Vertical lifting device of roller mill used for processing steel slag

A vertical lift, roller mill technology, applied in grain processing and other directions, can solve the problem of low grinding efficiency of roller mills, and achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

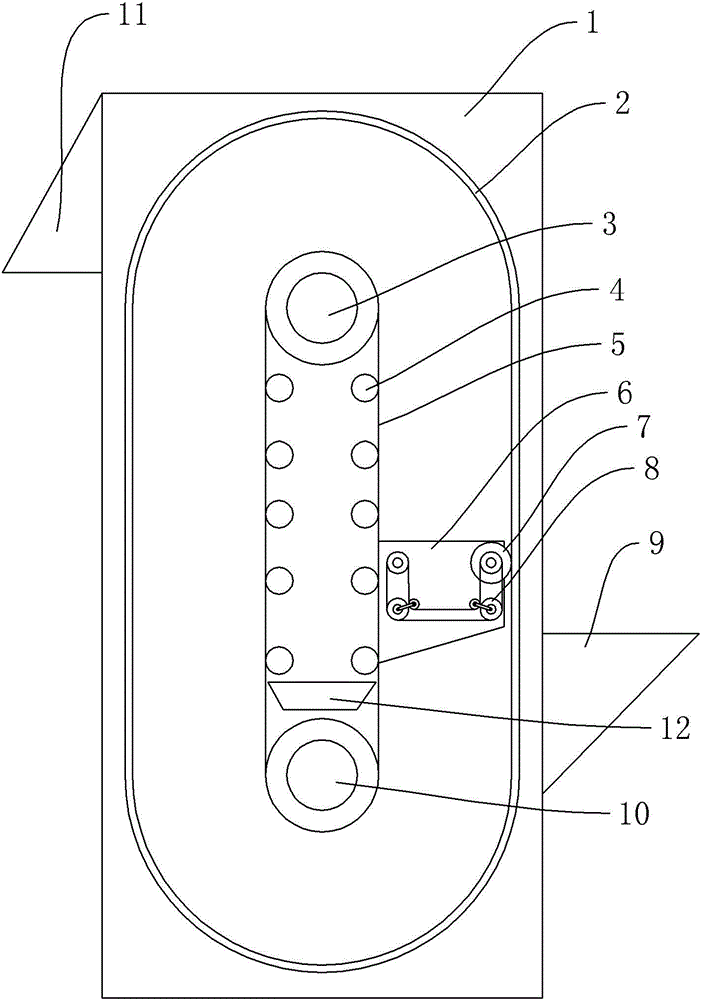

[0014] In the figure: housing 1, rack 2, direction changing roller 3, horizontal idler 4, first conveyor belt 5, conveying hopper 6, gear 7, sprocket 8, feeding hopper 9, driving roller 10, discharging hopper 11, Collection tank 12.

[0015] Such as figure 1 The shown vertical lifting device for a roller mill for processing steel slag includes a housing 1 , the lower right side of the housing 1 is provided with a feed inlet, and the upper left side of the housing 1 is provided with a first outlet. The housing 1 is provided with a motor outside, and the inner wall of the housing 1 is provided with a rack 2 . The casing 1 is provided with a driving drum 10 and a direction changing drum 3, and the driving drum 10 is connected with a motor. A number of horizontal rollers 4 are provided between the drive drum 10 and the direction changing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com