Preparation method of thin polyvinyl alcohol polarizing film

A technology of polyvinyl alcohol and polarizing film, applied in the direction of optics, polarizing elements, optical elements, etc., can solve problems such as defects, difficult peeling, curling, etc., achieve uniform strength characteristics, avoid stress unevenness, polarization and light transmittance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

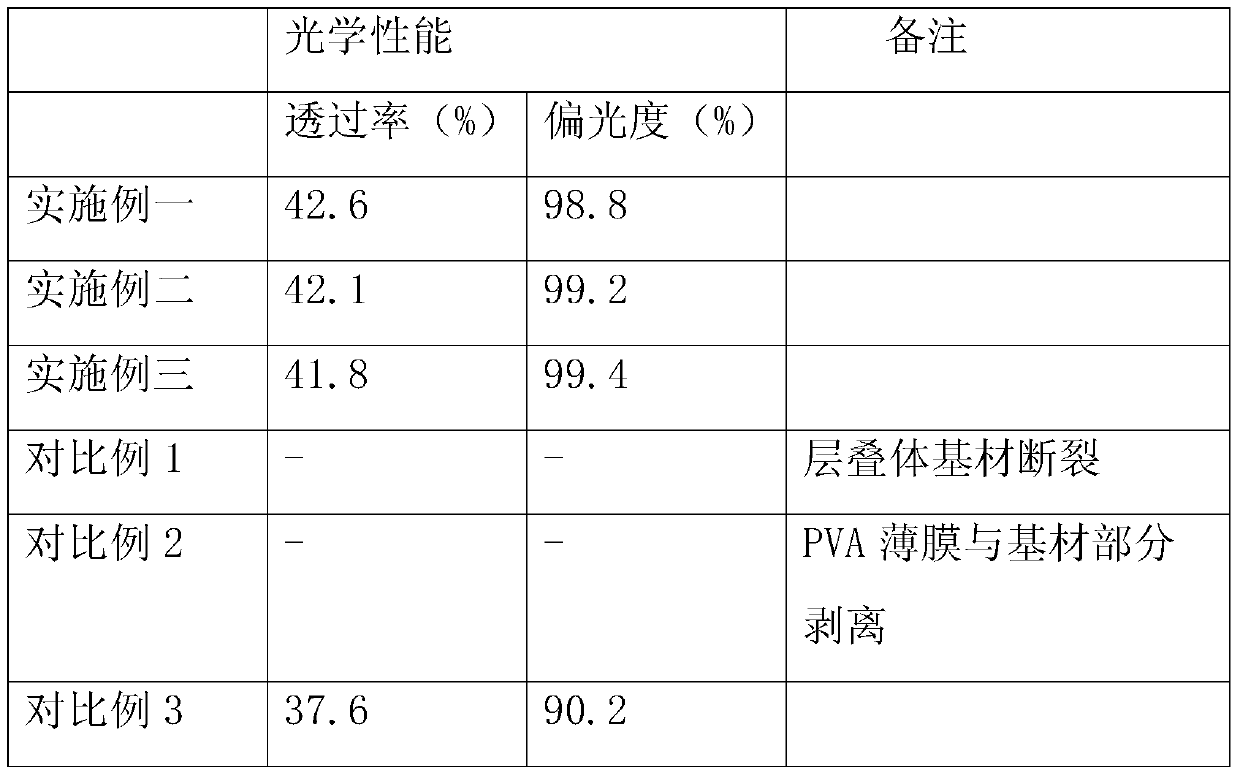

Examples

preparation example Construction

[0020] The preparation method of thin polyvinyl alcohol polarizing film of the present invention comprises the following steps:

[0021] a. Preheating the thermoplastic resin substrate;

[0022] b. Form a polyvinyl alcohol layer on a thermoplastic resin substrate and dry it to obtain a laminate; the formation of the laminate can adopt any existing suitable method, such as casting coating, wet film making, melt extrusion, casting film etc., preferably formed by coating a coating liquid containing a PVA-based resin on a thermoplastic substrate; the coating liquid is a solution obtained by dissolving the above-mentioned PVA-based resin in a solvent, and examples of the solvent include dimethyl sulfoxide , dimethylformamide, dimethylacetamide, ethylene glycol, propylene glycol, trimethylolpropane, glycerol, water, etc., preferably water; the polyvinyl alcohol (PVA) resin concentration of the solution is preferably relative to 100 parts by weight of the solution 10-30 parts by wei...

Embodiment 1

[0036] The preparation method of the thin polyvinyl alcohol polarizing film of the present embodiment comprises the following steps:

[0037] a. Preheating the thermoplastic resin substrate, the thermoplastic resin substrate is composed of linear polyphenylene sulfide resin with a crystallinity of 10%, the preheating temperature is 40° C., and the thickness of the thermoplastic substrate is 30 μm;

[0038] b. A polyvinyl alcohol layer is formed by coating on a thermoplastic resin substrate and dried at a temperature of 70°C to obtain a laminate. The surface of the thermoplastic resin substrate used to form the laminate is polished, and the surface roughness is 0.05 μm The coating liquid is water, and the solution concentration is 10 parts of polyvinyl alcohol (PVA) in 100 parts by weight of the solution, and plasticizer ethylene glycol is also added in the solution; the degree of polymerization of polyvinyl alcohol is 1500, and the degree of saponification is 99mol%; The thick...

Embodiment 2

[0042] The preparation method of the thin polyvinyl alcohol polarizing film of the present embodiment comprises the following steps:

[0043] Include the following steps:

[0044] a. Preheating the thermoplastic resin substrate, the thermoplastic resin substrate is composed of linear polyphenylene sulfide resin with a crystallinity of 8%, the preheating temperature is 60° C., and the thickness of the thermoplastic substrate is 150 μm;

[0045] b. A polyvinyl alcohol layer is formed by coating on a thermoplastic resin substrate and dried at a temperature of 90°C to obtain a laminate. The surface of the thermoplastic resin substrate used to form the laminate is polished, and the surface roughness is 0.03 μm The coating solution is water, and the concentration of the solution is 20 parts of polyvinyl alcohol (PVA) in 100 parts by weight of the solution, and plasticizer glycerin is also added in the solution; the degree of polymerization of polyvinyl alcohol is 3800, and the degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com