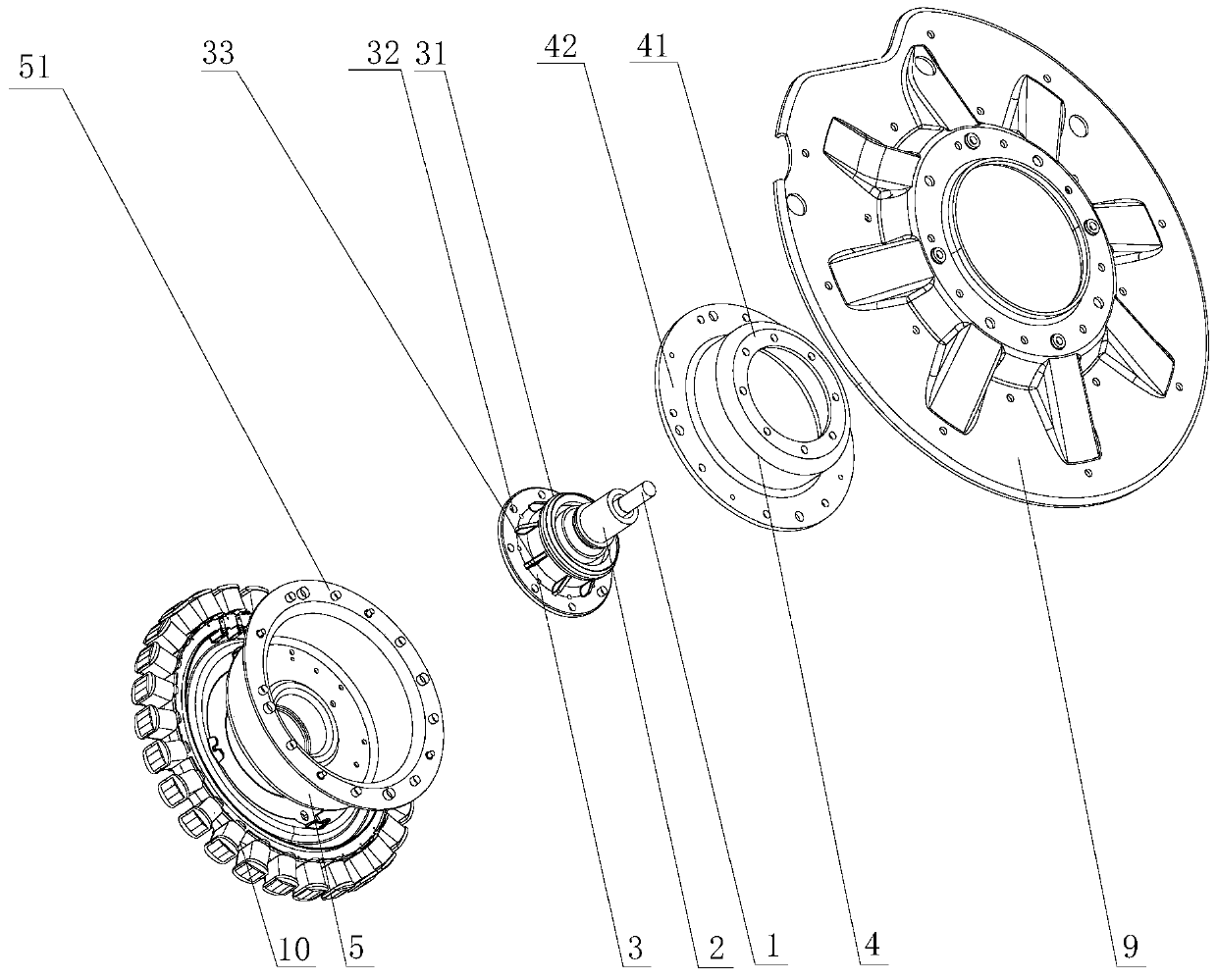

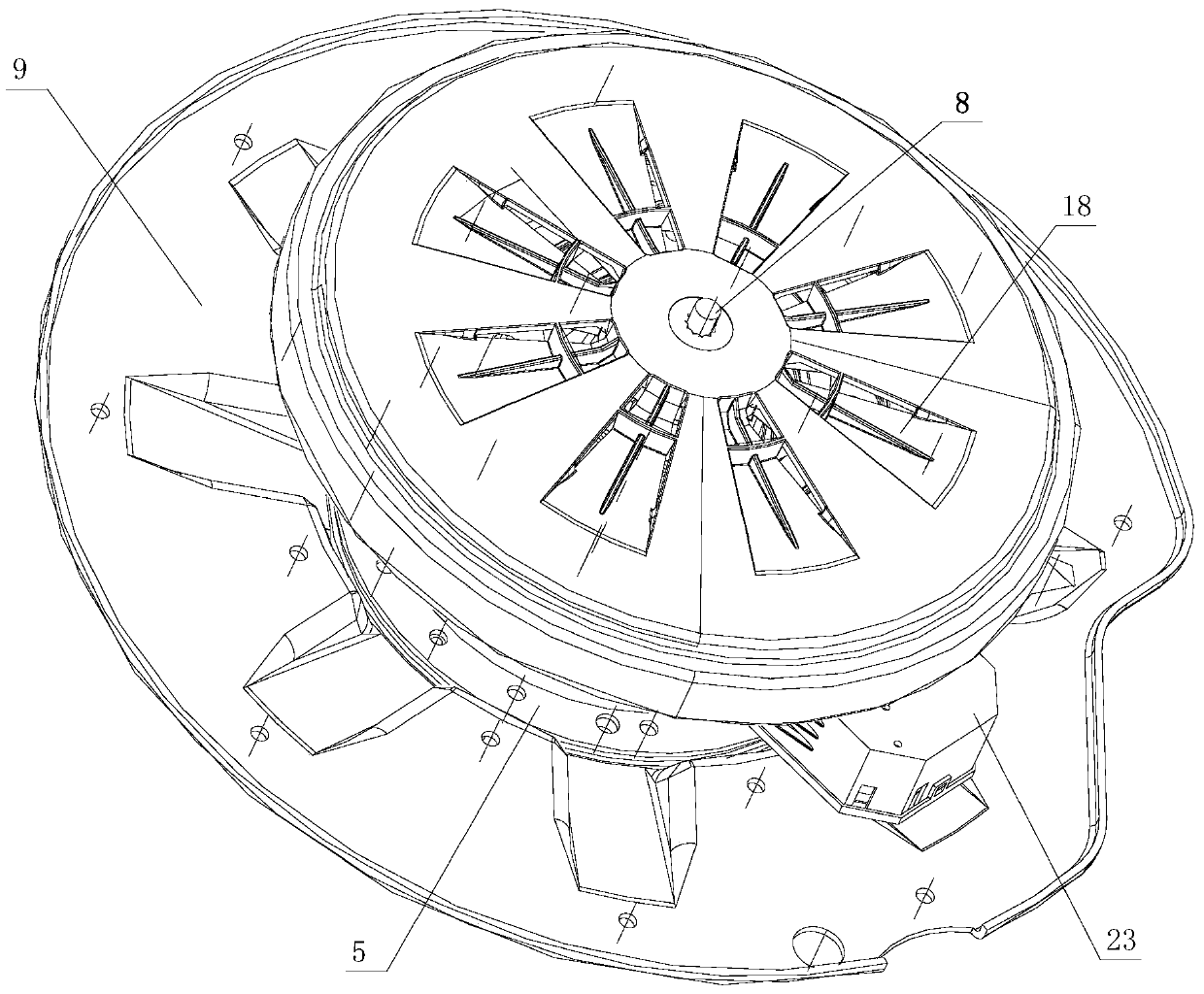

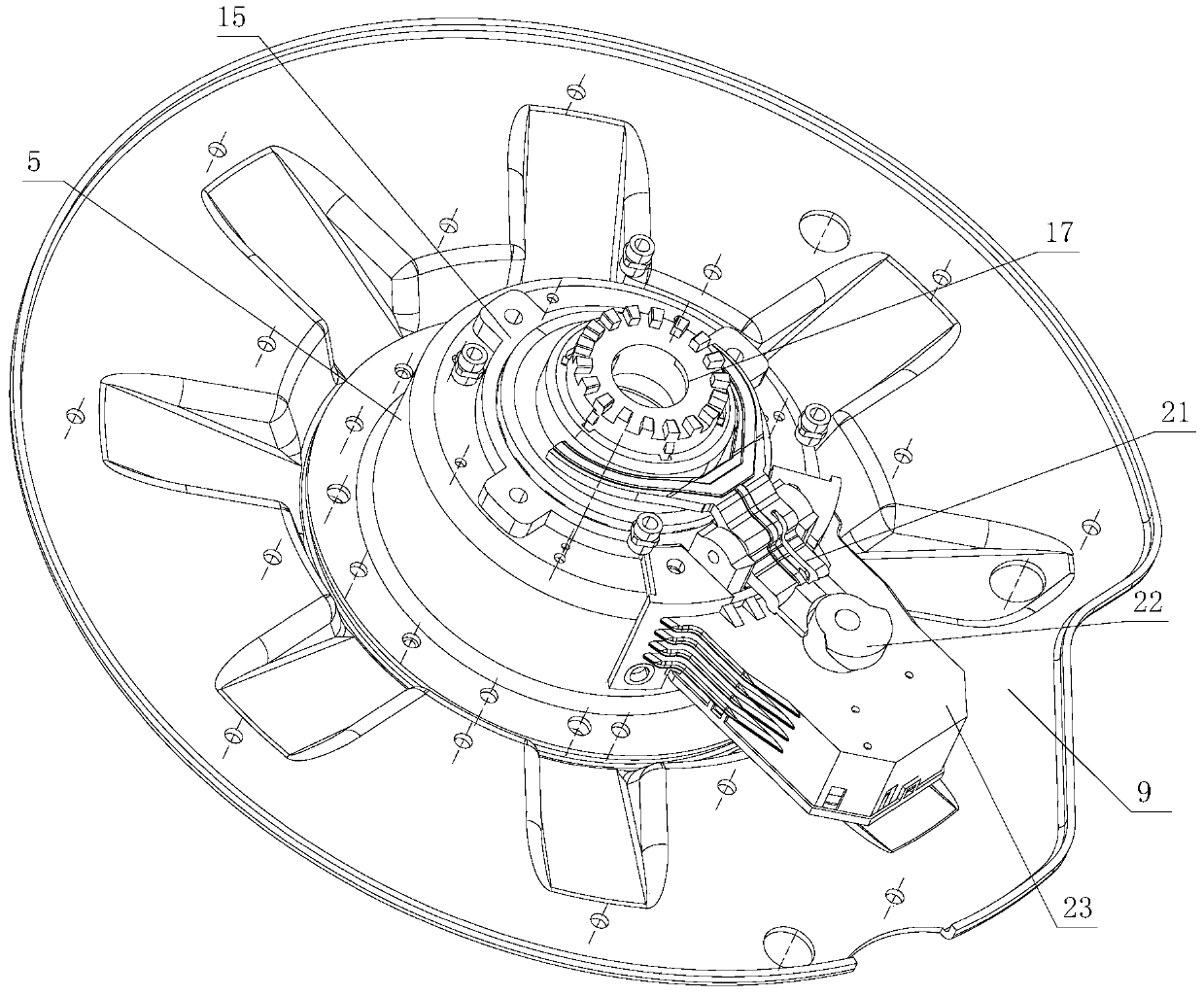

[0057] Such as Figure 3-5 As shown, the lower end of the lower end cover 5 of the present invention is provided with a clutch mechanism, and the clutch mechanism includes an upper fixed plate 15, a clutch sleeve 17 that can slide up and down and a lower dehydration plate 19, and the clutch sleeve 17 slides up and down and is respectively fixed with the upper The disc 15 and the lower dehydration disc 19 are meshed and connected to realize the conversion of washing and dehydration working conditions; the upper fixed disc 15 and the stator 10 of the motor are fixedly connected to the lower end surface of the lower end cover 5 respectively, and the stator 10 is connected to the The lower end cover 5 is fixedly connected, and the connecting piece 24 is an independent component.

[0058] The clutch device of the present invention is mainly used for large-capacity washing machines, and the capacity of the large-capacity washing machine of the present invention is above 15-20 kg, so...

