Spliced type container house roof combined top plate

A container, splicing technology, applied in the direction of roof, roof covering, roof using flat/curved panels, etc., can solve the problems of high cost of steel plate, difficult to transport, etc., to achieve strong wind and rain resistance, not easy to loosen, Easy and fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

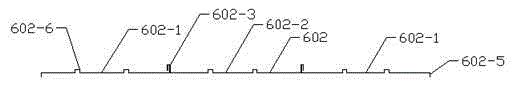

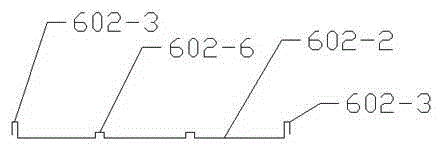

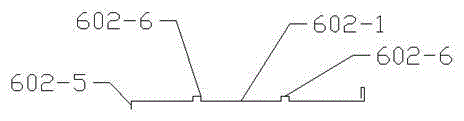

[0023] Please refer to the accompanying drawings, the spliced container house roof combination roof 602 provided by the present invention is formed by splicing three panels, which are two side roof roof panels 602-1 and a middle roof roof panel 602-2, and the middle roof roof panel 602-2 side edges have outwardly bent middle straps 602-3, and one side edge of the side roof top plate 602-1 has an inward edge that is compatible with the middle strap 602-3 of the edge of the middle roof roof 602-2. When splicing the bent side panels 602 - 4 , the panels of the middle roof roof 602 - 2 and the side roof panels 602 - 1 overlap each other, overlap each other, and are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com