Automatic Pitch Adjustment Mechanism of Vertical Axis Hydrogenerator

A hydroelectric generator, vertical axis technology, applied in the direction of hydroelectric power generation, machine/engine, reaction engine, etc., can solve the problems of large wear of the brake pads, the hydroelectric generator no longer works, etc., to increase the movement resistance and increase the movement water. resistance, the effect of reducing the driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

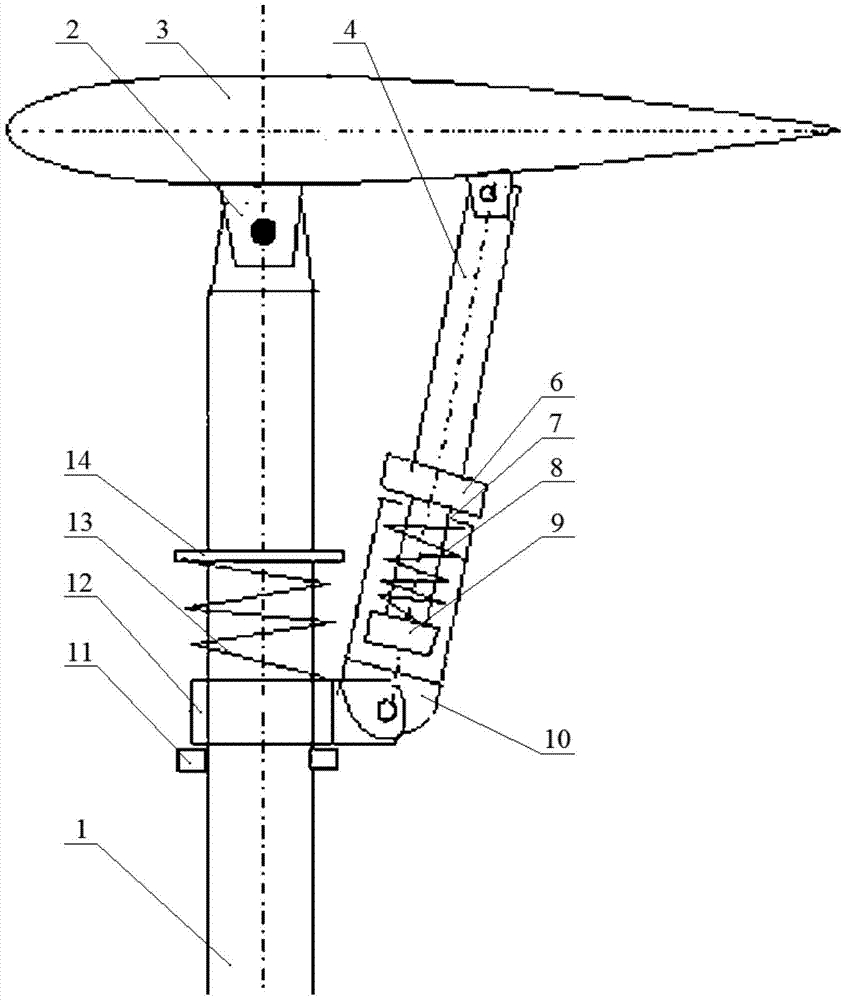

[0038] Such as figure 1 Shown is an automatic pitch-changing mechanism for a vertical-axis hydroelectric generator. The vertical-axis hydroelectric generator includes a main shaft, on which a rotating cylinder (not shown in the figure) is mounted to rotate, and a number of support rods 1 are fixed on the outer wall of the rotating cylinder. , blades 3 are rotated on each support rod, the length direction of the blades is parallel to the axial direction of the main shaft, and the automatic pitch mechanism includes:

[0039] Sliding sleeve 10, one end is hinged on the side wall of support rod 1, and the other end has a through hole 7;

[0040] One end of the speed limiting rod 4 is hinged on the blade 3, the other end passes through the through hole 7, extends into the sliding sleeve 10, and is slidably matched with the sliding sleeve, and the end of the speed limiting rod extending into the sliding sleeve has a first limit bit block 9;

[0041] The first pre-compression sprin...

Embodiment 2

[0047] Such as figure 2 Shown is an automatic pitch-changing mechanism for a vertical-axis hydroelectric generator. The vertical-axis hydroelectric generator includes a main shaft, on which a rotating cylinder (not shown in the figure) is mounted to rotate, and a number of support rods 1 are fixed on the outer wall of the rotating cylinder. , blades 3 are rotated on each support rod, the length direction of the blades is parallel to the axial direction of the main shaft, and the automatic pitch mechanism includes:

[0048] Two fixing rings are fixed on the side wall of the support rod 1 at intervals, and the one adjacent to the blade 3 is the first fixing ring 14, and the one away from the blade is the second fixing ring 11;

[0049] The slider 12 is sheathed on the support rod 1 and is located between two fixing rings, and the slider 12 is slidably matched with the support rod 1;

[0050] The second pre-compression spring 13 is sheathed on the support rod 1, and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com