Black tea steaming system

A technology of steaming and black tea, which is applied in tea treatment before extraction, etc., which can solve problems such as uneven humidity, uniform stirring of tea leaves, and affecting fermentation quality, so as to achieve uniform steam contact with tea leaves, good humidity uniformity of tea leaves, and improve fermentation quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

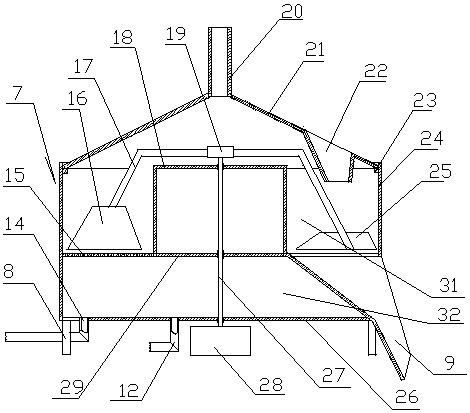

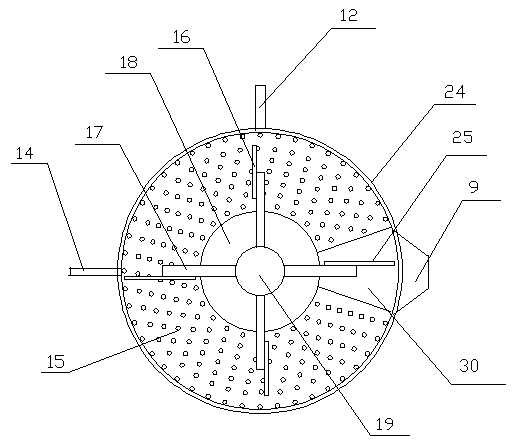

[0013] Embodiment 1: Black tea steaming system, including but not limited to controlling the raw material conveyor 2 by the controller 31, and a steamer is provided at the discharge end of the raw material conveyor 2. The steamer is a disc steamer 7. The disc steamer 7 can be suspended at the discharge end of the raw material conveyor 2 . Described disc steamer 7 comprises machine barrel 24, is provided with machine bottom 28 at the bottom of machine barrel 24, is provided with the machine cover 21 that takes out trachea 20 at the top of machine barrel 24, on machine cover 21, leans to the right A lower hopper 22 is provided, and the lower hopper 22 is socketed with the discharge hopper 6 of the conveyor 2, and is separated by a partition 29 in the middle of the inner cavity of the barrel 24. The lower part is a steam chamber 32, and the upper part is a mixing chamber 31. In the stirring chamber 31 There is a cylindrical cover 18 in the middle, and the cylindrical cover 18 an...

Embodiment 2

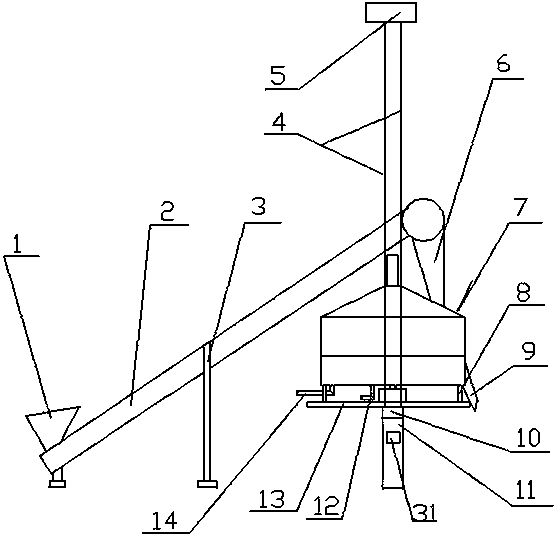

[0014] Embodiment 2: black tea steaming system, comprising raw material conveyor 2, described raw material conveyor 2 is provided with feed hopper 1, support frame 3 and discharge hopper 6, and is controlled by controller 31, in raw material conveyor 2 The discharge end is provided with a disc steamer 7, and the disc steamer 7 is suspended in the air, and can also be arranged on the ground through the supporting feet 8. Described disc steamer 7 comprises machine barrel 24, is provided with machine bottom 28 at the bottom of machine barrel 24, and is provided with machine cover 21 at the top of machine barrel 24. The top of the machine cover 21 is provided with an air outlet pipe 20 . On the right side of the machine cover 21, there is a lower hopper 22, the lower hopper 22 is socketed with the discharge hopper 6 of the conveyor 2, and the middle part of the inner cavity of the barrel 24 is separated by a partition 29, the lower part is the steam chamber 32, and the upper part ...

Embodiment 3

[0015] Embodiment 3: black tea steaming system, comprising a raw material conveyor 2, the raw material conveyor 2 is provided with a feed hopper 1, a support frame 3 and a discharge hopper 6, the number of support frames 3 is set according to needs, and generally the front and middle the last three. The raw material conveyor 2 is controlled by a controller 31 . A steamer is suspended at the discharge end of the raw material conveyor 2, and the steamer can be a drum steamer or a disc steamer 7, and the drum steamer or the disc steamer 7 can pass through the supporting legs 8 is arranged on the fixed plate 13. The following of the fixed plate 13 is provided with a beam 10, and one end of the beam 10 is fixed on the pillar 11, and the other end of the beam 10 connects the suspension rod 4, and the upper end of the suspension rod 4 is fixed on the crossbeam 5. Suspender 4 can be provided with 2, is fixed on the left and right sides of beam 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com