Selective cooling electrical cabinet

A selective, electrical cabinet technology, applied in the field of electrical cabinets, to achieve the effect of ensuring spraying accuracy, reliable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

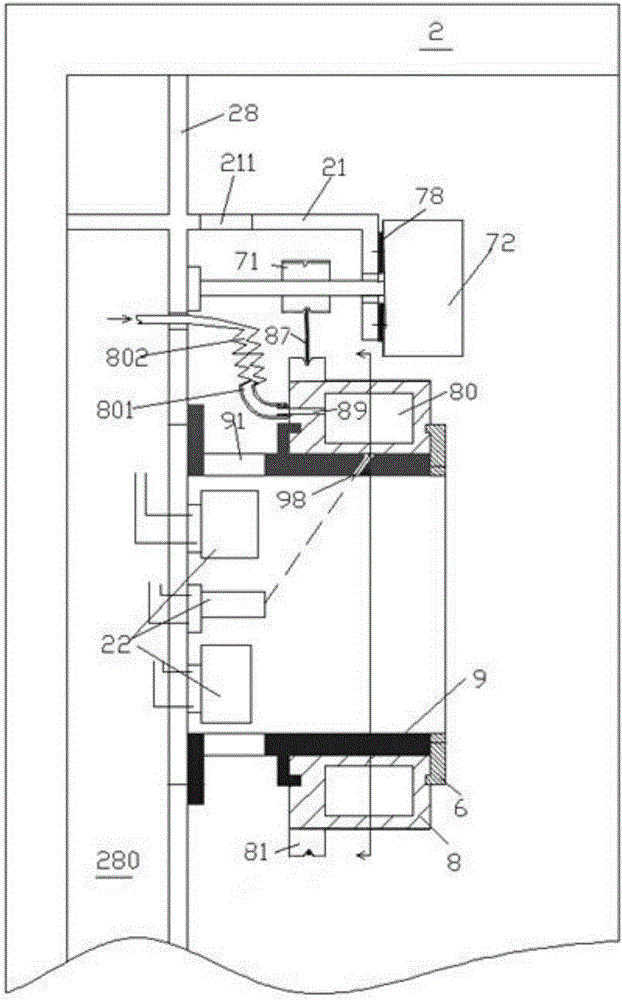

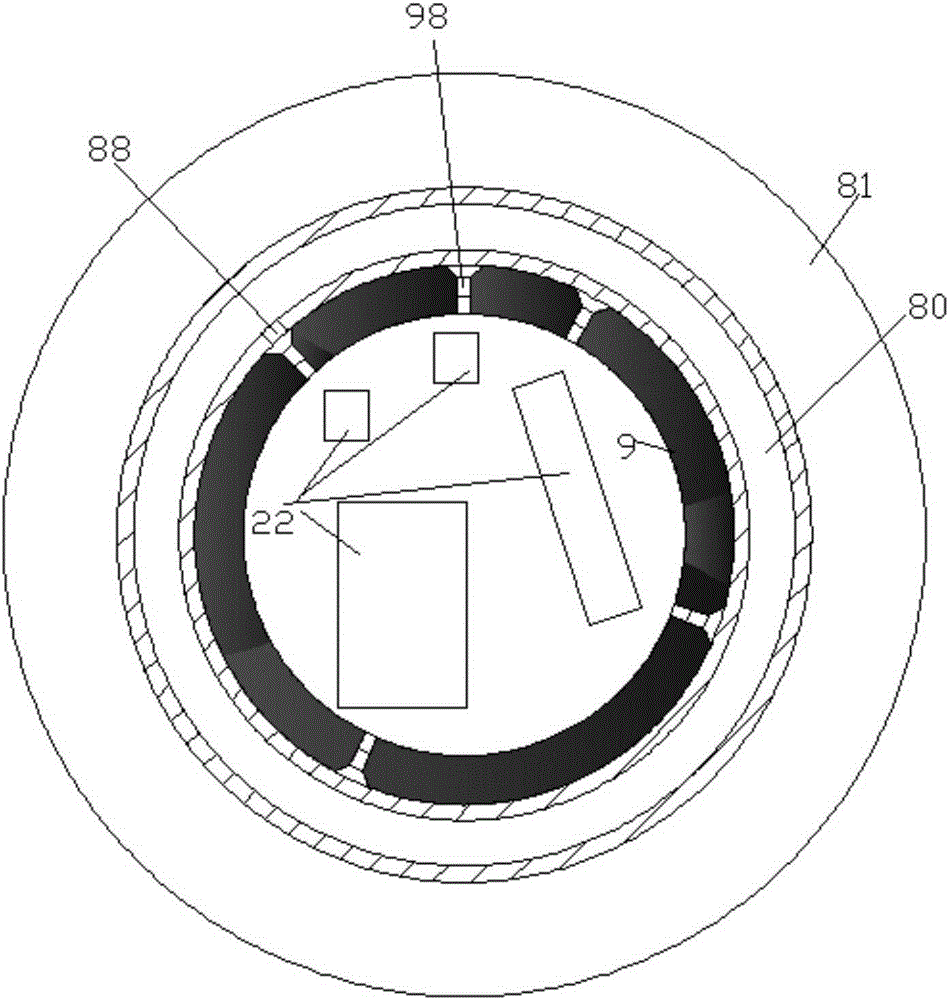

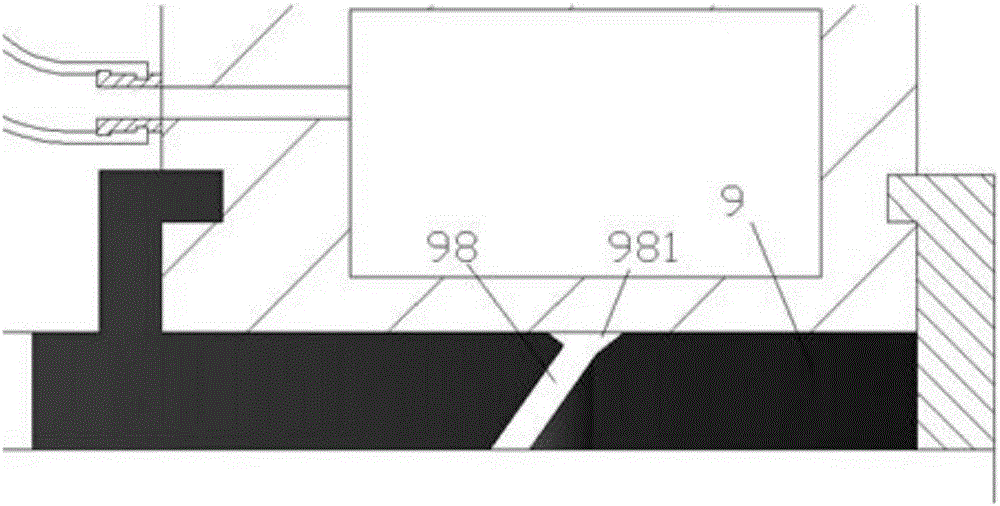

[0009] pass below Figure 1-3 The present invention will be described in detail.

[0010] An electrical cabinet with optional cooling, comprising a cabinet body 2, a mounting plate 28 fixed in the cabinet body 2 for installing electrical components, an electrical component 22 that is installed on the mounting plate 28 and needs to be cooled, and The local cooling device for cooling the electrical device that needs to be cooled, the local cooling device includes a fixed cooling device that is fixedly installed on the mounting plate 28, surrounds the electrical device that needs to be cooled, and has a ventilation opening 91 at the bottom. Bearing cylinder 9, the outer peripheral wall of the fixed bearing cylinder 9 is rotatably fitted with an air path distribution ring 8 with an annular cavity 80, wherein the top end of the fixed bearing cylinder 9 is fixedly provided with a detachable stop The retaining ring 6 is used to rotatably cooperate with the outer surface of the air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com