Embodiment 2

[0069] The clutch device of the present invention is driven by the clutch driving device, and the clutch driving device drives the clutch sleeve 17 to move up and down to realize the clutch. Such as Figure 2-6 As shown, the clutch driving device of the present invention includes a driving motor 25 , a driving wheel 22 and a fork lever 21 . The shift fork lever 21 is a lever structure, the middle part is provided with a fixed fulcrum, the head is a shift fork 211, and the tail is a driving end 212 supported on the driving wheel 22. A boss 171 is provided on the outer circumference of the clutch sleeve 17, and a return spring 16 is provided between the upper surface of the boss 171 and the lower end cover 5 of the casing to provide a sliding force to the clutch sleeve 17; the lower surface of the boss 171 and the shift fork The head of the rod 21 is in contact with the shift fork 211 , and the shift fork rod 21 provides a variable lifting force for the clutch sleeve 17 . The ...

Embodiment 3

[0071] Such as Figure 3 to Figure 8 As shown, a deceleration clutch clutch driving device described in this embodiment includes a driving motor 25, a driving wheel 22 and a shift fork lever 21, and the driving wheel 22 is installed on the motor shaft of the driving motor 25, and the circumference of the driving wheel 22 is provided with supports The supporting surface has a height difference in the axial direction. The shift fork lever 21 is a lever structure with a fixed fulcrum in the middle. The head of the shift fork lever 21 is a shift fork 211. The shift fork 211 is located below the clutch sleeve 17, and the return spring 20 together to control the up and down movement of the clutch sleeve 17, the tail of the shift fork lever 21 is the driving end 212, and the driving end 212 is provided with a sliding contact surface, which is slidably matched with the supporting surface; the drive motor 25 drives the driving wheel 22 to rotate, and the tail of the shift fork lever 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com