Assembling machine with spring prepressing devices and for emulsion pump or atomizing pump

A technology for spray pumps and assembly machines, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., and can solve problems that affect the assembly process, inconsistent heights, and spring length errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

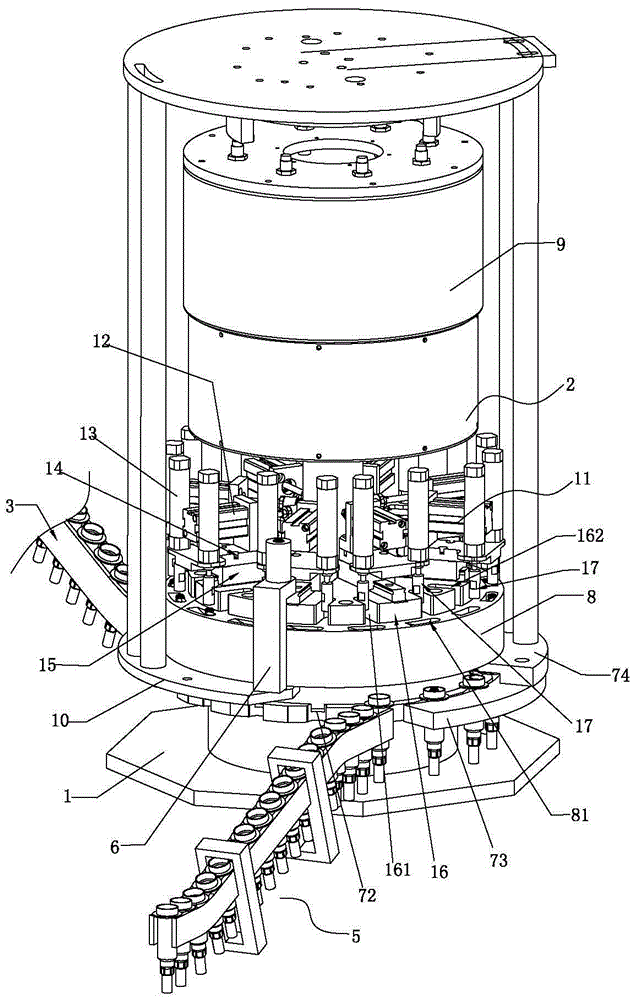

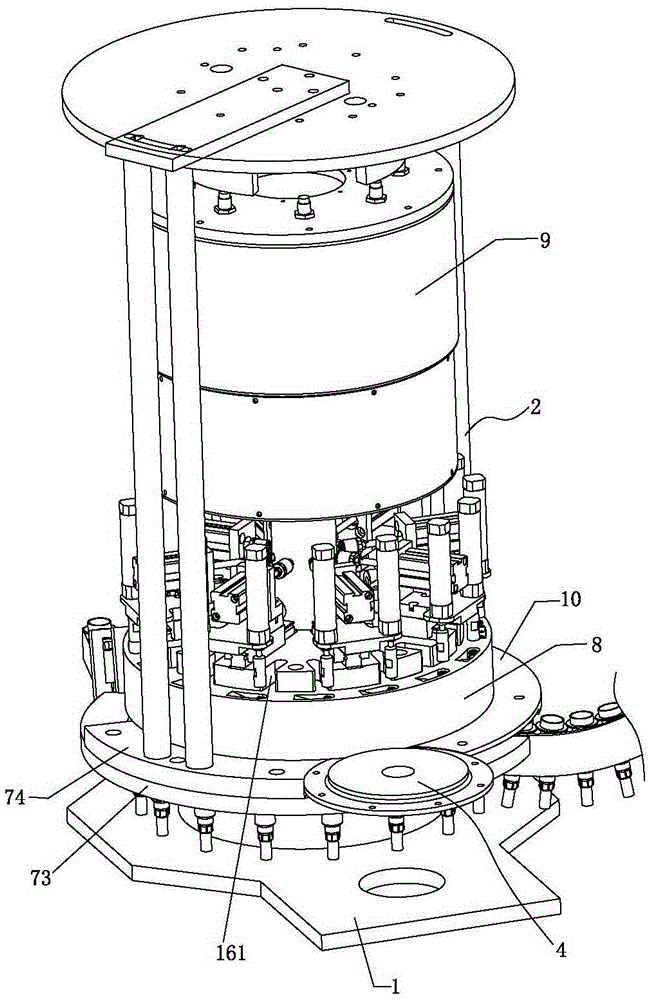

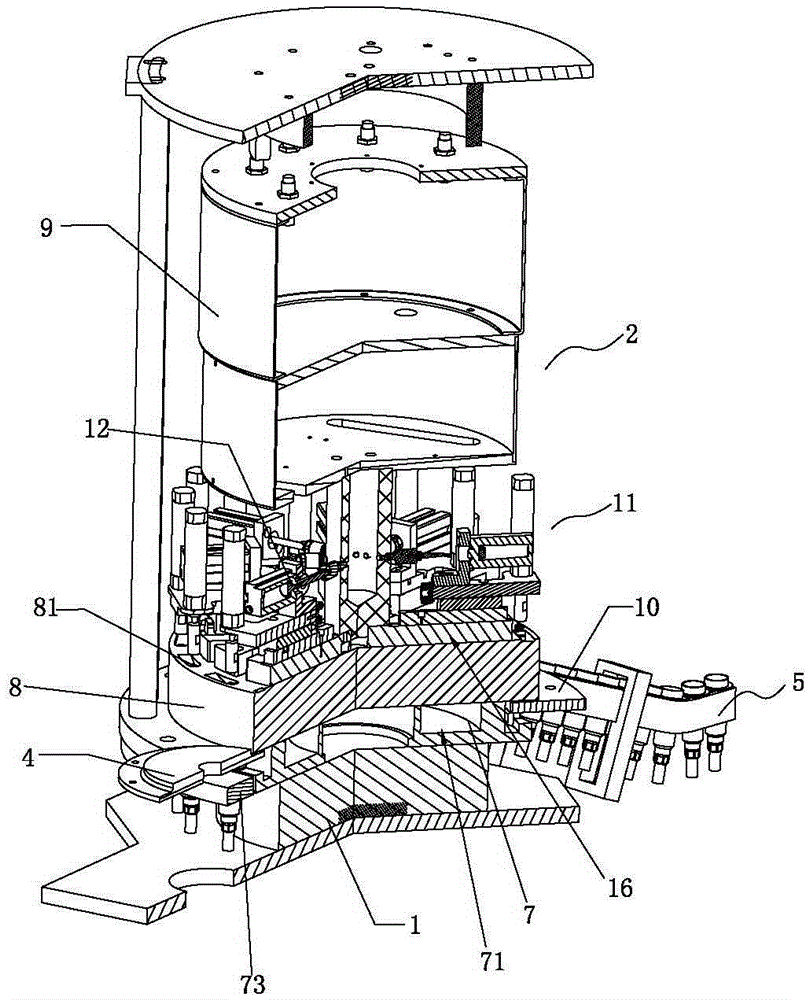

[0018] Such as figure 1 As shown, an assembly machine for a lotion or spray pump with a spring preloading device, including a base 1, a host 2, a body supply device 3, a glass bulb loading device 4, a body output mechanism 5, a spring supply mechanism 6 and a body carrying device 7. The host 2 is set on the base 1 and rotates relative to the base 1. The main body supply device 3 and the glass ball loading device 4 cooperate with the host 1, and the spring supply mechanism 6 is fixed on the base 1;

[0019] The main engine 2 includes a bottom disc 8, a top rotating body 9 and an arc-shaped spring support plate 10, and several axial spring guide holes 81 are distributed on the bottom disc 8; the spring supply mechanism 6 and the arc-shaped spring support plate 10. One end fits; the body bearing device 7 includes a rotating seat 71, an annular bearing plate 72, an arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com