Elevator landing sill

A technology of floor doors and sills, applied in elevators, transportation and packaging in buildings, etc., can solve the problems of easy damage, poor flexibility, large load, etc., to improve the ability to bear the load and increase the force area. Great, increase durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

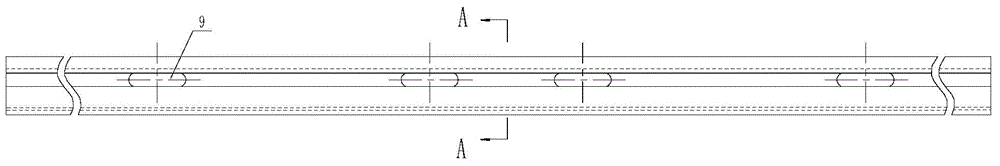

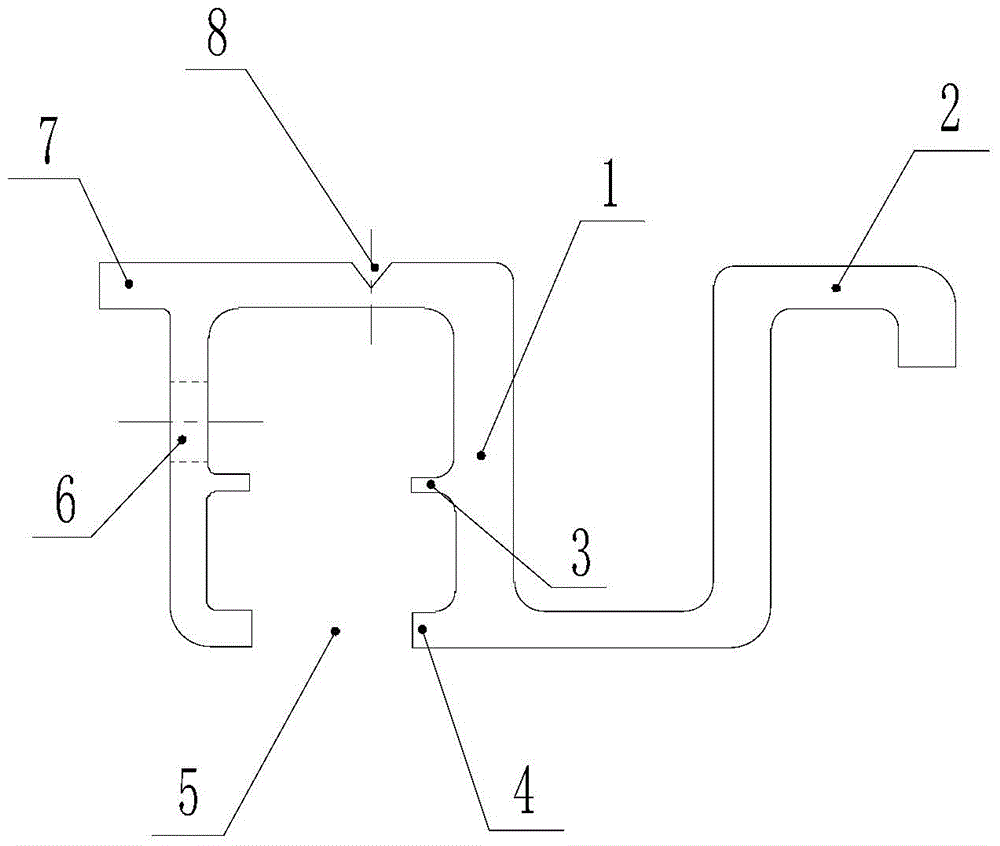

[0018] Examples such as figure 1 and figure 2 As shown, a floor door sill of an elevator includes a base plate, a right drag block, a reinforcing rib, a hook, ash leakage groove, a cylindrical hole, a lower left drag block, an anti-skid groove and a waist hole; the base plate is "U" The right dragging block is vertically connected to the upper end of the right side wall of the substrate, the right dragging block is an "L" shaped structure, the left dragging block is vertically connected to the upper end of the left side wall of the substrate, and the top surface of the left dragging block is set There is an anti-skid groove, an ash leakage groove is provided between the base plate and the left drag block, the hook is arranged at the bottom of the ash leakage groove, a reinforcing rib is provided on the left outer wall of the base plate near the middle, and the base plate Several waist-shaped holes are arranged on the bottom surface, and cylindrical holes are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com