Hoisting machine for wheeled automobiles

A truck crane and wheeled technology, applied in the field of transportation, can solve the problems of limited trailer width, high driver requirements, hidden safety hazards, etc., and achieve the effects of improving work efficiency, simplifying mechanical structure, and reducing risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

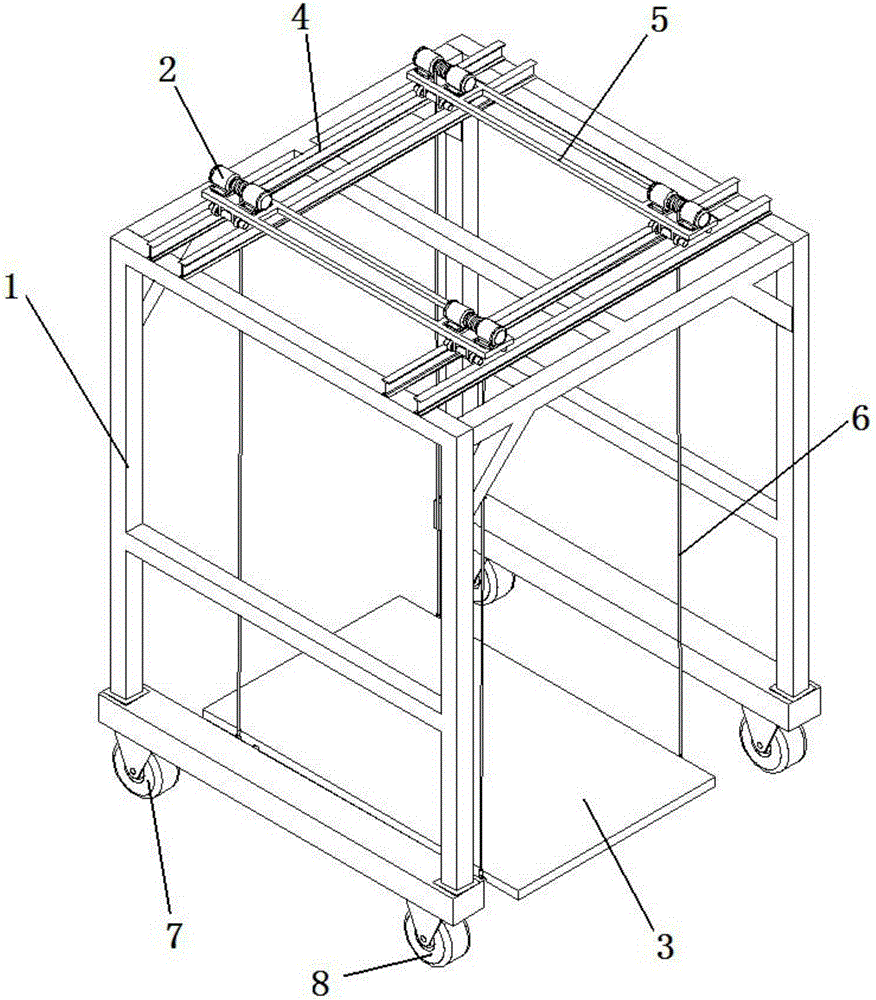

[0013] A wheeled car hoisting machine, comprising a portal wheel load-bearing frame 1, an electric hoist 2, a supporting plate 3, a guide rail 4 and a mobile trolley 5, the specific structure and connection relationship are as follows:

[0014] Two guide rails 4 are installed in parallel on the gantry pulley load-bearing frame 1, the guide rail 4 is perpendicular to the advancing direction of the gantry pulley load-bearing frame 1, the moving trolley 5 is installed on the two guide rails 4, and the four electric hoists 2 are respectively fixed on the moving The four corners of the dolly 5 and the ends of the wire rope 6 of the electric hoist are respectively fixed on the four corners of the supporting plate 3 .

[0015] The steering wheel 7 is installed at the front end of the portal type pulley load-bearing frame 1, and the driving wheel 8 is installed at the rear end.

[0016] During operation, the electric hoist 2 puts the supporting plate 3 on the ground through the wire r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com