Use method of tapping clamp

A fixture and tap technology, applied in the field of machining, can solve the problems of easily broken taps, difficult threads, and waste products, and achieve the effects of avoiding waste products, good processing quality and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

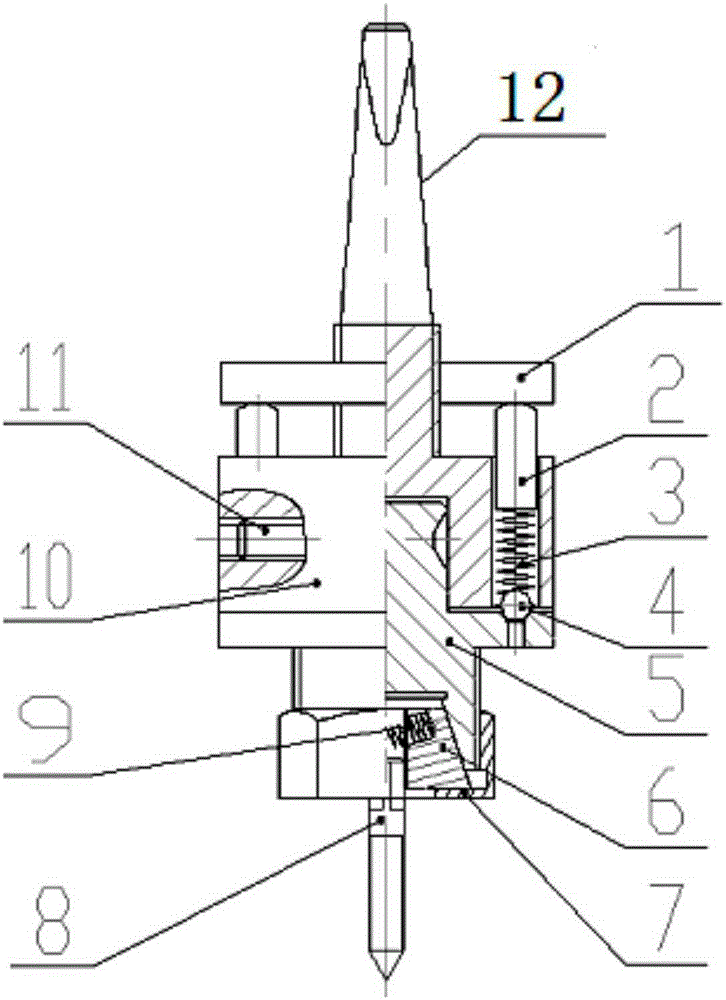

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0021] The using method of tapping fixture of the present invention, as figure 1 As shown in , the tapping machine oil includes a fixture body 1, the upper end of the fixture body 1 is installed on the drilling machine through the mounting column 12, the tap 8 is connected under the fixture body 1 through the clutch 5, and the fixture body 1 is also provided with a control clutch 5 clutch Torque adjustment device. By adjusting the adjusting device to control the size of the clutch torque of the clutch 5, to adapt to tap the threaded holes of different diameters.

[0022] The adjustment device includes an adjustment nut 1 arranged above the fixture body 1 and a pin 2 arranged on the fixture body 1. The lower end of the adjustment nut 1 is crimped on the pin 2, and a supporting adjustment spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com