Method for producing salts with a reduced water of crystallisation content

A technology of crystal water and moisture content, which is applied in the direction of alkali metal carbonate to change crystal water content, chemical instruments and methods, and types of dried products, etc., and can solve problems affecting drying speed and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

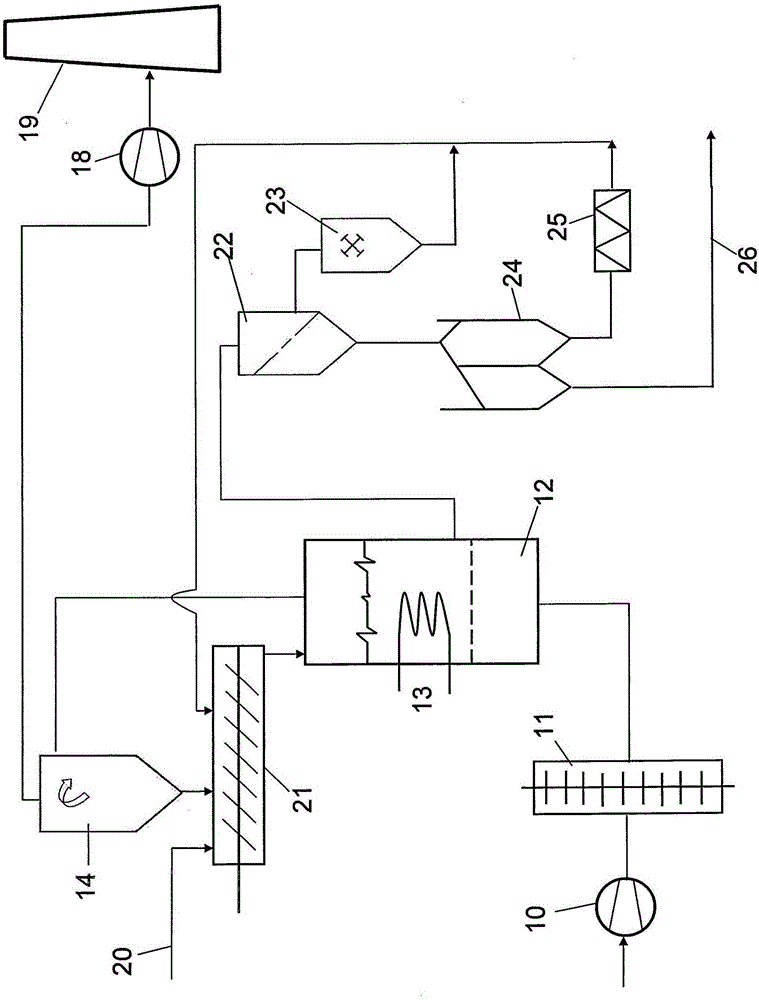

[0025] Blower 10 (see figure 1 ) extrudes the outside air through the hot air conditioner 11 into the drying unit (here a fluidized bed dryer) 12, in which the salt is optionally heated through the heat exchanger 13 and the crystallization water is discharged. The moist dry gas leaves the dryer, is dedusted in a filter or cyclone 14 and after optional additional gas cleaning via a suction fan 18 to the outside 19 . The surface-moistened crystal water-containing salt 20 is dusted in the mixer 21 with the dust deposited from the cyclone or the filter 14 and optionally with the returned product and conveyed to the dryer 12 . After drying, the salt leaves the dryer 12 and oversized particles are separated in an optional screen 22 , ground 23 and fed to a mixer 21 . Part of the material enters the overflow silo 24 , from which optionally the return material for the mixer 21 is withdrawn by means of a dosing screw conveyor 25 and the end product 26 is used for further processing. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com